Permanent waterproof layer of building roof

A waterproof layer and permanent technology, applied in the direction of roof insulation materials, etc., can solve problems such as complex construction, achieve the effect of reducing cost, high toughness, and overcoming easy cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

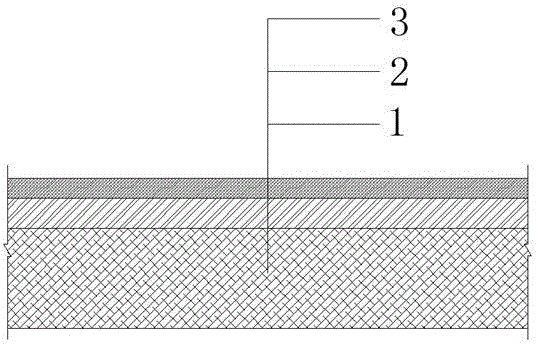

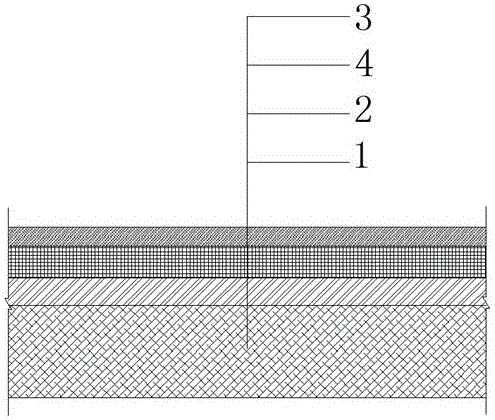

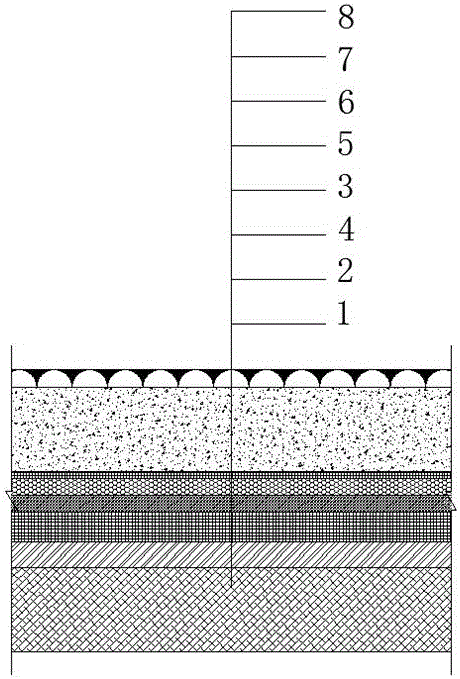

Image

Examples

Embodiment Construction

[0040] The production of the UHPC waterproof layer of the building roof can be divided into five working steps: preparation of UHPC dry mix, on-site mixing of UHPC mix, pouring and paving construction, setting of construction joints, and maintenance:

[0041] 1. Prepare UHPC dry mix in the factory: 1 part of Portland cement, 0.1-0.3 parts of silica fume, 0.1-0.3 parts of mineral admixture, 1.0-1.5 parts of graded sand, 0.003-0.02 parts of shrinkage reducer, 0.002~0.01 part of curing agent and 0.01~0.1 part of water reducing agent are put into the mixer according to the proportion, mixed evenly, and packed for use.

[0042] 2. On-site mixing of UHPC mixture: transport the UHPC dry mixture to the site. First put the UHPC dry mix into the mixer, add water and mix according to the water / glue (total of cement, silica fume and mineral admixture) ratio of 1:0.13~0.22, and add 1.5% by volume after the mixture becomes cohesive ~5% steel fiber, stir evenly and pour out of the machine. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com