Biological absorbable three-dimensional printing strontium-contained mesoporous bioactive glass support and preparation method thereof

A technology of bioglass and three-dimensional printing, applied in the field of biomedical materials, to achieve strong mechanical properties, good bone formation ability, and the effect of promoting osteogenesis ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

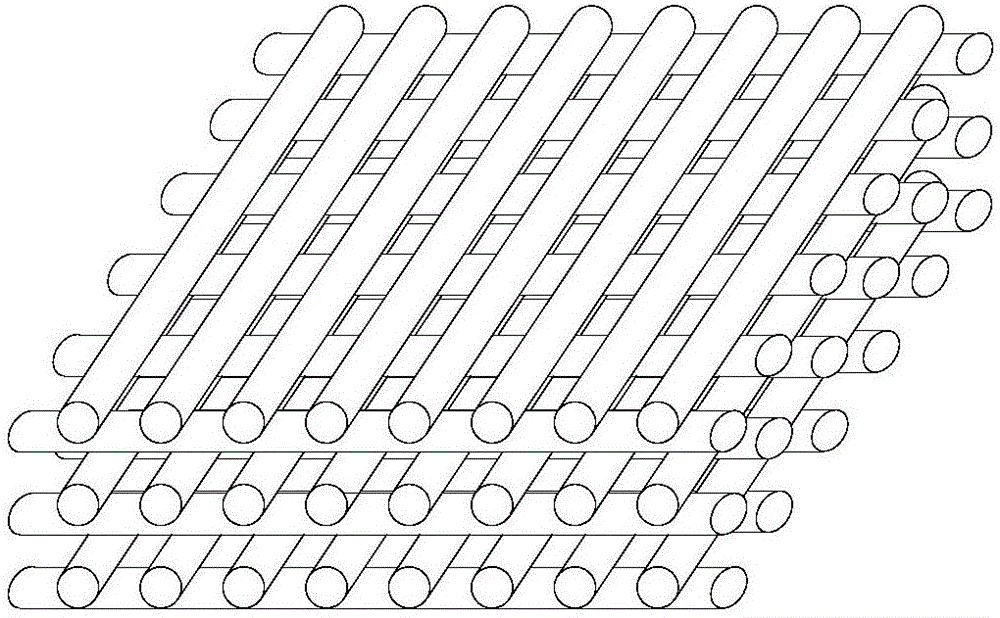

[0034] Example 1: Preparation of a bioabsorbable 3D-printed strontium-containing mesoporous bioglass scaffold

[0035] Preparation of a bioabsorbable three-dimensional printed strontium-containing mesoporous bioglass scaffold, comprising the following steps:

[0036] Step 1, preparing strontium-containing bioactive glass powder, passing through a 400-mesh sieve to make the size smaller than 37 μm, and storing it dry for later use;

[0037]For the preparation method of strontium-containing bioactive glass powder, please refer to the literature Zhang J, Zhao S, Zhu Y, et al.Three-dimensional printing of strontium-containing mesoporous bioactiveglass scaffolds for bone regeneration[J].Acta Biomaterialia,2014,10(5) :2269-2281. Preferably 5% of Sr-MBG.

[0038] Step 2, dissolving polycaprolactone (PCL, molecular weight 70,000-90,000, purchased from Sigma-Aldrich) in chloroform, magnetic stirring for 2 hours, and sealing for future use;

[0039] Step 3: Add the strontium-containin...

Embodiment 2

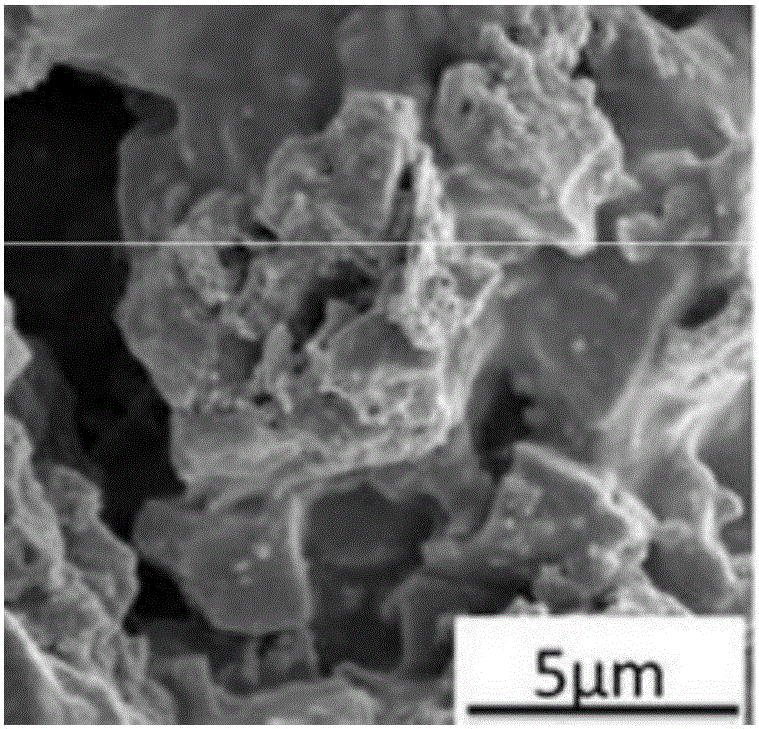

[0042] Example 2: Adhesion of MC3T3-E1 cells on bioabsorbable 3D-printed strontium-containing mesoporous bioglass scaffolds

[0043] MC3T3-E1 cells (mouse embryonic osteoblast precursor cells) were purchased from the Cell Bank of the Chinese Academy of Sciences.

[0044] Three-dimensionally printed strontium-containing mesoporous bioglass scaffold material samples were soaked in 75% medical alcohol for 4 hours, and then sterilized under ultraviolet light for 24 hours. At the same time, 1ml of α-MEM containing 10% FBS was added to the 24-well plate for culture The substrate was pre-wetted for 24 hours, the medium was replaced, and then the sterilized scaffold material was transferred into a 24-well plate. Then, will contain 1×10 5 200 μl of culture medium of MC3T3-E1 cells was added dropwise to each sample, and incubated at 37°C, 5% CO 2 Atmosphere CO 2 Cultivate in an incubator, and after 8 hours the cells basically adhere to the wall, add 1 ml of α-MEM medium containing 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com