Method for high efficiency preparation of carbon quantum dots by using biomass soot

A technology of carbon quantum dots and biomass, which is applied in the field of efficient preparation of carbon quantum dots, can solve the problems of lack of cheap preparation methods for long-wave emission carbon quantum dots, and achieve the effect of simple and feasible preparation methods, small average particle size and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

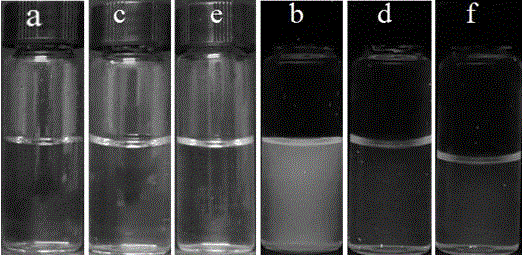

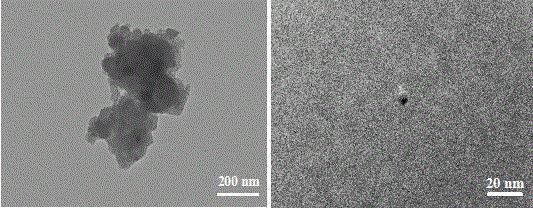

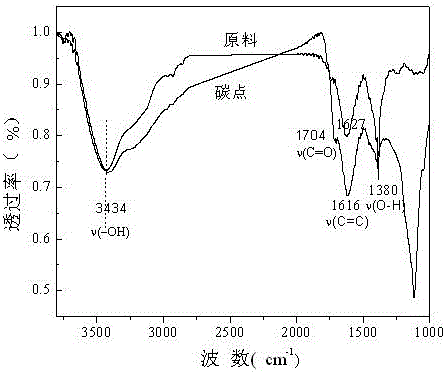

Embodiment 1

[0026] Take 50 mg of flue ash from a rural dwelling in Hebei Province in a 50 mL round-bottomed flask, put it into a beaker filled with ice water, slowly add 4 mL of concentrated sulfuric acid into the round-bottomed flask while stirring, and add the acid dropwise After that, continue stirring for 30 min. Stop stirring, sonicate for 2 h, place the round bottom flask in an oil bath, and heat at 100 °C for 24 h. After the sample was naturally cooled to room temperature, it was placed in ice water again, and 25 mL of deionized water was slowly added dropwise under stirring, and K 2 CO 3 Neutralize to pH ≈ 7, centrifuge (12,500 rpm, 30 min), remove the precipitate, transfer the supernatant to a 100 Da dialysis bag, dialyze for 3 to 6 days, discard the dialysate, and transfer the liquid in the bag to 500 Da In the dialysis bag, continue dialysis for 3 to 6 days, retain and concentrate the dialysate, then transfer the liquid in the bag to 1000 Da and 2000 Da dialysis bags in turn,...

Embodiment 2

[0028] On the basis of Example 1, the volume ratio of concentrated nitric acid to concentrated sulfuric acid was adjusted to 1:1 (the total volume was 4 mL), and other conditions remained unchanged.

Embodiment 3

[0030] On the basis of Example 2, the volume ratio of concentrated nitric acid to concentrated sulfuric acid was adjusted to 1:2, and other conditions remained unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com