Solvent-resistant composite nanofiltration membrane and preparing method

A composite nanofiltration membrane, solvent-resistant technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of separation performance decline, swelling, dissolution, etc., to achieve rapid reaction, simple process, high separation Effects of selectivity and solvent tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

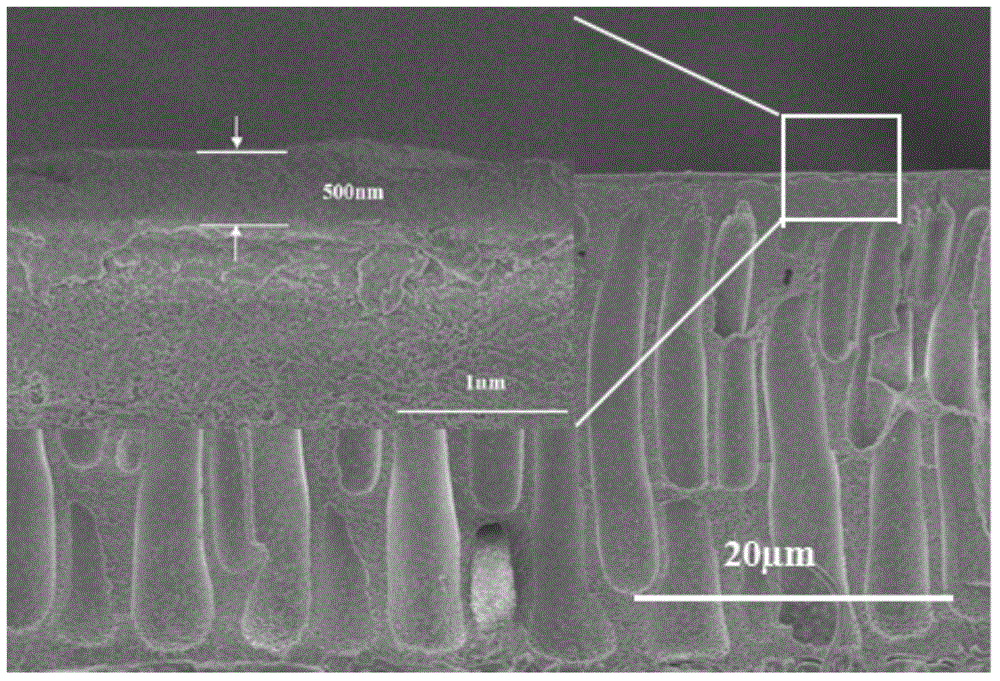

Image

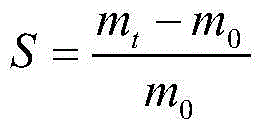

Examples

Embodiment 1

[0027] A preparation method of a solvent-resistant composite nanofiltration membrane, comprising the steps of:

[0028] (1) Mix polyetherimide and N,N-dimethylacetamide so that the mass concentration of polyetherimide-N,N-dimethylacetamide solution is 15%, at 35°C, stir 3 hours, and then at a temperature of 15°C, let it stand for defoaming for 12 hours to make a casting solution, press 600cm 2 The ratio of 12g scrapes the cast film solution on the smooth surface of a smooth non-woven fabric, places it in the air for 5 seconds, then puts it into deionized water, soaks it for 10 minutes, takes it out and blots the surface moisture with filter paper, and obtains the base For the film, the side of the scraped casting film of the non-woven fabric is called the A side;

[0029] (2) Soak the A side of the base film in an ethylenediamine methanol solution with a mass concentration of 0.1%, soak for 1 hour, take it out, wash it 3 times with deionized water, and obtain a crosslinked fi...

Embodiment 2

[0035] A preparation method of a solvent-resistant composite nanofiltration membrane, comprising the steps of:

[0036] (1) Mix polyetherimide and N,N-dimethylformamide so that the mass concentration of polyetherimide-N,N-dimethylformamide solution is 40%, stir at 80°C The time is 8 hours, and then at a temperature of 20°C, stand for degassing for 5 hours to make a casting solution, press 600cm 2 The ratio of 15g scrapes the cast film solution on the smooth surface of the non-woven fabric with a smooth surface, places it in the air for 30 seconds, then puts it into deionized water, soaks it for 40 minutes, takes out the surface moisture with filter paper, and obtains the base For the film, the side of the scraped casting film of the non-woven fabric is called the A side;

[0037] (2) Soak the A side of the base film in an ethylenediamine methanol solution with a mass concentration of 20%, soak for 1 hour, take it out, wash it 3 times with deionized water, and obtain a cross-l...

Embodiment 3

[0042] A preparation method of a solvent-resistant composite nanofiltration membrane, comprising the steps of:

[0043] (1) Mix polyetherimide and N,N-dimethylformamide so that the mass concentration of polyetherimide-N,N-dimethylformamide solution is 30%, at 35°C, stir The time is 4 hours, and then at a temperature of 6°C, stand for degassing for 24 hours to make a casting solution, press 600cm 2The ratio of 20g scrapes the cast film solution on the smooth surface of a smooth non-woven fabric, places it in the air for 60 seconds, then puts it into deionized water, soaks it for 5 minutes, takes out the surface moisture with filter paper, and obtains the base For the film, the side of the scraped casting film of the non-woven fabric is called the A side;

[0044] (2) Soak the A side of the base film in an ethylenediamine methanol solution with a mass concentration of 10%, soak for 0.5 hours, take it out, wash it twice with deionized water, and obtain a crosslinked film;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com