Coal pyrolysis sewage treatment system and treatment method

A coal pyrolysis and sewage technology, which is applied in the field of coal pyrolysis sewage treatment system, can solve the problems of single application limitation of biological treatment method, high treatment cost and high equipment requirements, and achieve the effect of realizing resource utilization and reducing operation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

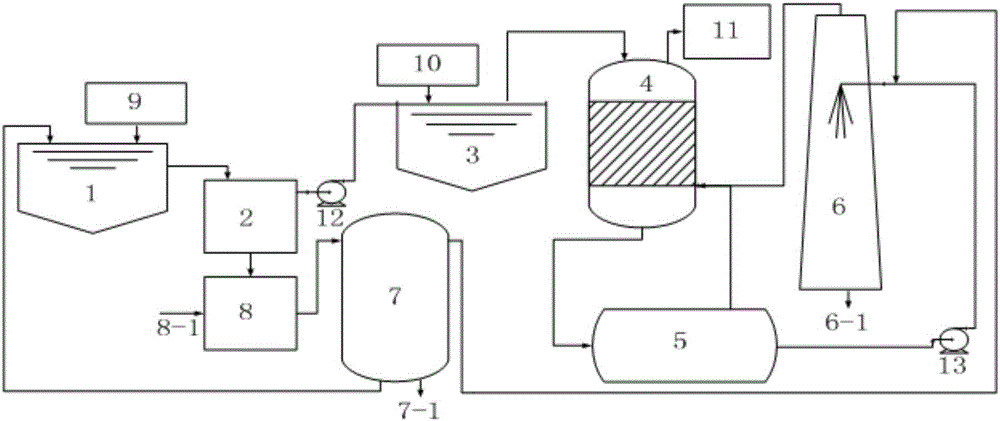

[0083] This embodiment provides a system for treating low-rank coal pyrolysis sewage, and its structural diagram is as follows figure 1 shown. Specifically include: buffer adjustment tank 1, grease trap 2, acid-base adjustment tank 3, steam stripper 4, evaporation concentration tank 5, steam boiler 6, pyrolysis furnace 7, mixer 8, dosing machine 9, dosing Machine 10, ammonia storage tank 11, water pump 12 and high-pressure water pump 13.

[0084] The buffer regulating tank 1 is provided with a sewage inlet, an acid-base regulating liquid inlet and a sewage outlet, and the sewage outlet is arranged at the bottom of the buffer regulating tank 1 . The buffer adjustment tank 1 is equipped with a dosing machine 9 and a submersible mixer, and the dosing machine 9 is connected to the inlet of the acid-base adjustment solution of the buffer adjustment tank 1 .

[0085] The grease trap 2 is provided with a pyrolysis sewage inlet, a degreasing sewage outlet and an oil sludge outlet. T...

Embodiment 2

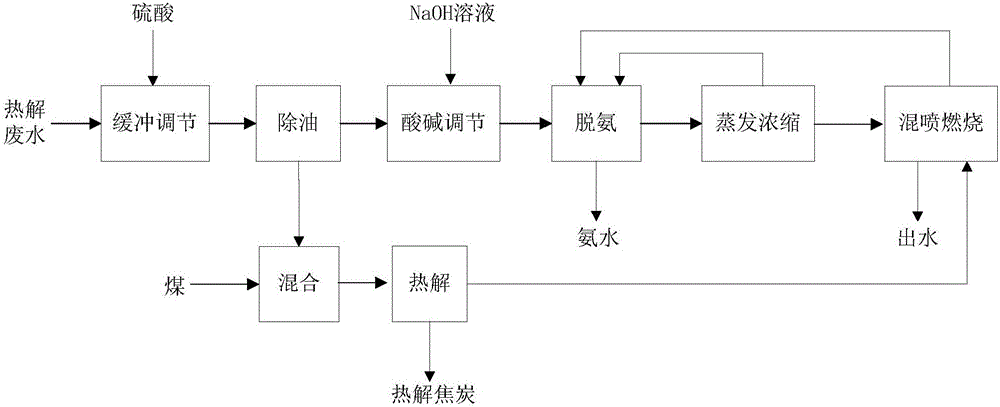

[0093] This embodiment provides a method for treating sewage from coal pyrolysis using the system provided in Embodiment 1. Specific process such as figure 2 shown.

[0094] The water quality of the coal pyrolysis sewage that present embodiment adopts is as follows:

[0095] COD=16600mg / L, BOD=6700mg / L, ammonia nitrogen=1700mg / L, volatile phenol=10000mg / L, pH=9.6.

[0096] After the sewage is discharged from the coal pyrolysis system, it enters the buffer adjustment tank 1. The dosing machine 9 adds sulfuric acid into the water body to adjust the pH of the sewage from 9.6 to 7, and the residence time is 5 hours.

[0097] The sewage discharged from the buffer adjustment tank 1 enters the grease trap 2. The oil scraper and the oil drain tank remove the suspended oil sludge in the sewage.

[0098] The sludge discharged from the grease trap 2 is fed into the mixer 8 . The oil sludge is mixed with coal and then sent to the pyrolysis furnace 7 for pyrolysis treatment to recov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com