WC/Fe-based argon arc cladding alloy powder

A technology of argon arc cladding and alloy powder, which is applied in the field of materials to achieve the effects of low cost, wide use and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

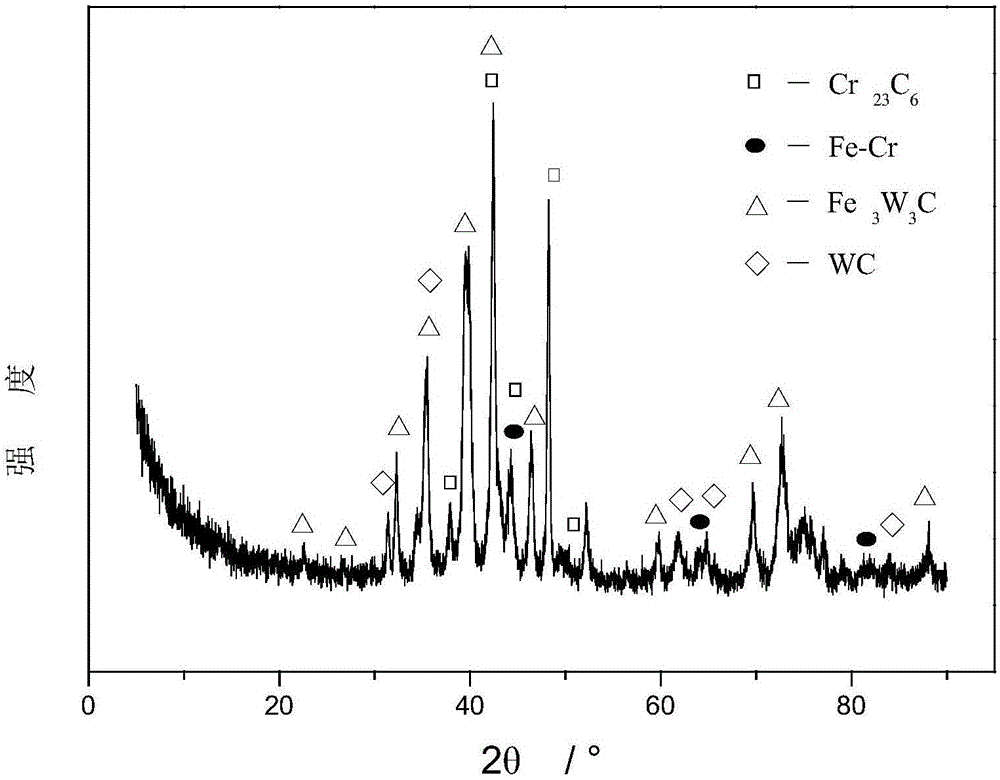

[0031] WC / Fe-based alloy powder for argon arc cladding, in terms of mass percentage, its composition ratio is: 20% high-carbon ferrochromium, 2% high-carbon ferromanganese, 45% WC powder, and the balance is iron and unavoidable Impurities.

[0032] Pour the above-mentioned powder raw materials into a mortar, grind until the alloy powder is uniform, add a little water glass as a binder, wet mix the alloy powder, and evenly coat the surface of the preset block, let it dry in the shade for 24 hours, then Put it into a drying oven, heat up to 100-150°C, and dry for 2-4 hours; set up an argon arc welding machine for cladding, adjust the cladding current to 120A, argon gas flow rate to 8L / min, and speed to 120mm / min; After the cladding is completed, relevant inspections are carried out on the coating.

Embodiment 2

[0034] WC / Fe-based alloy powder for argon arc cladding, in terms of mass percentage, its composition ratio is: 16% high-carbon ferrochromium, 1.5% high-carbon ferromanganese, 50% WC powder, and the balance is iron and unavoidable Impurities.

[0035] Mill the above powder raw materials with a ball mill for 2 to 8 minutes, add a little water glass as a binder, wet mix the alloy powder, and evenly coat the surface of the preset block, let it dry in the shade for 24 hours, and then put it in the oven. In the box, heat up to 100-150°C and dry for 2-4 hours; set up an argon arc welding machine for cladding, adjust the cladding current to 120A, argon gas flow rate to 12L / min, and speed to 120mm / min; after cladding is completed , after the surface is slightly polished, the relevant inspection is carried out on the coating.

Embodiment 3

[0037] WC / Fe-based alloy powder for argon arc cladding, in terms of mass percentage, its composition ratio is: high-carbon ferrochrome 13%, high-carbon ferromanganese 1.5%, WC powder 55%, the balance is iron and unavoidable Impurities.

[0038] Pour the above-mentioned powder raw materials into a mortar, grind until the alloy powder is uniform, add a little water glass as a binder, wet mix the alloy powder, and evenly coat the surface of the preset block, let it dry in the shade for 24 hours, then Put it into a drying oven, heat up to 100-150°C, and dry for 2-4 hours; set up an argon arc welding machine for cladding, adjust the cladding current to 120A, argon gas flow rate to 8L / min, and speed to 120mm / min; After the cladding is completed, relevant inspections are carried out on the coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com