Method for preparing self-doped double-function oxygen reaction electrocatalyst

An electrocatalyst and self-doping technology, used in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems such as environmental pollution, reduce environmental pollution, High yield, performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

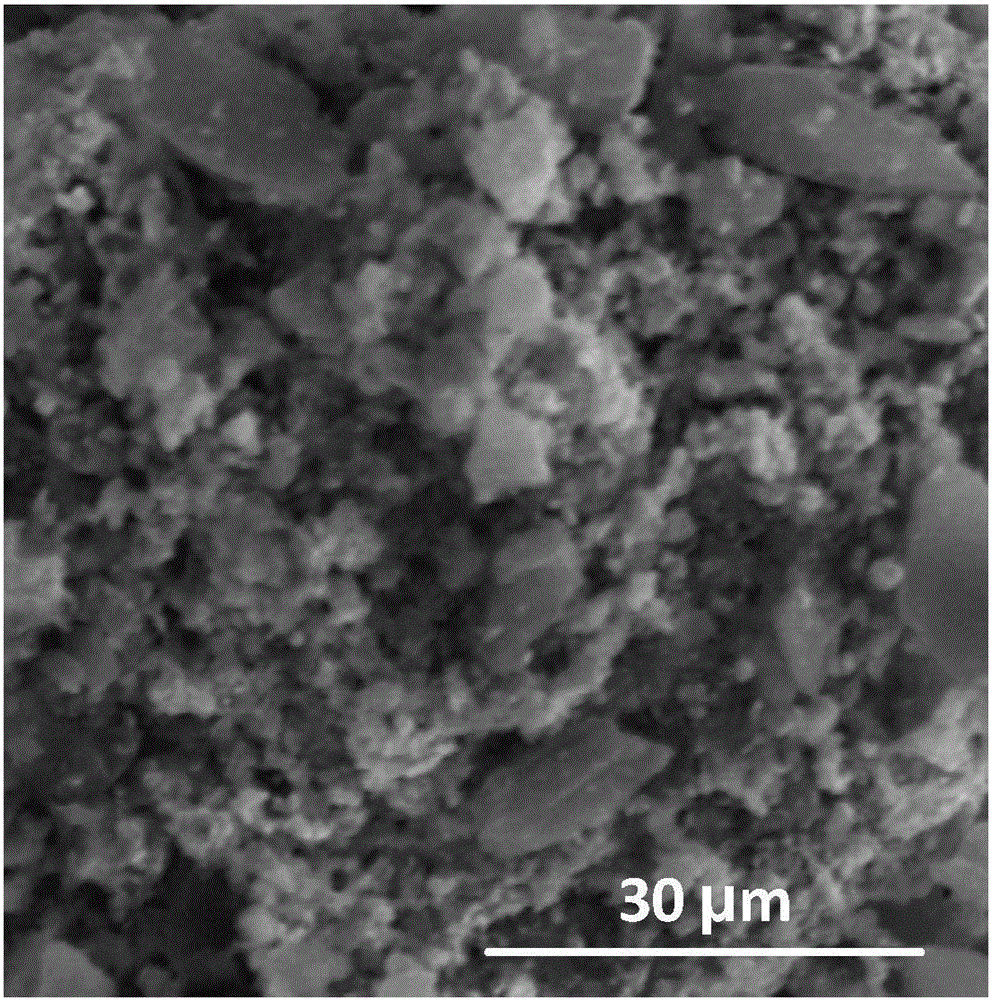

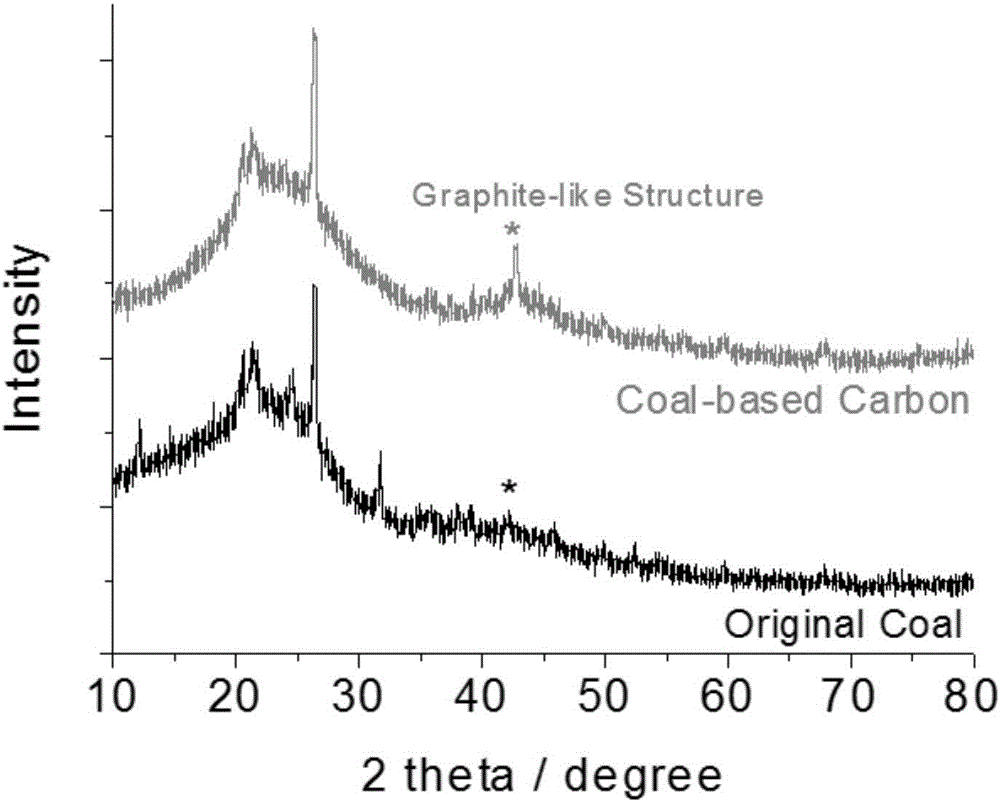

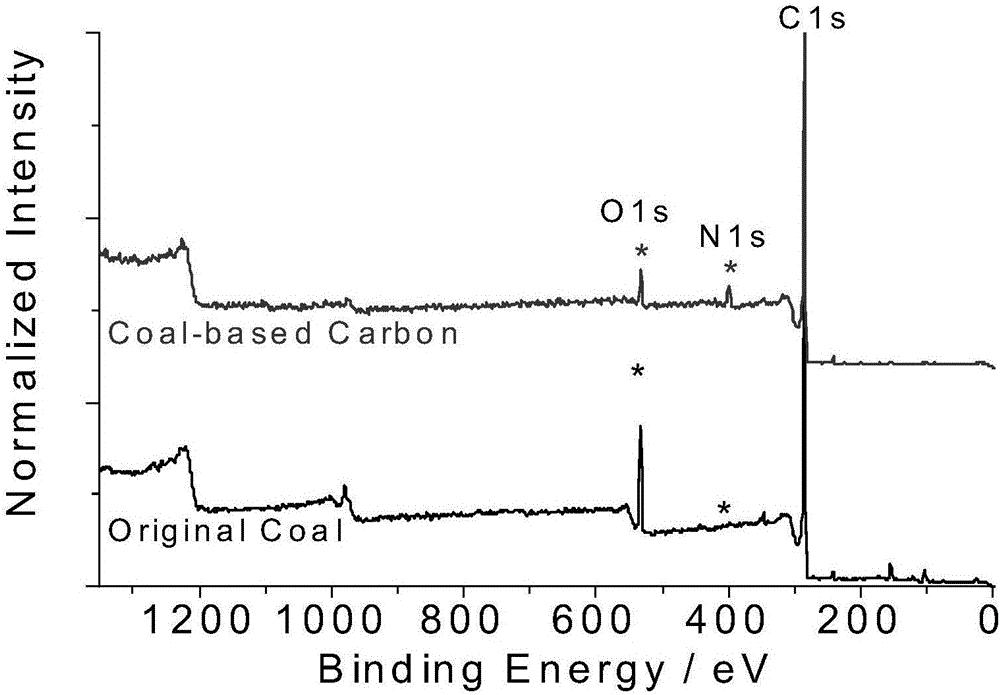

[0029] Xinjiang lignite was used as the raw material (see figure 1 ), ground in an agate mortar for 5-10 minutes to crush it to more than 200 meshes, and calcined at 800°C for 2 hours in a mixed atmosphere of ammonia and argon (volume ratio of 1:9), and the reactor was After naturally cooling to room temperature under the protection of argon, the sample was taken out to obtain the coal-based self-doped oxygen reaction electrocatalytic material. The XRD results show that the oxygen-reactive electrocatalytic material prepared by high-temperature heat treatment in an ammonia environment contains a higher graphite structure than the original coal, see figure 2 , the lower line represents the original coal sample, and the upper line is the coal-based oxygen-reactive electrocatalytic material after direct high-temperature treatment in the ammonia environment; XPS results show that after the high-temperature heat treatment process in the ammonia environment, the oxygen-reactive elec...

Embodiment 2

