Three-dimensional nanometer porous copper/two-dimensional cuprous oxide nanosheet array type lithium ion battery negative electrode and one-step preparation method thereof

A nanosheet array and lithium-ion battery technology, which is applied in battery electrodes, secondary batteries, nanotechnology, etc., can solve problems such as complex structure, reduced specific capacity, and reduced cycle performance of lithium-ion batteries, achieving controllability, speed up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

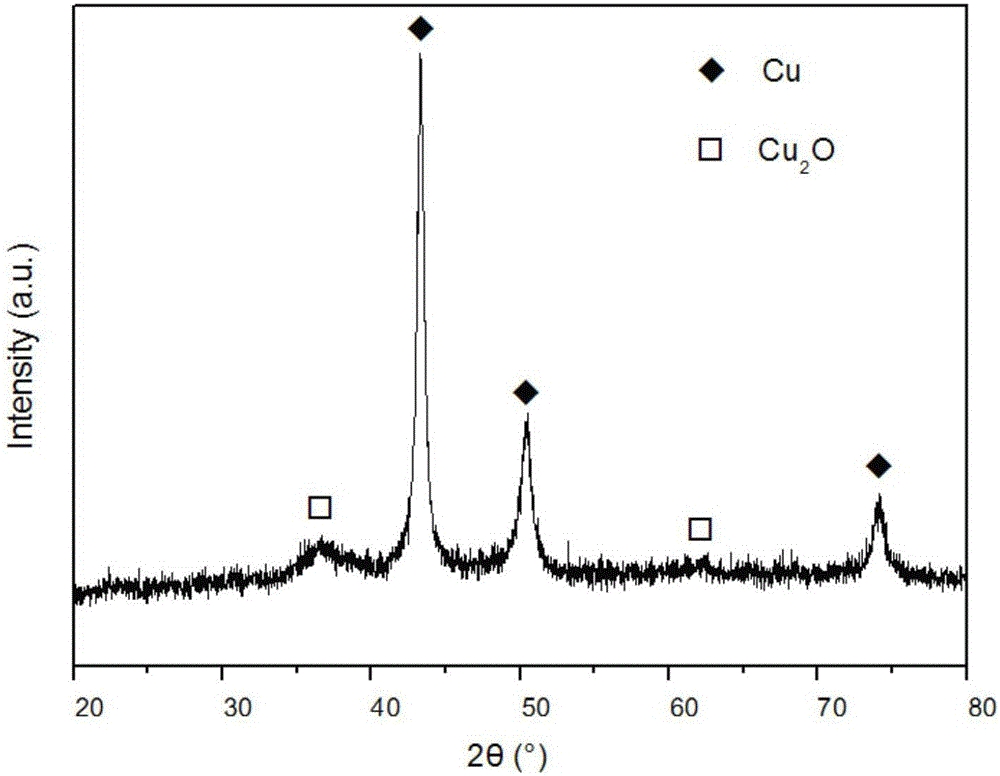

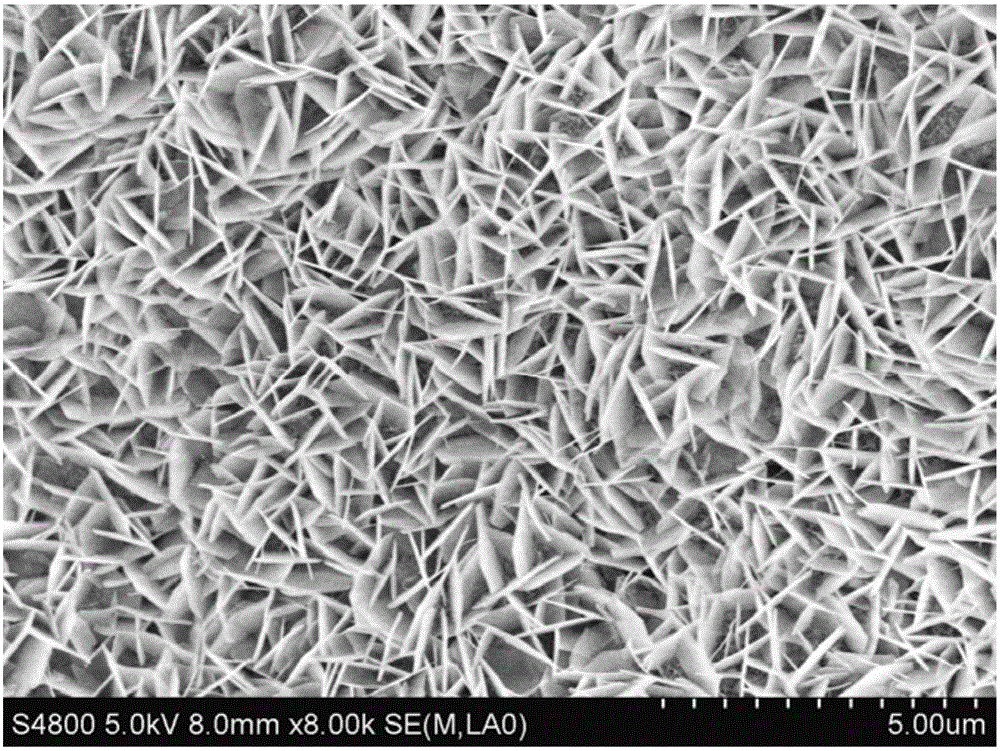

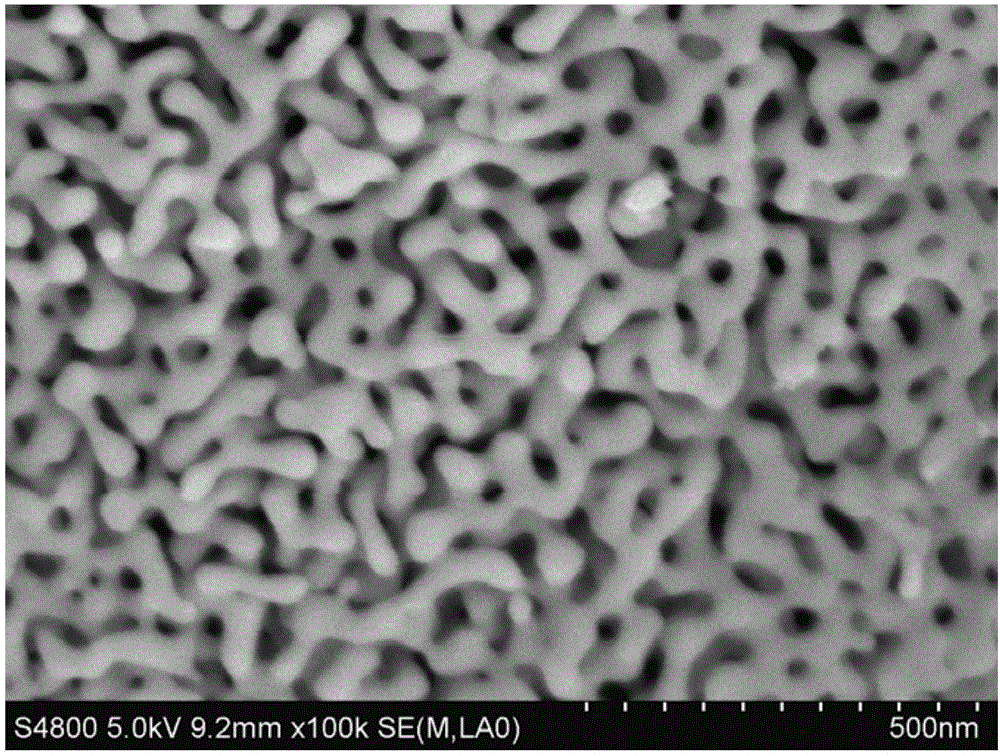

[0031] In this example, the preparation method of the negative electrode of the three-dimensional nanoporous copper / two-dimensional cuprous oxide nanosheet array type lithium-ion battery is as follows:

[0032] Copper-manganese alloy blocks with 50% atomic percentage of copper and manganese are wire-cut into copper-manganese alloy sheets with a thickness of 0.4mm with a wire cutting machine, and the copper-manganese alloy sheets are successively sanded with 380 mesh, 800 mesh, 1200 mesh, and 2000 mesh water sandpaper. The surface of the alloy sheet was polished, and then polished with a diamond polishing paste with a particle size of 0.5 μm. The polished copper-manganese alloy sheet was placed in an ultrasonic cleaner, ultrasonically cleaned with absolute ethanol at 100W for 2 minutes, taken out and left to air naturally. Dry.

[0033] With the above-mentioned copper-manganese alloy sheet as the working electrode, the saturated calomel electrode as the reference electrode, and...

Embodiment 2

[0038] In this example, the preparation method of the negative electrode of the three-dimensional nanoporous copper / two-dimensional cuprous oxide nanosheet array type lithium-ion battery is as follows:

