High-stability laser pumping source with overtemperature protection function

A technology with high stability and protection function, applied in the direction of lasers, laser components, laser monitoring devices, etc., can solve problems such as easy to burn out butterfly lasers, rising, unable to accurately and quickly keep up with changes in electrical signals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 Overall structure of the system

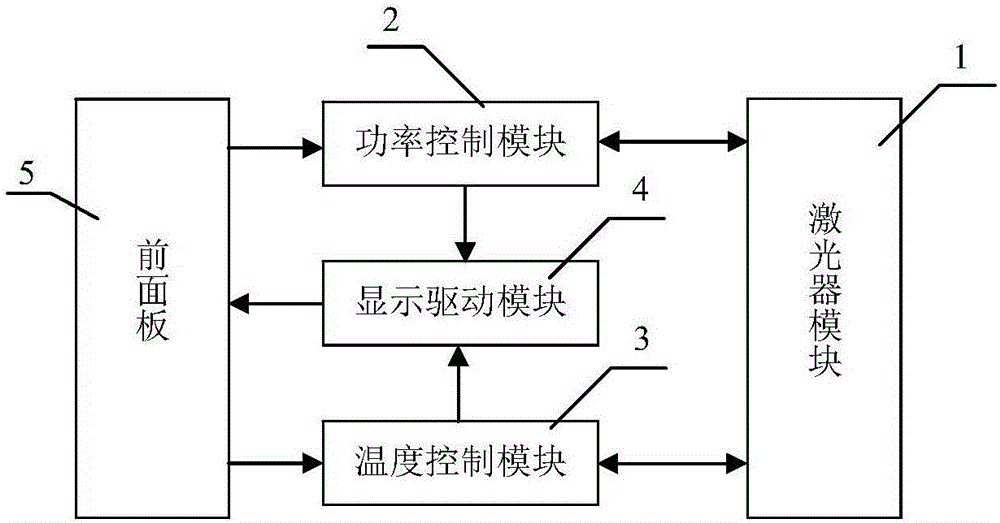

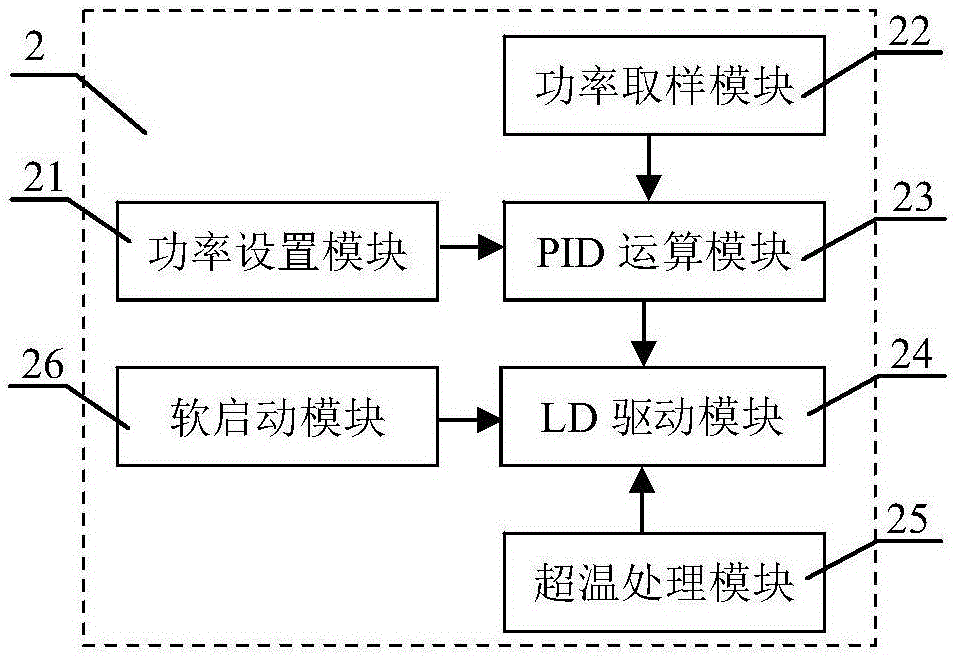

[0035] Such as figure 1 As shown, the system structure includes a laser module 1, a power control module 2, a temperature control module 3 and a display driver module 4, and the structure of the power control module 2 is as follows figure 2 As shown, it is composed of a power setting module 21, a power sampling module 22, a PID operation module 23, an LD drive module 24, an over-temperature processing module 25 and a soft-start module 26, and the power control module 2 and the temperature control module 3 are both connected to the laser module 1 Connected, the power control module 2 provides the drive current to the laser module 1, the size of the output optical power is controlled by the size of the drive current, the required power (output in voltage form) is set by the power setting module 21, and the power sampling module 22 passes through the laser module. The photodiode (PD) integrated in 1 samples the output optica...

Embodiment 2

[0036] Embodiment 2 laser module

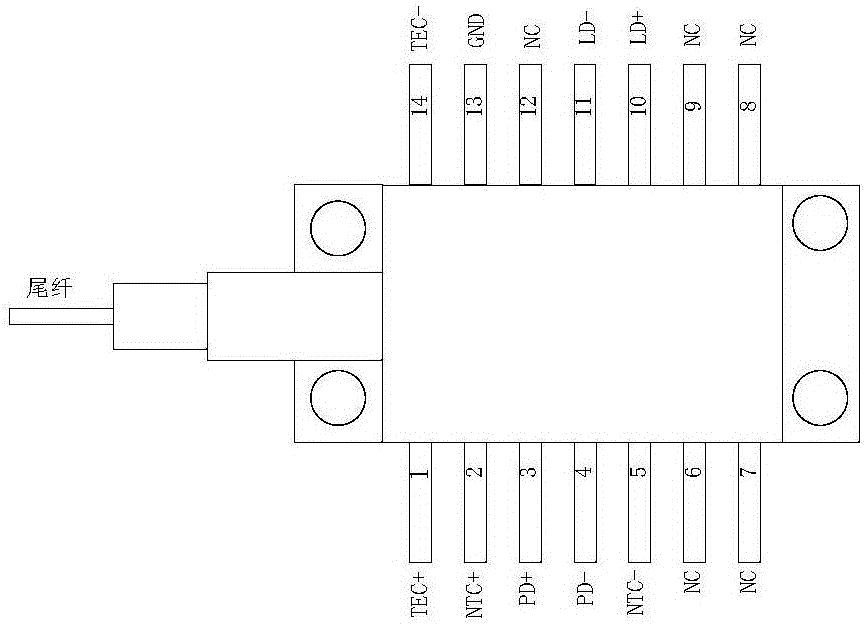

