Preparation method of metal-organic framework-coated ptni/ionic liquid/graphene material

A metal-organic framework and ionic liquid technology, applied in the direction of material electrochemical variables, fuel cells, and final product manufacturing, can solve the problems of easy irreversible agglomeration of graphene, limited use of metal catalyst carriers, and low catalyst poisoning resistance. Achieve the effects of outstanding electrocatalytic performance, good selectivity and sensitivity, and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

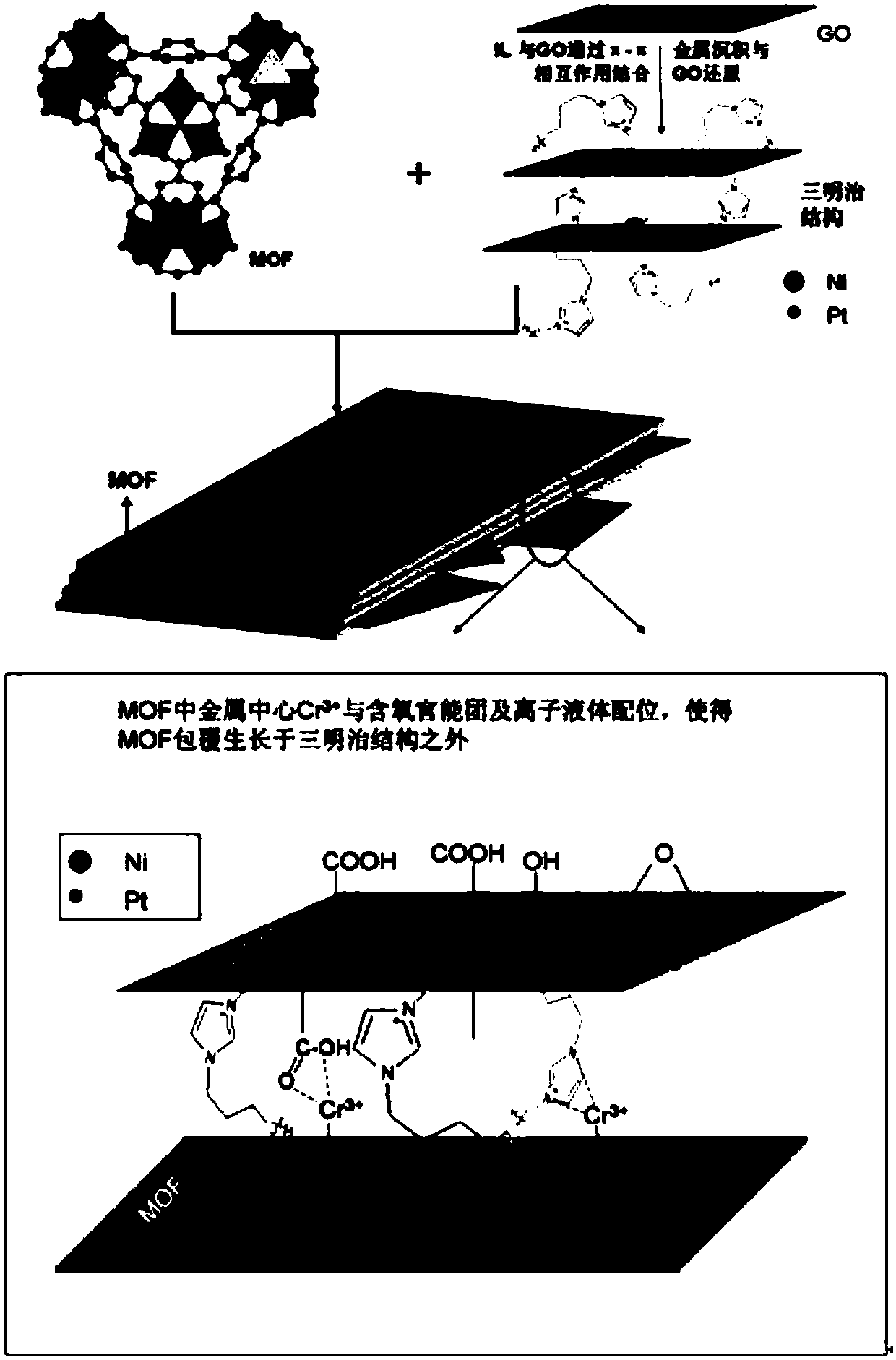

[0032] (1) PtNi / IL with sandwich structure 1 -IL 2 Preparation of / GN complex

[0033] Take 50mg graphene oxide and disperse it in 30mL methanol-water solution, sonicate for 30min. Then add 50mg ([bmim][BF 4 ]-[bmim][PF 6 ]) ionic liquid (IL) mixed solution (stirred and mixed evenly before adding), ultrasonicated for 60min to form GO-IL solution.

[0034] Take 10mL GO-IL solution, under the condition of stirring, slowly add 2mL mixed solution of chloroplatinic acid and nickel nitrate (n(Pt):n(Ni)=1:1), wherein the mol of chloroplatinic acid and nickel nitrate The concentrations were 0.076M and 0.1M, respectively. Then dropwise add 0.5M NaOH solution to adjust the pH of the solution to 10, slowly add 40mg NaBH under stirring 4 , Stir at room temperature for 24h.

[0035] Another 5 mL of GO-IL solution was slowly added to the above solution under stirring, and mixed evenly by ultrasonic. Add 0.5M NaOH solution dropwise again to adjust the pH of the solution to 10, slowly...

Embodiment 2

[0044] (1) PtNi / IL with sandwich structure 1 -IL 2 Preparation of / GN complex