[0031] Using Inner Mongolia lignite as raw material, EDX elemental analysis see Figure 4 , Grinding in an agate mortar for 5-10 minutes to obtain particles above 200 meshes, calcined at 700°C for 3 hours in an atmosphere of ammonia and argon (volume ratio: 2:8), and the reactor was protected by argon After naturally cooling to room temperature, the sample was taken out to obtain the coal-based self-doped oxygen reaction electrocatalytic material. The XRD results show that the oxygen-reactive electrocatalytic material prepared by high-temperature heat treatment in an ammonia environment has a higher graphite structure than the original coal; the electrochemical test results show that the oxygen-reactive electrocatalytic material has a good oxygen reduction onset voltage and activity and optional, see Figure 5 , the upper curve is the original coal sample, and the lower curve is the coal-based oxygen reaction electrocatalytic material after direct high temperature treatment i...

Embodiment 3

[0033] Shanxi anthracite is used as raw material, ground in an agate mortar for 5-10 minutes to obtain particles with a particle size of 200 mesh or more, and calcined at 900°C for 2 After hours, the reactor was naturally cooled to room temperature under the protection of inert argon, and the sample was taken out to obtain the coal-based self-doping oxygen reaction electrocatalytic material. The results of electrochemical tests show that the oxygen-reactive electrocatalytic material has a good initial voltage and activity of water decomposing oxygen, see Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com