[0037] The laser module 1 of this embodiment selects the laser module of Jie Dixun LC96 butterfly package, and its package and pin schematic diagram are as follows image 3 As shown, the laser module integrates a laser diode LD, a photodiode PD, a thermoelectric cooler TEC, and a thermistor NTC. The pigtail is directly connected to the laser output port on the front panel 5 for outputting laser light. There are 14 in this module pins, of which pins 6, 7, 8, 9, and 12 are empty pins (NC), and pins 1 and 14 are the two current input terminals of the internal thermoelectric cooler (port TEC+ and port TEC -) It is used to connect with the current output port of the temperature control module 3. Pin 2 and pin 5 are two wiring ports (port NTC+ and port NTC-) of the internal integrated thermistor, which are used to connect with the thermal sensor of the temperature control module 3 The resistance input terminal is connected, and the port NTC+ is al...

Embodiment 3

[0038] Embodiment 3 temperature control module

[0039]The temperature control module 3 described in the present invention is a prior art, specifically, Chinese patent CN2007100559129 (high-stability constant temperature controller) or Chinese patent CN2010102701027 (wide power consumption limitation based on thermoelectric cooler) applied by the applicant's research group type constant temperature controller), the temperature control module 3 has a set of current output terminals for driving the thermoelectric cooler for cooling or heating, and the temperature control module 3 also has a set of thermistor input terminals for connecting the thermistor. And the resistance value change of the thermistor (the change in resistance value reflects the change in temperature) is converted into voltage change and fed back to the temperature control module 3 to realize automatic temperature control. The sliding rheostat used to adjust the working temperature in the temperature control mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com