Absorbent used for removing acid gas and having oxidative degradation resistance performance

An acid gas and absorbent technology, which is applied in the field of absorbents with anti-oxidative degradation properties to achieve the effects of improving stability, improving regeneration effect, and reducing regeneration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

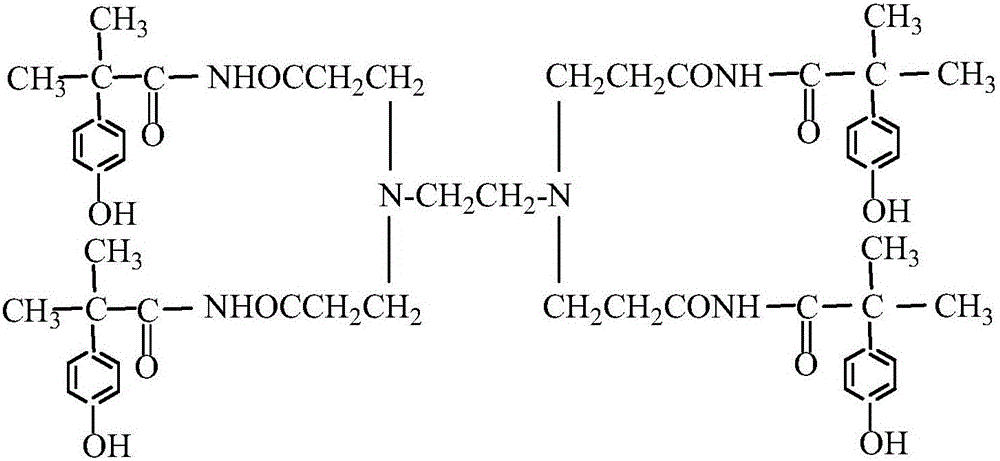

[0025] Carried out the experiment under the same conditions as Comparative Example 1, just added 0.1g antioxidant A in the above-mentioned transpolar absorbent 1#, and its antioxidant A was 2-methyl-2-p-hydroxyphenylpropionyl chloride The product reacted with 1.0G polyamide-amine is shown in the following formula. Record the initial degradation time, and the results are shown in Table 1.

[0026]

Embodiment 2

[0028] Under the same conditions as Comparative Example 1, the experiment was carried out, except that 0.05g of antioxidant A was added to the above-mentioned polarity-changing absorbent 1#, and its antioxidant A was 2-methyl-2-p-hydroxyphenylpropionyl chloride Product of reaction with 1.0G polyamidoamine. Record the initial degradation time, and the results are shown in Table 1.

Embodiment 3

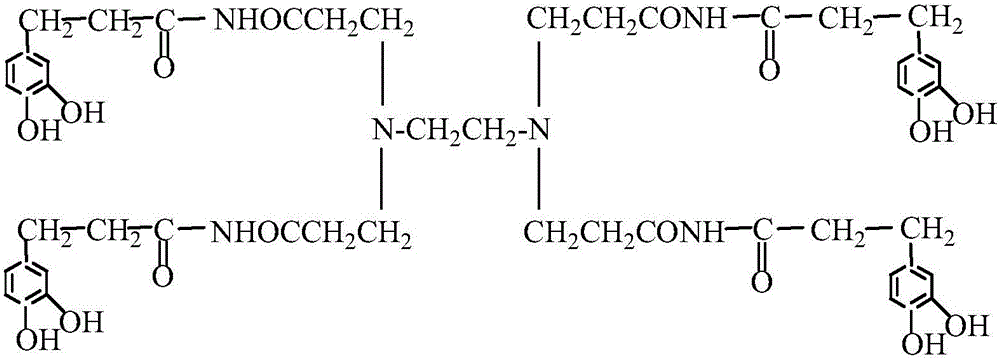

[0030] The experiment was carried out under the same conditions as in Comparative Example 1, except that 0.1 g of antioxidant B was added to the above-mentioned polarity-changing absorbent 1#, and its antioxidant B was 3,4-dihydroxyphenylpropionyl chloride and 1.0 g The product of the polyamide-amine reaction is shown in the following formula. Record the initial degradation time, and the results are shown in Table 1.

[0031]

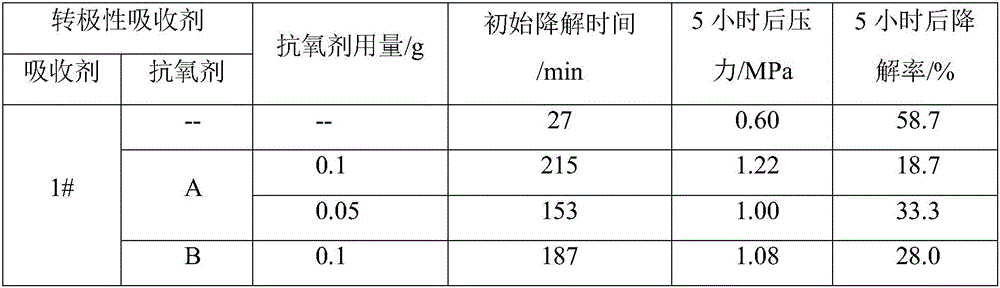

[0032] The enhanced oxidative degradation experiment result of table 1 transpolar absorbent

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com