Wool-aloe fiber blended fabric for auto-inner ornament

A technology of aloe vera fiber and blended fabric, which is applied in fiber treatment, animal fiber, wear-resistant fiber, etc. It can solve the problems of poor light stability, easy color change, and low light fastness of wool, so as to achieve easy dyeing and eliminate Skin feeling overheated in summer, effect of improving hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

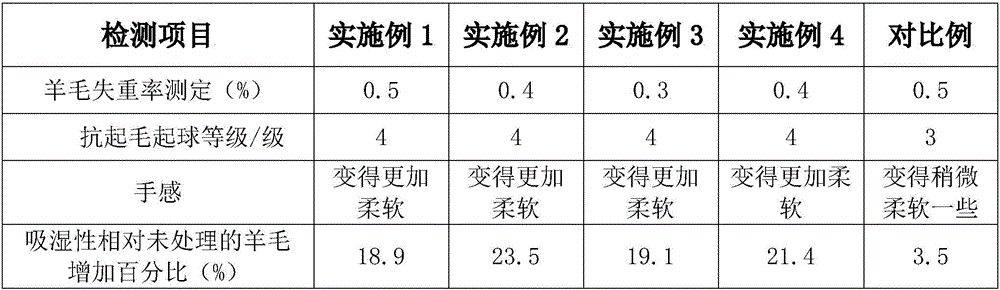

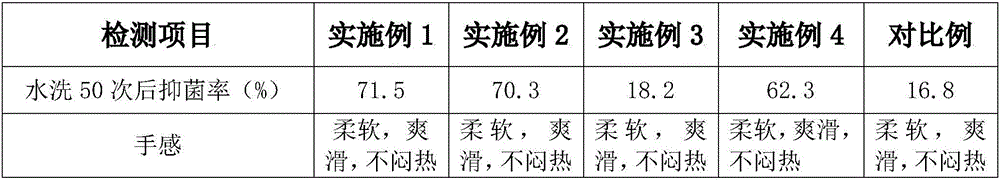

Examples

Embodiment 1

[0034] A kind of wool and aloe fiber blended fabric for automobile interior decoration, its preparation method is as follows:

[0035] (1) Wool fiber washing pretreatment:

[0036] Select high-quality wool fibers and perform three washing pretreatments:

[0037] The first time: 0.5% citric acid, the water temperature is kept at 45°C; the pH is controlled at 7, and the treatment time is 30 minutes;

[0038] The second time: 1.2% glucoamylase, the water temperature was kept at 35°C; the pH was controlled at 7, and the treatment time was 10 minutes;

[0039] The third time: Rinse with pure water, control the temperature at 55°C, and dry at low temperature;

[0040] Washed pre-treated wool fibers have been freed of various dirt and chemically altered;

[0041] (2) Microbial fermentation treatment:

[0042] Acetobacter, Lactobacillus acidophilus, and Bacillus amyloliquefaciens were prepared according to the ratio of 1:0.3:0.7 to 1.1*10 5 The bacterial suspension, the bacterial...

Embodiment 2

[0052] A kind of wool and aloe fiber blended fabric for automobile interior decoration, its preparation method is as follows:

[0053](1) Wool fiber washing pretreatment:

[0054] Select high-quality wool fibers and perform three washing pretreatments:

[0055] The first time: 0.8% citric acid, the water temperature was kept at 45°C; the pH was controlled at 7, and the treatment time was 30 minutes;

[0056] The second time: 0.8% glucoamylase, the water temperature was kept at 35°C; the pH was controlled at 7, and the treatment time was 10 minutes;

[0057] The third time: Rinse with pure water, control the temperature at 55°C, and dry at low temperature;

[0058] Washed pre-treated wool fibers have been freed of various dirt and chemically altered;

[0059] (2) Microbial fermentation treatment:

[0060] Acetobacter, Lactobacillus acidophilus, and Bacillus amyloliquefaciens were prepared according to the strain ratio of 1:0.5:0.5 to make 1.1*10 5 The bacterial suspension,...

Embodiment 3

[0070] A kind of wool and aloe fiber blended fabric for automobile interior decoration, its preparation method is as follows:

[0071] (1) Wool fiber washing pretreatment:

[0072] Select high-quality wool fibers and perform three washing pretreatments:

[0073] The first time: 0.6% citric acid, the water temperature was kept at 45°C; the pH was controlled at 7, and the treatment time was 30 minutes;

[0074] The second time: 1.1% glucoamylase, the water temperature was kept at 35°C; the pH was controlled at 7, and the treatment time was 10 minutes;

[0075] The third time: Rinse with pure water, control the temperature at 55°C, and dry at low temperature;

[0076] Washed pre-treated wool fibers have been freed of various dirt and chemically altered;

[0077] (2) Microbial fermentation treatment:

[0078] Acetobacter, Lactobacillus acidophilus, and Bacillus amyloliquefaciens were prepared according to the ratio of 1:0.4:0.6 to 1.1*10 5 The bacterial suspension, the bacter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com