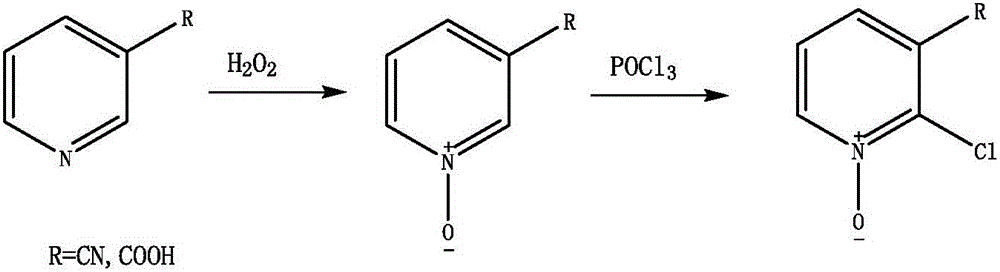

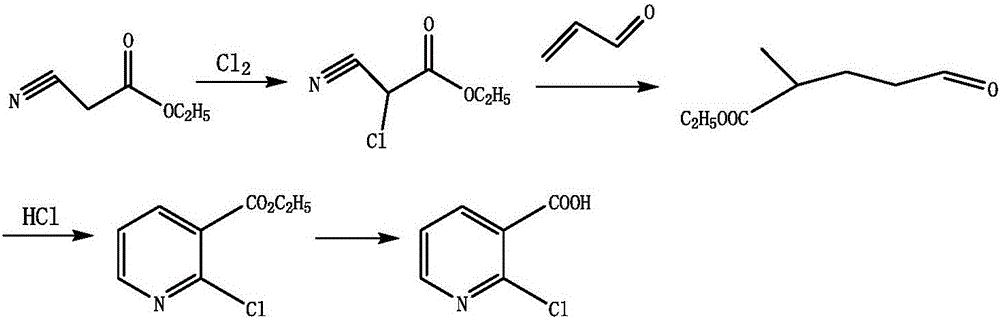

Method for one-step oxidation synthesis of 2-chloronicotinic acid

A technology of oxidative synthesis and chloronicotinic acid, which is applied in the direction of organic chemistry, can solve the problems of environmental pollution, long reaction route, and expensive oxidant, and achieve the effects of overcoming environmental pollution, easy separation, and meeting clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

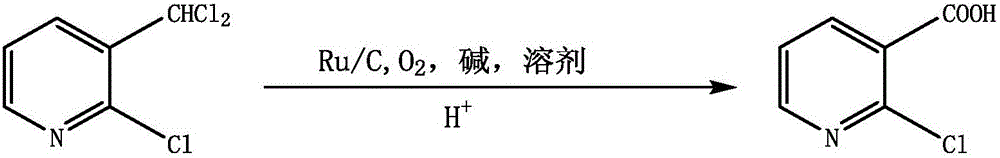

Method used

Image

Examples

Embodiment 1

[0023] 80g (0.4mol) of 2-chloro-3-dichloromethylpyridine, 40g of water, 240g of acetonitrile, 48g of sodium carbonate, 1.6g of Ru / C (10% Ru, on a dry basis), were added to a 500ml autoclave for reaction In the device, after the feeding is completed, the kettle body is replaced by oxygen, and then filled with O 2 Until the pressure of the reactor is 3MPa, the temperature is raised to 100°C, the reaction starts, the pressure of the reactor drops, and O is continuously added. 2 , maintain the reaction pressure between 3.5-4MPa, when the pressure of the kettle remains constant, the reaction ends (reaction time 12h). Lower the temperature, recover the Ru / C catalyst by suction filtration for the next application, precipitate the filtrate to recover acetonitrile, add hydrochloric acid to the remaining liquid for acid analysis (adjust the pH value of the solution to 1), a large amount of white precipitates appear, suction filter, wash, dry, 59.8 g of white solid 2-chloronicotinic aci...

Embodiment 2

[0025] It was synthesized according to the method and conditions of Example 1, only the reaction temperature was adjusted to 140° C., and the polar organic solvent was 300 g of tetrahydrofuran. The reaction time was shortened to 4 hours, and 62.4 g of white solid 2-chloronicotinic acid was obtained after post-treatment. The purity of 2-chloronicotinic acid was 96.2%, and the yield was 95.4%.

Embodiment 3

[0027] Synthesized as in the method and conditions of Example 1, only changing the oxygen pressure to 4.5-5 MPa for reaction. The reaction time was shortened to 8 hours, and 61.9 g of 2-chloronicotinic acid was obtained as a white solid after post-treatment. The purity of 2-chloronicotinic acid was 97.9%, and the yield was 96.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com