[0045] Take 50mg graphene oxide and disperse it in 40mL methanol-water solution, sonicate for 30min. Then add 50mg ([bmim][BF 4 ]-[bmim][PF 6 ]) ionic liquid (IL) mixed solution (stirred and mixed evenly before adding), ultrasonicated for 60min to form GO-IL solution.

[0046] Take 20mL GO-IL solution, under stirring, slowly add 4mL mixed solution of chloroplatinic acid and nickel nitrate (n(Pt):n(Ni)=1:2), wherein the moles of chloroplatinic acid and nickel nitrate The concentrations were 0.076M and 0.1M, respectively. Then dropwise add 0.5M NaOH solution to adjust the pH of the solution to 10, slowly add 80mg NaBH under stirring 4 , Stir at room temperature for 24h.

[0047] Another 10mL GO-IL solution was slowly added to the above solution under stirring, and mixed evenly by ultrasonic. Add 0.5M NaOH solution dropwise again to adjust the pH of the solution to 10, slowly add 40mg NaBH und...

Embodiment 3

[0056] (1) PtNi / IL with sandwich structure 1 -IL 2 Preparation of / GN complex

[0057] Take 50 mg of graphene oxide and disperse it in 35 mL of methanol-water solution, sonicate for 30 min. Then add 50mg ([bmim][BF 4 ]-[bmim][PF 6 ]) ionic liquid (IL) mixed solution (stirred and mixed evenly before adding), ultrasonicated for 60min to form GO-IL solution.

[0058]Take 15mL of GO-IL solution, and slowly add 3mL of the mixed solution of chloroplatinic acid and nickel nitrate (n(Pt):n(Ni)=1:0.5) while stirring, wherein the molar amount of chloroplatinic acid and nickel nitrate The concentrations were 0.076M and 0.1M, respectively. Then dropwise add 0.5M NaOH solution to adjust the pH of the solution to 10, slowly add 60mg NaBH under stirring 4 , Stir at room temperature for 24h.

[0059] Another 7.5mL GO-IL solution was slowly added to the above solution under stirring, and mixed evenly by ultrasonic. Add 0.5M NaOH solution dropwise again to adjust the pH of the solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com