Method for utilizing industrial waste silica fume to prepare industrial silicon and production system

A technology of industrial waste and micro-silica fume, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of low comprehensive utilization of micro-silica fume and environmental pollution, shorten smelting time, reduce pollution, enhance highly valued effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

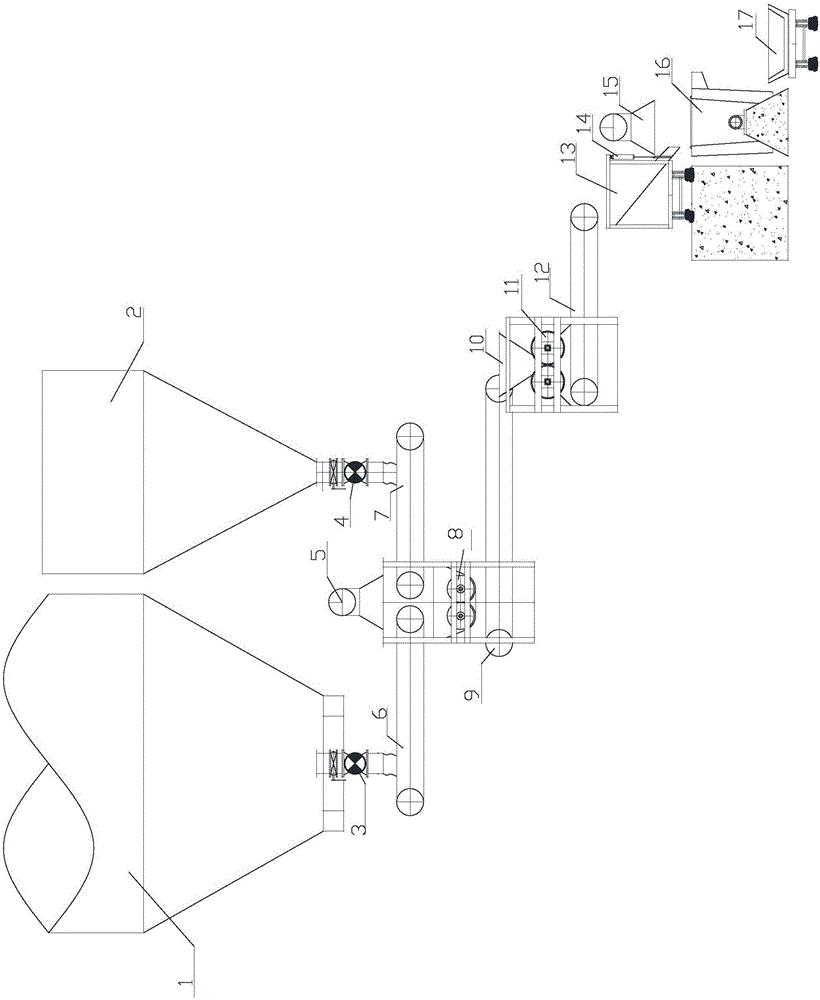

[0039] Such as figure 1 As shown, the present invention provides a method for preparing industrial silicon by using industrial waste micro-silica powder. The raw materials used include 90 kg of micro-silica powder; 36 kg of petroleum coke with an iron content of less than 0.15%; and 9 kg of water.

[0040] The specific steps are:

[0041] In the production system of the present invention, the microsilica powder of the above weight portion is encrypted by a pneumatic encryption machine to 700kg / m 3 The density is sent into the microsilica powder storage encryption bin 1, and the microsilica powder metering and feeding valve 3 at the bottom of the microsilica powder storage encryption bin 1 automatically controls the feeding, and the obtained microsilica powder passes through the microsilica powder conveyor 6 It is transported to the Shuanglong mixing machine 8. At the same time, the reducing agent metering valve 4 at the lower part of the reducing agent storage bin 2 is opened...

Embodiment 2

[0043] Such as figure 1 As shown, the present invention provides a method for preparing industrial silicon by using industrial waste microsilica powder. The raw materials used include 100 kg of microsilica powder; 40 parts of coke powder with an iron content less than 0.15%; 10 parts of water.

[0044] The specific steps are:

[0045] In the production system of the present invention, the micro-silicon powder of the above weight portion is encrypted by a pneumatic fluidized bed encryption machine, and is encrypted to 750kg / m 3 The density is sent into the microsilica powder storage encryption bin 1, and the microsilica powder metering and feeding valve 3 at the bottom of the microsilica powder storage encryption bin 1 automatically controls the feeding, and the obtained microsilica powder passes through the microsilica powder conveyor 6 It is transported to the Shuanglong mixing machine 8. At the same time, the reducing agent metering valve 4 at the lower part of the reducing...

Embodiment 3

[0047] Such as figure 1 As shown, the present invention provides a method for preparing industrial silicon by using industrial waste microsilica powder. The raw materials used include 110 parts of microsilica fume; 55 parts of raw coal with an iron content less than 0.15%; 11 parts of water.

[0048] The specific steps are:

[0049] In the production system of the present invention, the microsilica powder of the above weight portion is encrypted by a pneumatic encryption machine to 800kg / m 3 The density is sent into the microsilica powder storage encryption bin 1, and the microsilica powder metering and feeding valve 3 at the bottom of the microsilica powder storage encryption bin 1 automatically controls the feeding, and the obtained microsilica powder passes through the microsilica powder conveyor 6 It is transported to the Shuanglong mixing machine 8. At the same time, the reducing agent metering valve 4 at the lower part of the reducing agent storage bin 2 is opened. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com