Compound hydrate inhibitor

A hydrate inhibitor, a composite technology, which is applied to drilling compositions, pipeline systems, chemical instruments and methods, etc., can solve the problems of high cost, difficult recovery, high price, etc., and achieve good anti-aggregation effect and effect. Good effect, good inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

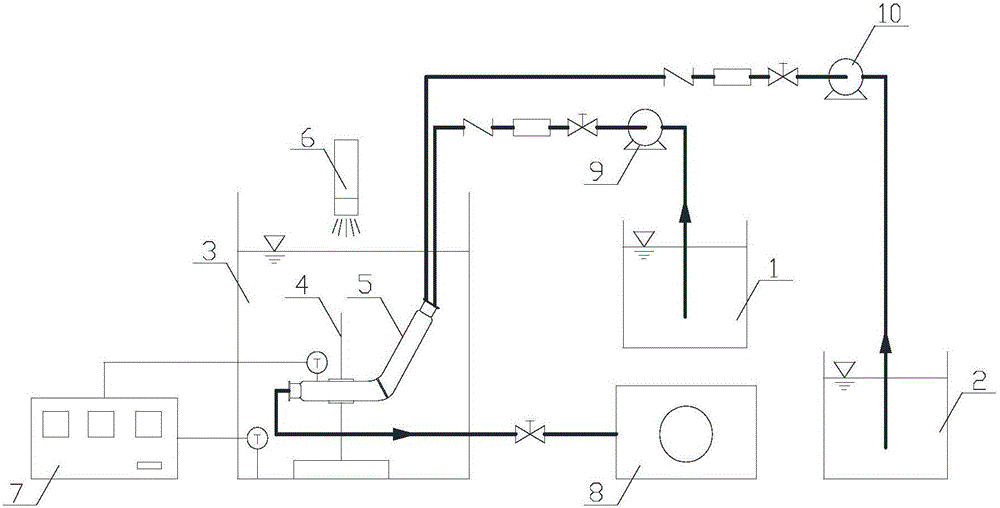

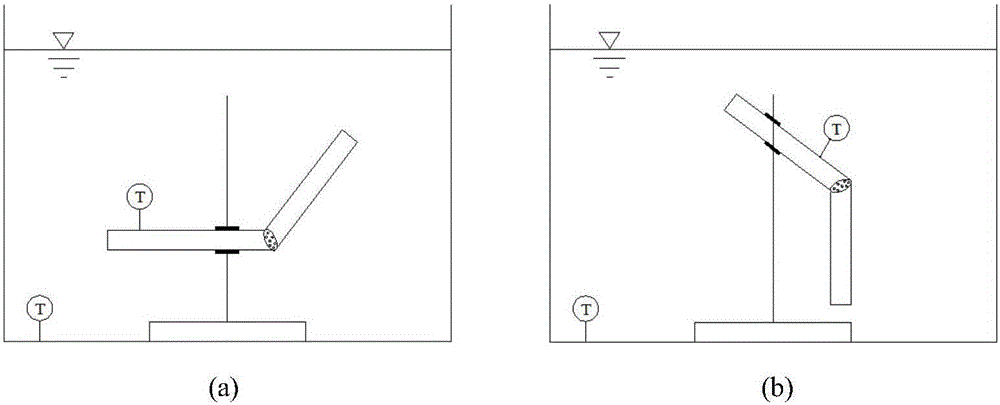

[0014] The preparation device adopted in the present invention comprises a visualized reactor and a low-temperature constant-temperature water bath. The reactor is composed of a hydrate forming section and a water storage section made of transparent glass, and the volume of each section is 40ml. The angle between the two sections is 110°, and a glass screen is installed in the middle. The initially injected solution is located in the hydrate formation section; when hydrate formation is performed, the water storage section is on the top, and the formation section is on the bottom, so that the generated hydrate is located in the formation section; when the decomposition experiment is performed, the water storage section of the formation section is located on the top , the water storage section is located below, and the water produced by hydrate decomposition can flow into the water storage section through the glass sieve under the action of gravity, while the agglomerated hydrat...

Embodiment 1

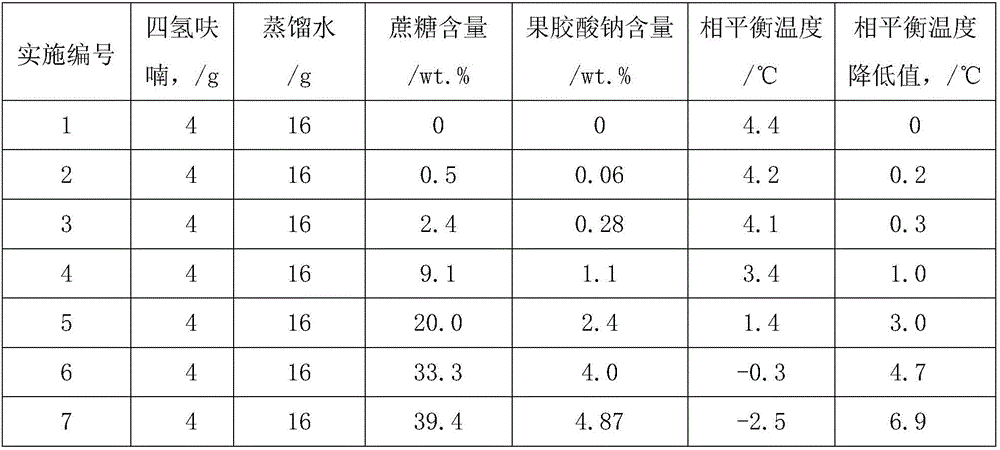

[0031] Take 20g of tetrahydrofuran, 80g of distilled water, 0.5% of sucrose and 0.06% of sodium pectate in distilled water; add sodium pectate into distilled water and heat to 40°C, stir at 1200 rpm for 20 to 25 minutes, then add Stir the sucrose for another 3 to 5 minutes to obtain the hydrate inhibitor; add tetrahydrofuran and the hydrate inhibitor into the reaction vessel; carry out the experiment according to the above-mentioned experimental procedure, and obtain the phase equilibrium temperature of the hydrate is 4.2°C, which is the same as that without the compound inhibitor The phase equilibrium temperature of the hydrate formed in the system is 0.2℃ lower than that.

Embodiment 2

[0033] Take 20g of tetrahydrofuran, 80g of distilled water, 39.4% of sucrose and 4.87% of sodium pectate in distilled water; add sodium pectate into distilled water and heat to 40°C, stir at 1200 rpm for 20 to 25 minutes, then add Stir the sucrose for another 3 to 10 minutes to obtain the hydrate inhibitor; add tetrahydrofuran and the hydrate inhibitor into the reaction vessel; carry out the experiment according to the above-mentioned experimental procedure, and obtain the phase equilibrium temperature of the hydrate is -2.5°C, which is comparable to that of the non-composite type The phase equilibrium temperature of the hydrate formed by the inhibitory system is 6.9℃ lower than that.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com