Method for preparing Ti2PbC ceramic by powder metallurgy method

A technology of powder metallurgy and means, which is applied in the field of preparation of metallic ceramic materials, can solve the problems of incomplete performance research, complicated preparation methods, high cost, etc., and achieve the effects of wide range of process parameters, high purity of MAX phase, and reduced preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

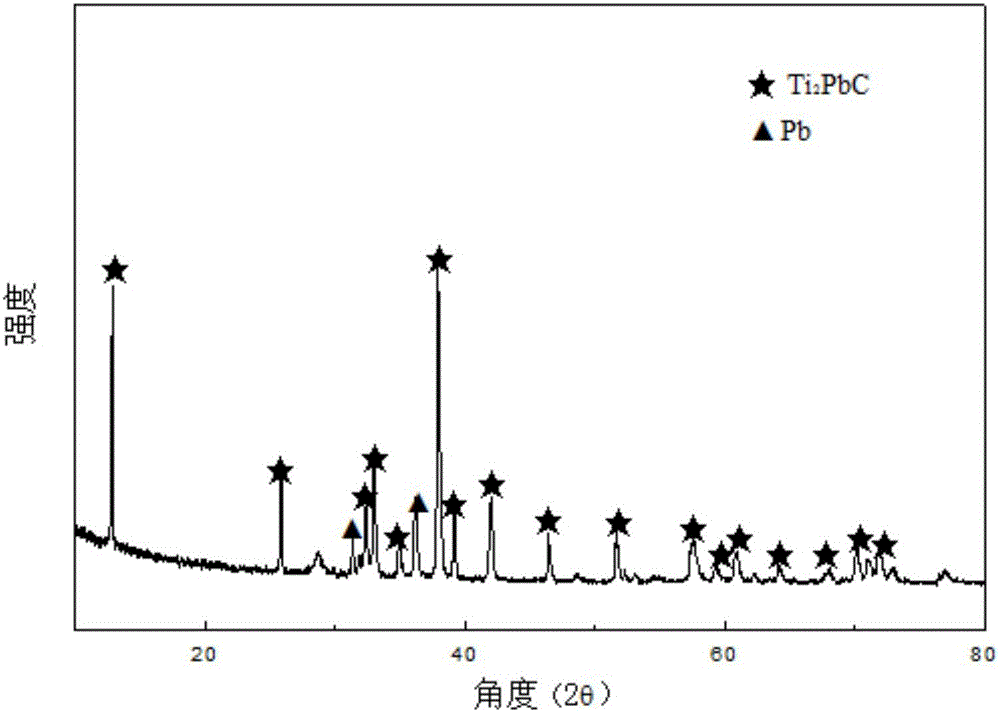

[0023] According to the molar ratio of Ti:TiC:Pb=1:1:1.2, weigh 4.04 grams of Ti powder, 5.05 grams of TiC powder, and 20.91 grams of lead powder, put them into a plastic bottle, and mix them on a powder mixer for 40 hours. Put the mixed powder into an ordinary tube furnace under Ar atmosphere or vacuum protection, heat up to 1500°C at a heating rate of 10°C / min, keep it for 200min, and cool down with the furnace to obtain high-purity Ti2PbC ceramics.

Embodiment approach 2

[0025] According to the molar ratio of Ti:TiC:Pb=1:1:1.1, weigh 4.28 grams of Ti powder, 5.36 grams of TiC powder, and 20.35 grams of lead powder, put them into plastic bottles, and mix them on a powder mixer for 50 hours. Put the mixed powder into an ordinary tube furnace, Ar atmosphere or vacuum protection, raise the temperature to 1450°C at a heating rate of 10°C / min, and keep it for 120min to prepare high-purity Ti2PbC ceramics.

Embodiment approach 3

[0027] According to the molar ratio of Ti:TiC:Pb=1:1:1, weigh 4.57 grams of Ti powder, 5.71 grams of TiC powder, and 19.71 grams of lead powder, put them into plastic bottles, and mix them on a powder mixer for 50 hours. Put the mixed powder into an ordinary tube furnace, Ar atmosphere or vacuum protection, raise the temperature to 1200°C at a heating rate of 15°C / min, and keep it for 150min to prepare high-purity Ti2PbC ceramics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com