Plastic-plastic compound waterborne bi-component adhesive

A two-component, adhesive technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of environmental protection, solvent emission pollution, unsafety, etc., and achieve high production efficiency , Short curing time and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

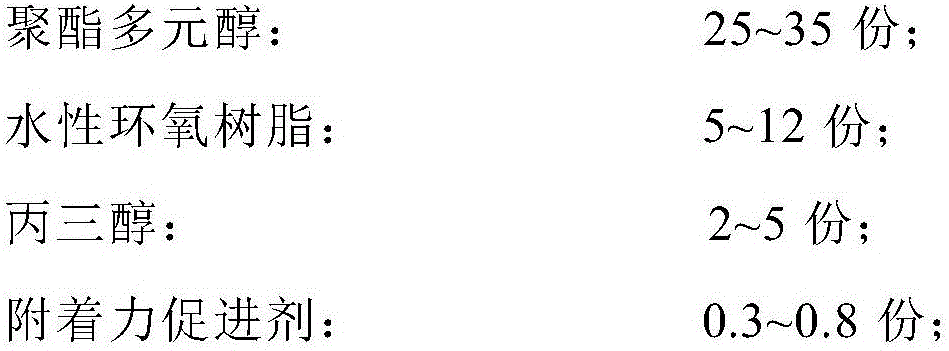

[0028] This example relates to a high-temperature retortable water-based two-component adhesive suitable for plastic-plastic composites. The coating is made of the following components and contents as raw materials:

[0029]

Embodiment 2

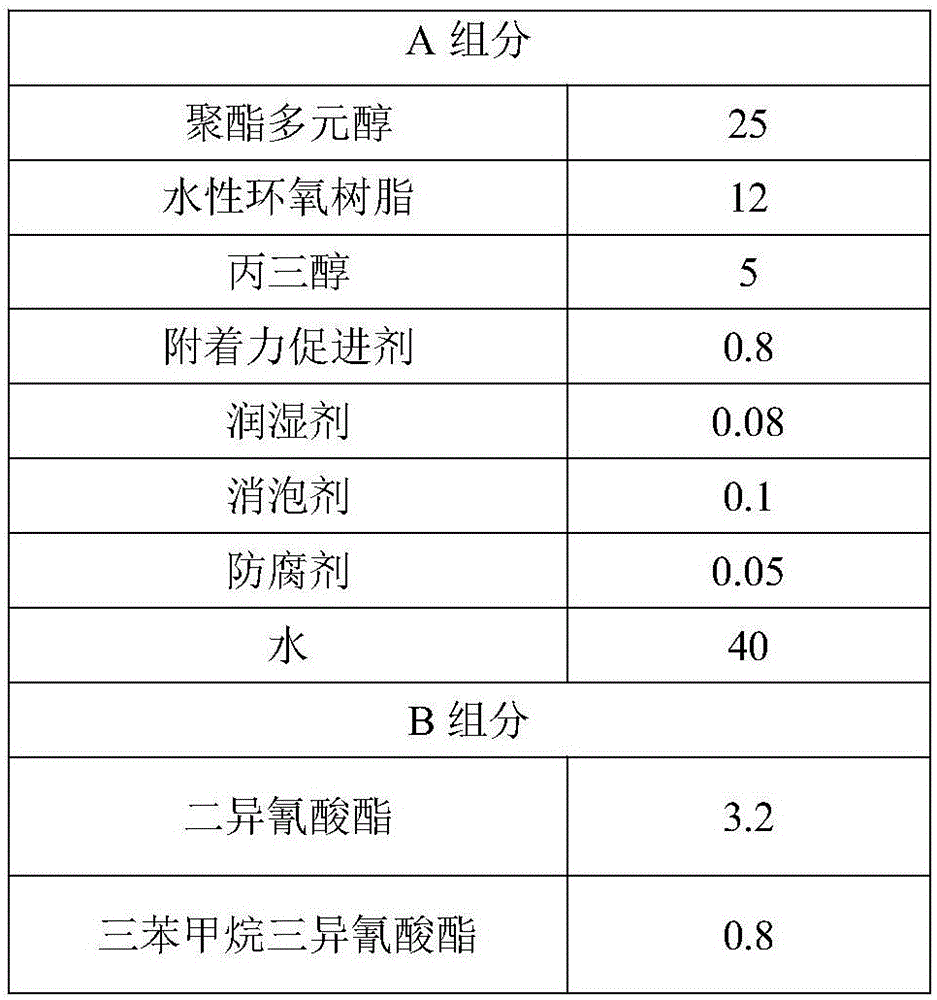

[0031] This example relates to a high-temperature retortable water-based two-component adhesive suitable for plastic-plastic composites. The coating is made of the following components and contents as raw materials:

[0032]

[0033]

Embodiment 3

[0035] This example relates to a high-temperature retortable water-based two-component adhesive suitable for plastic-plastic composites. The coating is made of the following components and contents as raw materials:

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com