Erosion agent for Super304H austenitic stainless steel durable specimen tissue display, preparation method and application method

A technology of austenitic stainless steel and etchant, applied in the preparation of test samples, etc., to achieve the effect of easy control of erosion speed, strong reusability, and clear display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

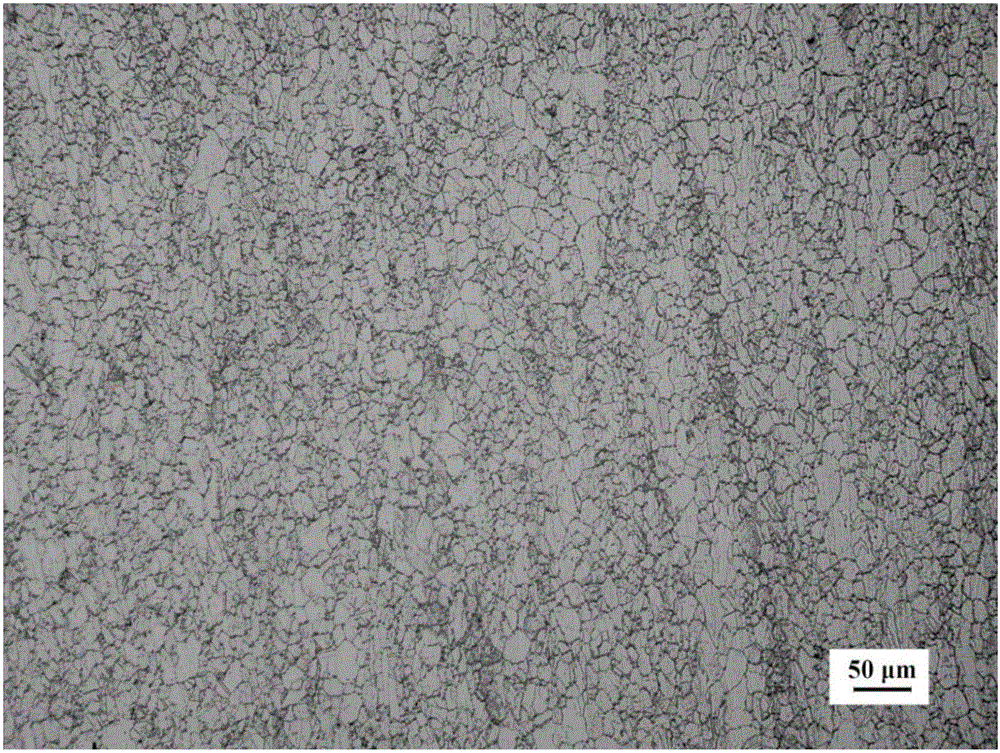

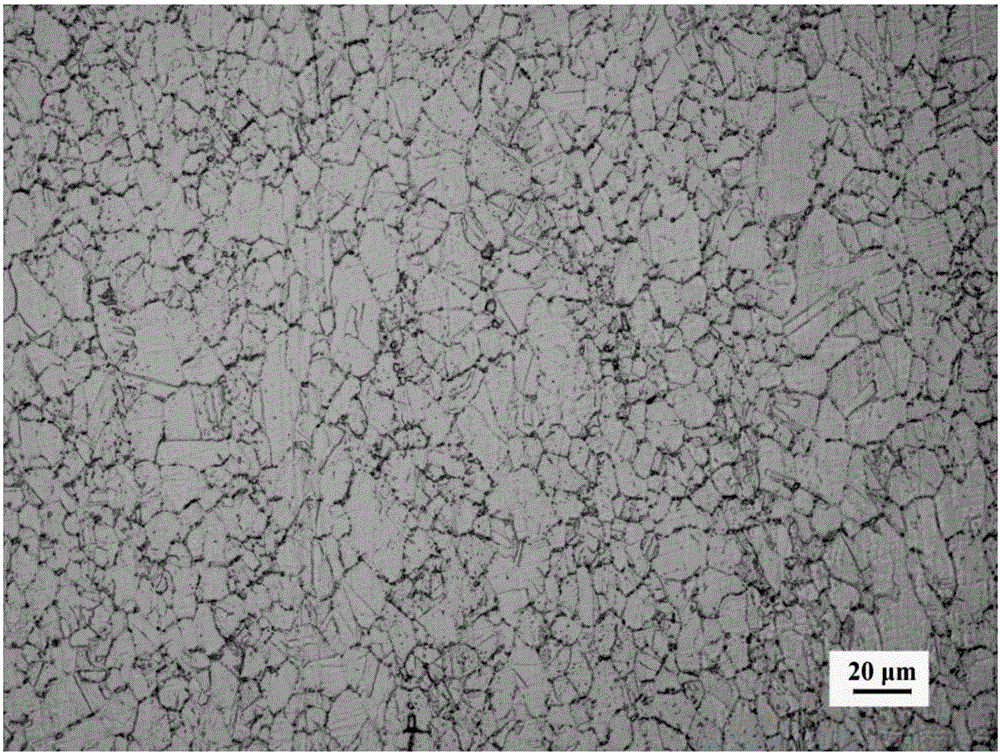

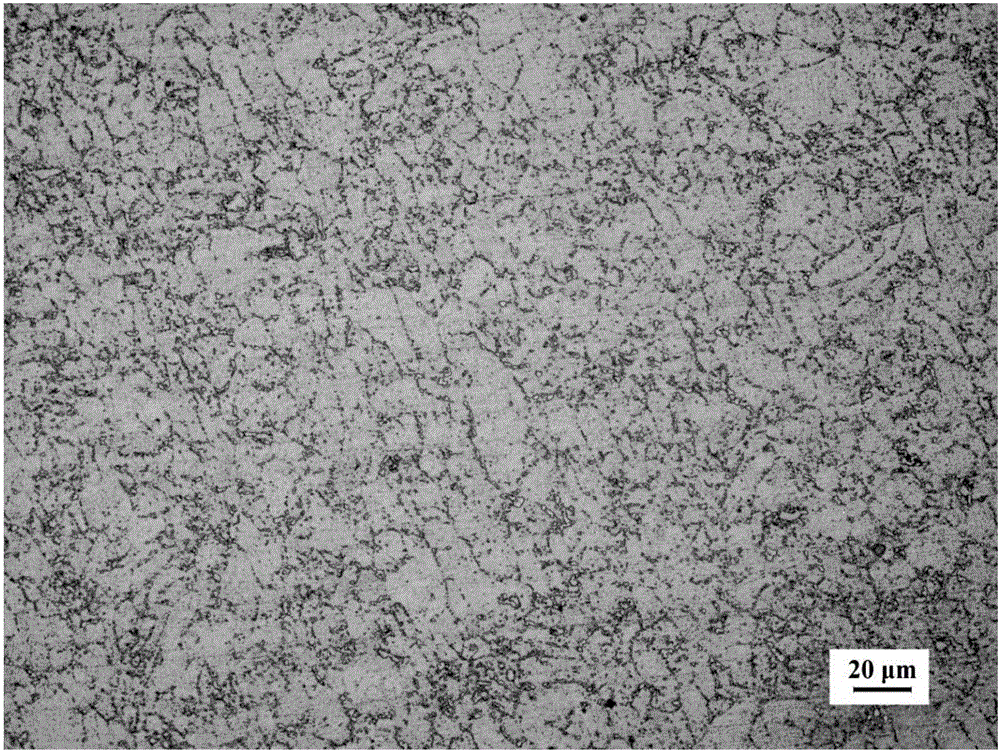

Image

Examples

Embodiment 1

[0023] Example 1: Mix 50 milliliters of distilled water and 50 milliliters of dehydrated ethanol in a beaker, measure 20 milliliters of analytically pure hydrochloric acid and 20 milliliters of analytically pure hydrofluoric acid, and slowly add them to the beaker along the inner wall of the beaker, stirring continuously. Finally, add and weigh 5 grams of ferric trichloride, stir and mix evenly to obtain the etchant.

Embodiment 2

[0024] Example 2: Mix 45 milliliters of distilled water and 56 milliliters of absolute ethanol in a beaker, measure 18 milliliters of analytically pure hydrochloric acid and 18 milliliters of analytically pure hydrofluoric acid, and slowly add them into the beaker along the inner wall of the beaker, stirring continuously. Finally, add and weigh 4.5 grams of ferric chloride, stir and mix evenly to obtain the etchant.

Embodiment 3

[0025] Example 3: Mix 45 milliliters of water and 62 milliliters of absolute ethanol in a beaker, measure 19 milliliters of analytically pure hydrochloric acid and 19 milliliters of analytically pure hydrofluoric acid, and slowly add them to the beaker along the inner wall of the beaker, stirring constantly, Finally, add and weigh 5.5 grams of ferric trichloride, stir and mix evenly to obtain the etchant.

[0026] The application method of etching agent of the present invention is as follows:

[0027] 1) Take a metallographic test block from the Super304H durable sample, grind and mechanically polish the surface, clean it with absolute ethanol, and then dry it with a hair dryer;

[0028] 2) Pour the etching agent of the present invention into a glass vessel with absorbent cotton, and immerse the metallographic test block of the polished Super304H durable sample with the erosion side facing down, and the erosion time is 1-3 minutes. When the surface of the sample is white-gray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com