Three-dimensional locally-resonant photonic crystal structure and preparation method

A phononic crystal and local resonance technology, which is applied in the field of local resonance phononic crystal structure and preparation, can solve problems such as difficulty in preparing complex three-dimensional phononic crystal structures, and achieves reduced structure size, reduced structure weight, and simple preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific examples.

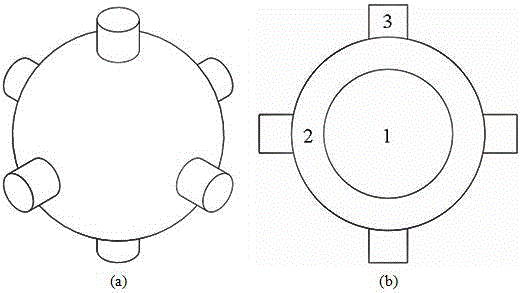

[0029] figure 1 (a) is the unit cell model of the phononic crystal structure, including core 1, cladding layer 2, and connector 3. Such as figure 1 As shown in (b), the unit cell contains six connectors 3 , and the central axes of the connectors 3 intersect with the center of the core 1 .

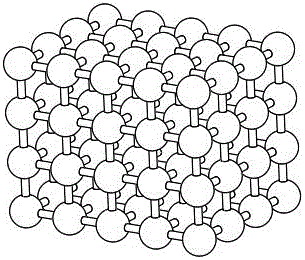

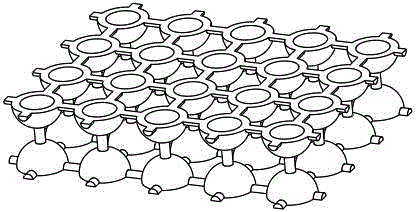

[0030] The core 1 and the cladding layer 2 form scattering units and are periodically arranged in a square lattice, and the scattering units are connected by connectors 3 to form a complete three-dimensional phononic crystal structure with a certain number of periods, such as figure 2 shown.

[0031] The preparation method of the present invention is specifically described in conjunction with the accompanying drawings, including the following six steps.

[0032] Step 1), the design of the structure size: the lattice constant is determined by the req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com