Electric supercharging non-backflow Atkinson cycle gasoline engine system

A gasoline engine, Atkinson's technology, applied to engine components, combustion engines, engine control, etc., can solve the problem of affecting the uniformity and turbulence of the mixture in the cylinder, reducing the effective charge of the mixture in the cylinder, reducing combustion efficiency and Thermal efficiency and other issues, to achieve the effect of expanding high-efficiency working area, improving power performance, and suppressing knocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

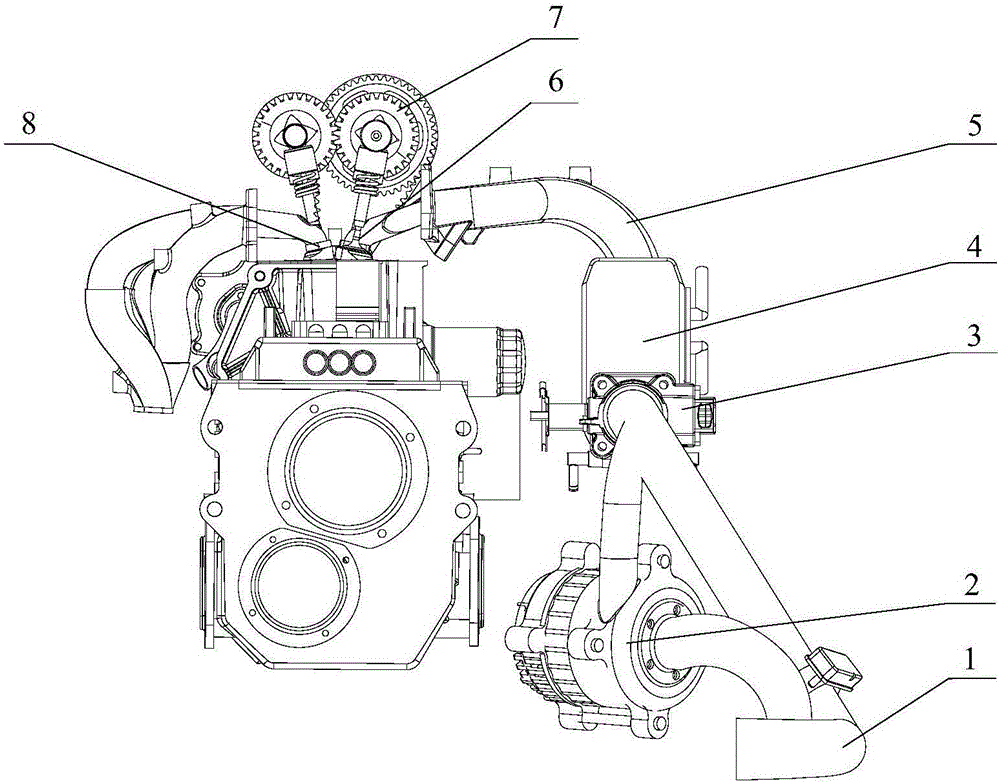

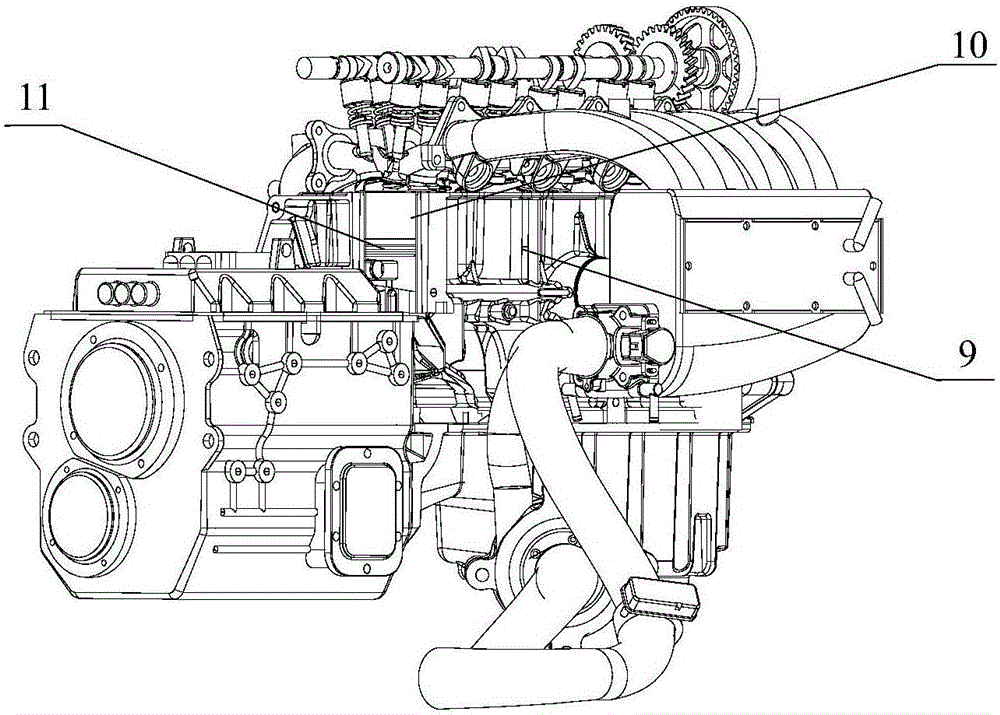

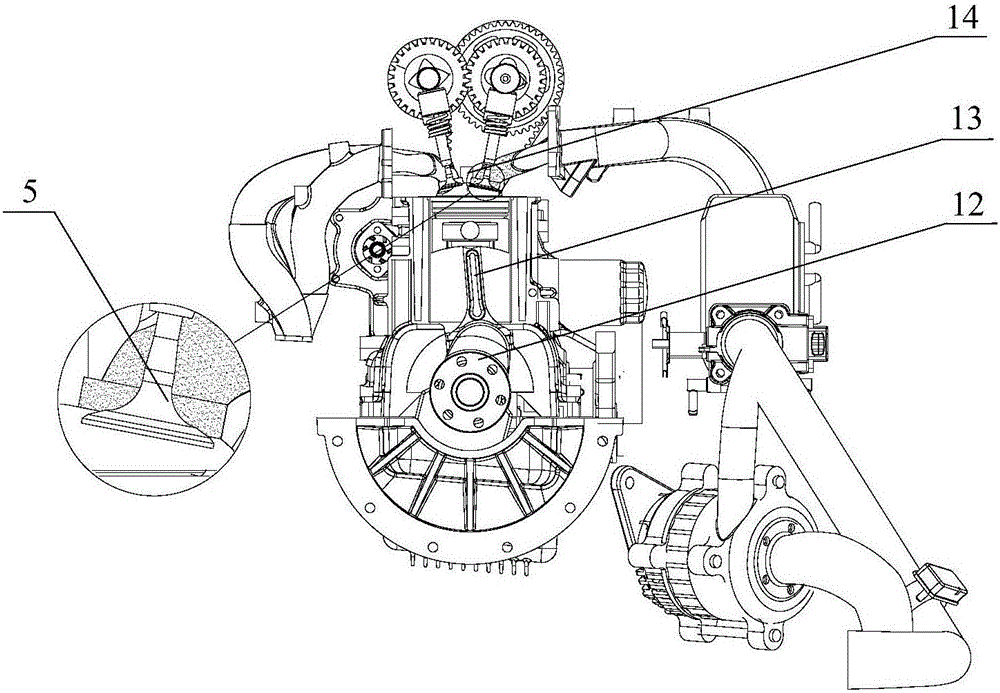

[0012] figure 1 It is a front view of the structure of the electric supercharged non-return Atkinson cycle gasoline engine system of the present invention, figure 2 It is a 45° view on the right side of the structure of the electric supercharged non-return Atkinson cycle gasoline engine system of the present invention. As shown in the figure, the electric supercharged Atkinson cycle gasoline engine system device of this embodiment mainly includes: intake pipe 1, Electric supercharger 2, throttle valve 3, water-cooled intercooler 4, intake valve 6, exhaust valve 8, valve timing mechanism 7, piston 11, engine block 9, cylinder 10, connecting rod 13, crankshaft 12, spark plug 14. The electric supercharger 2 is arranged at the front end of the water-cooled intercooler 4; the outlet of the electric supercharger communicates with the inlet of the water-cooled intercooler 4 through the throttle valve 3; the outlet of the water-cooled intercooler 4 passes through the intake pipe 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com