Heavy metal adsorbent for purifying dilute acid and application thereof

An adsorbent, heavy metal technology, applied in the direction of adsorbed water/sewage treatment, other chemical processes, chemical instruments and methods, etc., can solve problems such as decreased effect, reduce water consumption, reduce chemical cost, and overcome the problem of poor treatment effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare heavy metal adsorbent sample 1, the specific method is as follows:

[0034] (1) Get 50 mass parts of dimethyl ammonium dithiocarbamate aqueous solution of 30% mass concentration and drop in the reactor;

[0035] (2) Get 3 parts of sodium sulfite and put it into the reaction kettle, stir and mix;

[0036] (3) Get 30 parts of ammonium sulfide aqueous solution of 17% mass concentration and drop in the reactor, stir and mix;

[0037] (4) Get 15 parts of thiourea aqueous solution of 5% mass concentration and put into the reactor, stir and mix;

[0038] (5) Take 2 parts of tannic acid and put it into the reaction kettle, stir and mix evenly to obtain the heavy metal adsorbent.

Embodiment 2

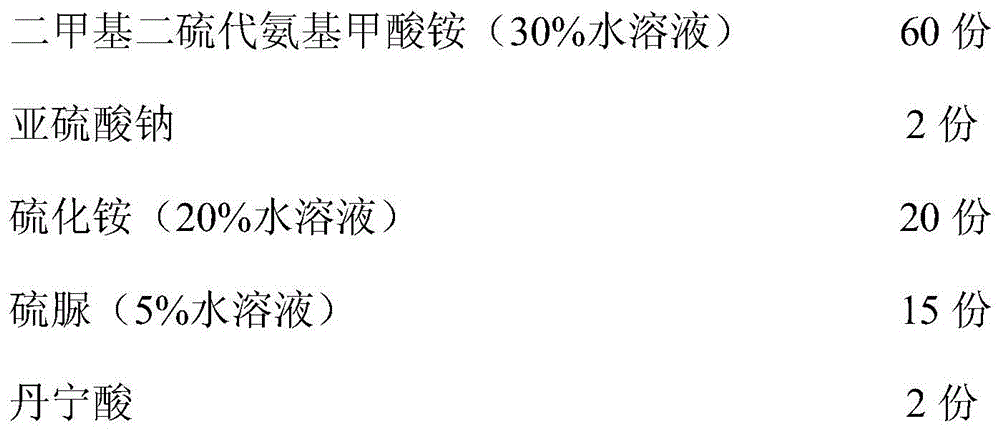

[0040] Repeat embodiment 1, have following difference: prepare heavy metal adsorbent sample 2, raw material is composed of:

[0041]

Embodiment 3

[0043] Repeat embodiment 1, have following difference: prepare heavy metal adsorbent sample 3, raw material is composed of:

[0044]

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com