Semiconductor substrate and semiconductor element

一种半导体、基板的技术,应用在半导体器件、半导体/固态器件制造、电气元件等方向,能够解决劣化、浓度充分下降、电流坍塌再现性等问题,达到提高结晶性、抑制电流坍塌的发生、降低漏泄电流的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

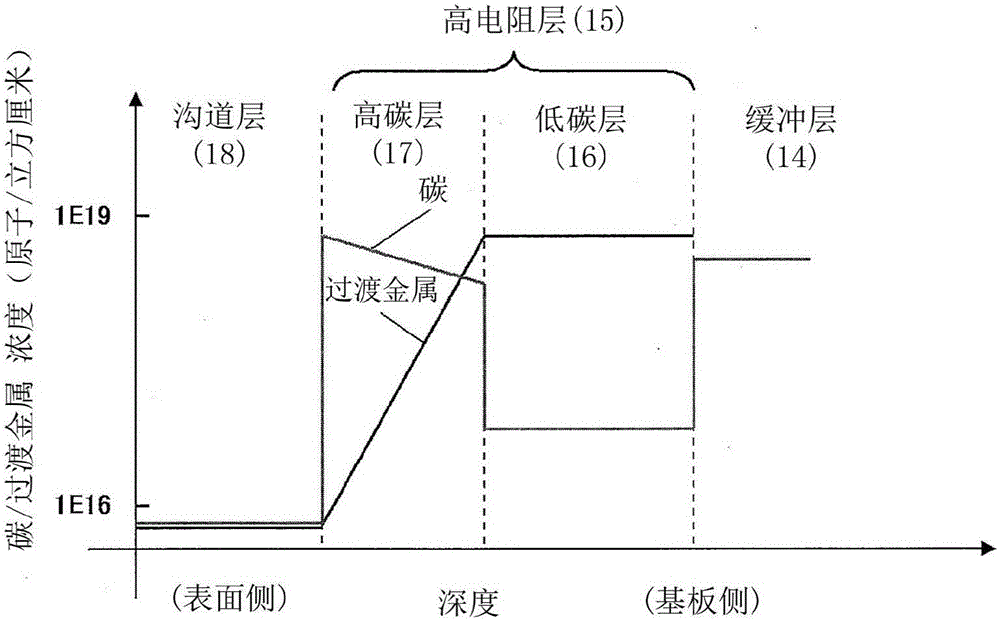

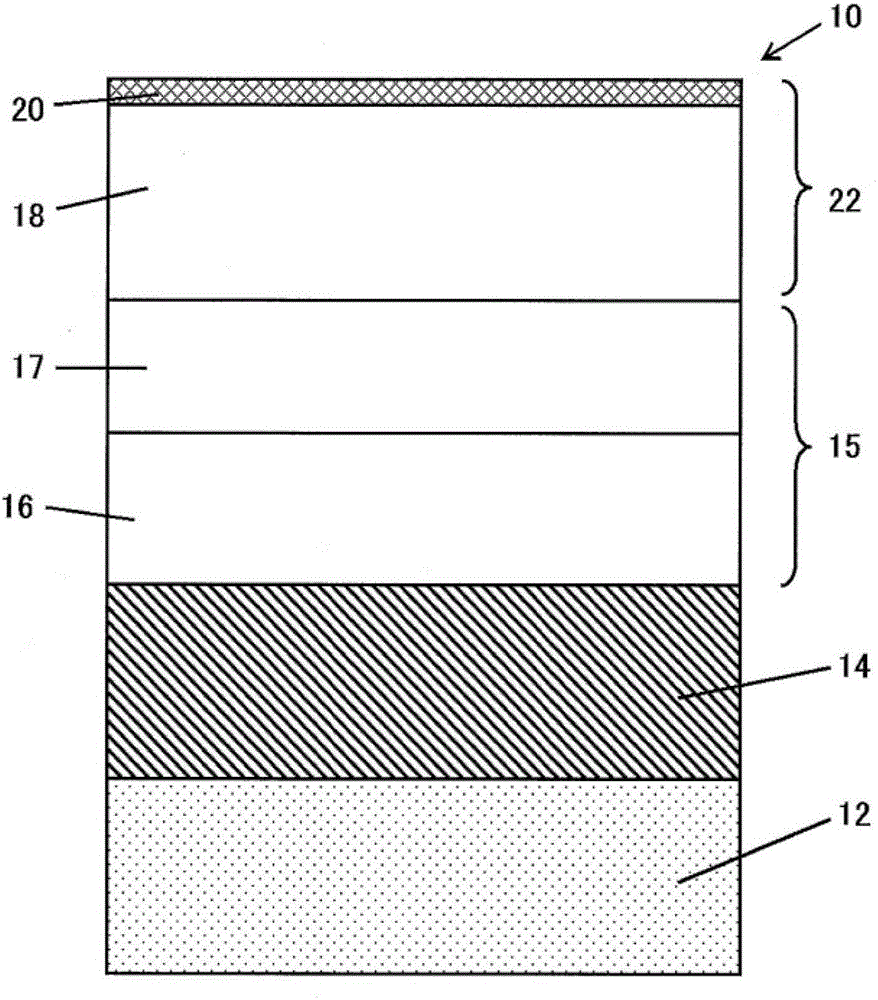

[0087] make figure 2 The semiconductor substrate shown, the semiconductor substrate has figure 1 The concentration distribution in the depth direction is shown. However, using Fe as the transition metal, the carbon concentration in the low carbon layer 16 is set to 5×10 17 Atoms / cm3, the carbon concentration in the high carbon layer 17 is set to 2×10 18 Atoms / cm3, the concentration of Fe in the low carbon layer 16 is set to 3×10 18 atoms / cubic centimeter. In addition, the thickness of the low carbon layer 16 was set to 500 nm, and the thickness of the high carbon layer was set to 1600 nm.

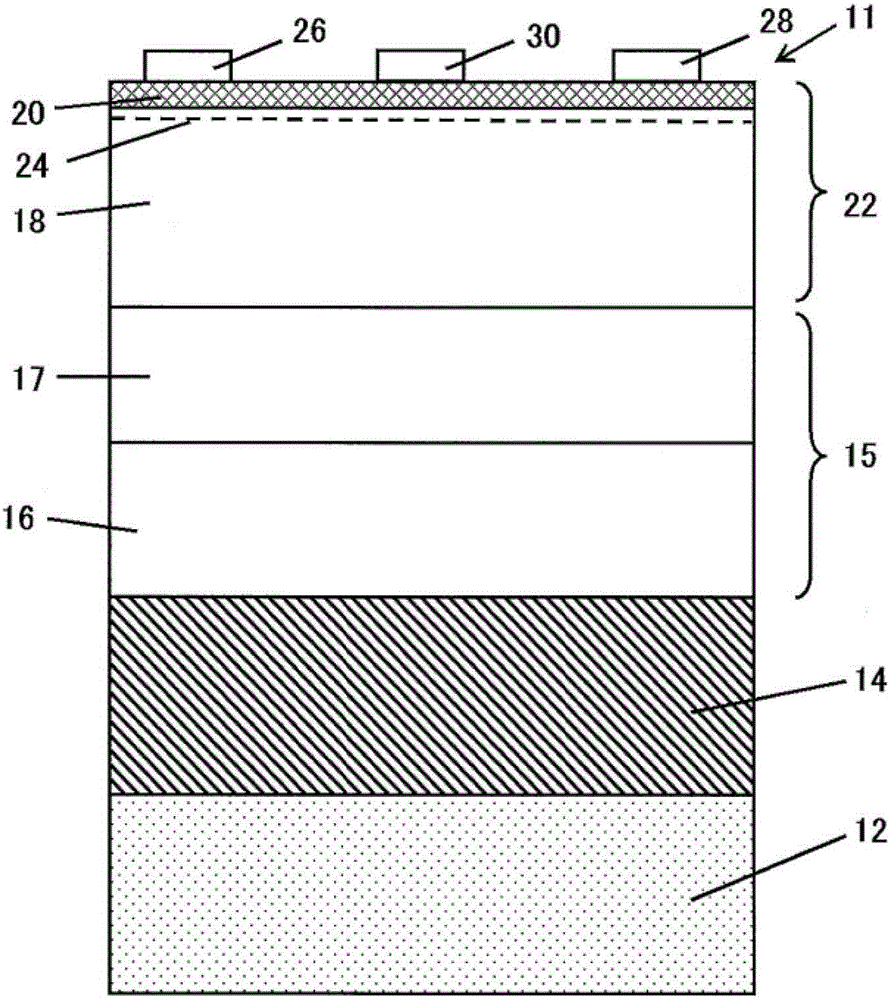

[0088] Using the fabricated semiconductor substrates, such as image 3 semiconductor components shown.

Embodiment 2

[0090] make figure 2 The semiconductor substrate shown, the semiconductor substrate has Figure 4 The concentration distribution in the depth direction is shown. However, the transition metal was not added to the high-resistance layer 15, and the carbon concentration in the low-carbon layer 16 was set to 3×10 17 Atoms / cm3, the carbon concentration in the high carbon layer 17 is set to 2×10 18 atoms / cubic centimeter. In addition, the thickness of the low carbon layer 16 was set to 100 nm, and the thickness of the high carbon layer was set to 1600 nm.

[0091] Using the fabricated semiconductor substrates, such as image 3 semiconductor components shown.

Embodiment 3

[0093] A semiconductor substrate was produced in the same manner as in Example 2. However, the thickness of the low carbon layer 16 was set to 200 nm, and the thickness of the high carbon layer 17 was set to 1500 nm.

[0094]The crystallinity of the GaN layer (including the high carbon layer 17 ) in the 0002 direction on the low carbon layer 16 was measured using X-ray diffraction for the fabricated semiconductor substrate. display the results in Figure 8 middle.

[0095] Using the fabricated semiconductor substrates, such as image 3 semiconductor components shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com