Method for measuring length of heat-affected zone of 617 nickel-based alloy

A heat-affected zone, nickel-based alloy technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problem of difficult heat-affected zone length and achieve the effect of accurate measurement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The base material of the welded joint in this embodiment is 617 nickel-based alloy plate, the filler wire is ENiCrCoMo-1, and the welding method is argon tungsten arc narrow gap welding with heat treatment after welding. The length of the heat-affected zone of the 617 nickel-based alloy is measured by the following steps:

[0038] Step 1: the preparation of described metallographic sample is made by the following steps:

[0039] (1) Wire cutting: design the size of the welded joint of the 617 nickel-based alloy described by wire cutting according to the length of the mosaic machine sample, and the wire cutting size is a welded joint sample of 25mm×12mm×5mm;

[0040] (2) Thermal mounting: ultrasonically clean the sample to remove surface oil, and then mount the sample with a thermal mounting machine to obtain a mounting sample with a diameter of 30 mm and a thickness of 13 mm;

[0041] (3) Coarse grinding and fine grinding: Use water sandpaper with a particle size of 18...

Embodiment 2

[0047] The base metal of the welded joint in this embodiment is 617 nickel-based alloy plate, the filler wire is ENiCrCoMo-1, and the welding method adopts argon tungsten arc narrow gap welding without heat treatment after welding. The length measurement steps 1 and 2 of the heat-affected zone of the 617 nickel-based alloy are the same as in Example 1.

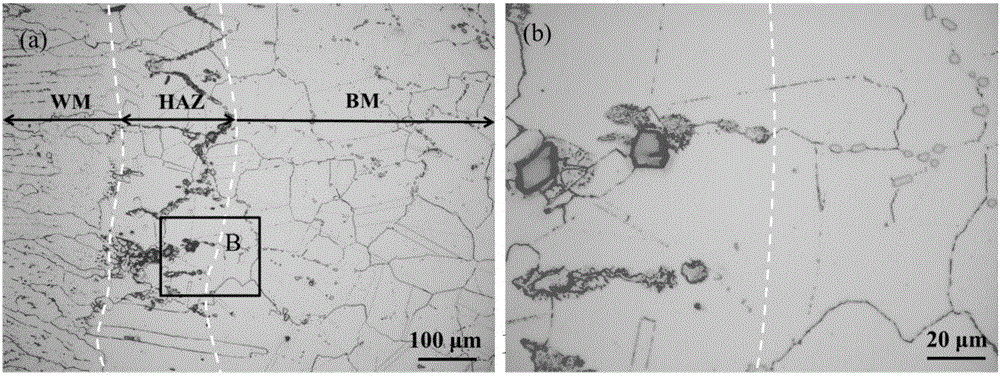

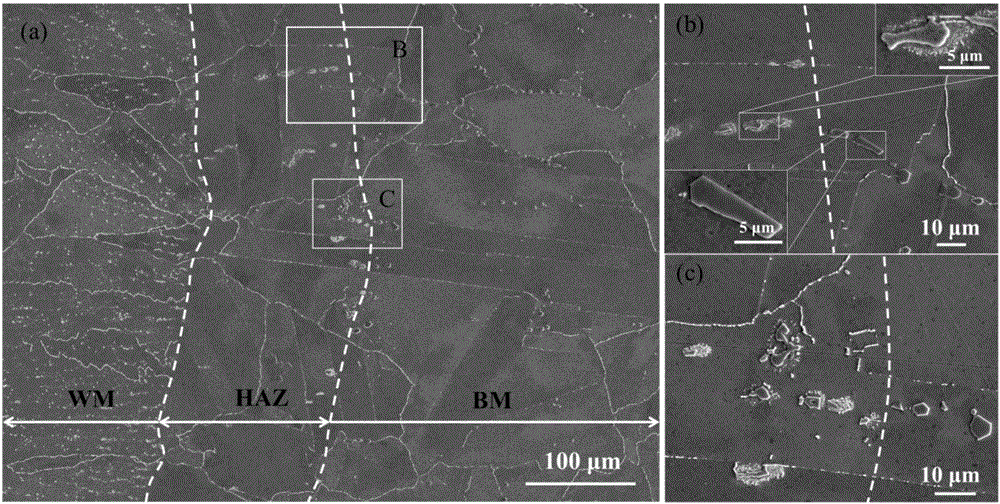

[0048] Observing the near-seam area of the welded joint of the metallographic sample through an optical microscope or a scanning electron microscope, it can be observed that the morphology of carbides in the heat-affected zone has changed significantly compared to that of the base metal under a magnification of 1000 times. The carbides of the base metal are polygonal regular shapes, while the carbides in the heat-affected zone are irregular shapes, and herpes-like (under light microscope observation) or concave-shaped (under electron microscope observation) rings can also be observed around the carbides in the heat-affected z...

Embodiment 3

[0050] The base metal of the welded joint in this embodiment is a 617 nickel-based alloy plate, and the welding method is fiber laser welding and heat treatment is performed after welding. The length measurement steps 1 and 2 of the heat-affected zone of the 617 nickel-based alloy are the same as in Example 1.

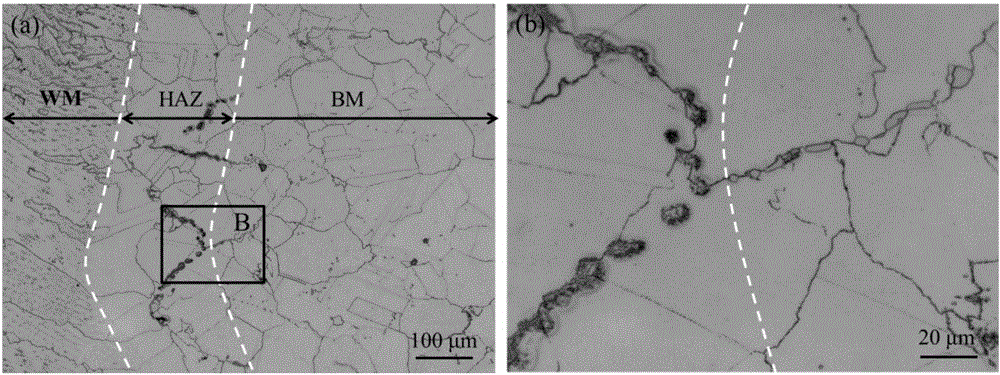

[0051] Observing the near-seam area of the welded joint of the metallographic sample through an optical microscope or a scanning electron microscope, it can be observed that the morphology of carbides in the heat-affected zone has changed significantly compared to that of the base metal under a magnification of 1000 times. The carbides in the base metal are polygonal regular shapes, while the carbides in the heat-affected zone are irregular in shape, and small particles will be precipitated around the carbides in the heat-affected zone. Therefore it can be determined that the boundary (such as Figure 5 The white dotted line on the right side of a), the boundary lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com