[0039] A copper-manganese alloy block with a copper atomic percentage of 10% and a manganese atomic percentage of 90% is wire-cut into copper-manganese alloy sheets with a thickness of 0.1mm with a wire cutting machine, and water of 380 mesh, 800 mesh, 1200 mesh, and 2000 mesh is sequentially used The surface of the copper-manganese alloy sheet is polished with sandpaper, and then polished with a diamond polishing paste with a particle size of 0.5 μm. The polished copper-manganese alloy sheet is placed in an ultrasonic cleaner, and ultrasonically cleaned with absolute ethanol at 100W for 3 minutes. Take it out and let it dry naturally.

[0040] With the above-mentioned copper-manganese alloy sheet as the working electrode, the saturated calomel electrode as the reference elect...

Embodiment 3

[0044] In this example, the preparation method of the negative electrode of the three-dimensional nanoporous copper / two-dimensional cuprous oxide nanosheet array type lithium-ion battery is as follows:

[0045] A copper-manganese alloy block with a copper atomic percentage of 80% and a manganese atomic percentage of 20% is cut into copper-manganese alloy sheets with a thickness of 0.6mm by a wire cutting machine. The surface of the copper-manganese alloy sheet is polished with sandpaper, and then polished with a diamond polishing paste with a particle size of 0.5 μm. The polished copper-manganese alloy sheet is placed in an ultrasonic cleaner, and ultrasonically cleaned with absolute ethanol at 100W for 5 minutes. Take it out and let it dry naturally.

[0046] With the above-mentioned copper-manganese alloy sheet as the working electrode, the saturated calomel electrode as the reference electrode, and the platinum electrode as the auxiliary electrode, the working electrode, re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com