Magnetic nano microcapsule adsorbent and preparation method and application thereof

A magnetic nanometer and microcapsule technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of difficult separation, complicated operation, high cost, and achieve the optimization of adsorption performance and dispersion performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

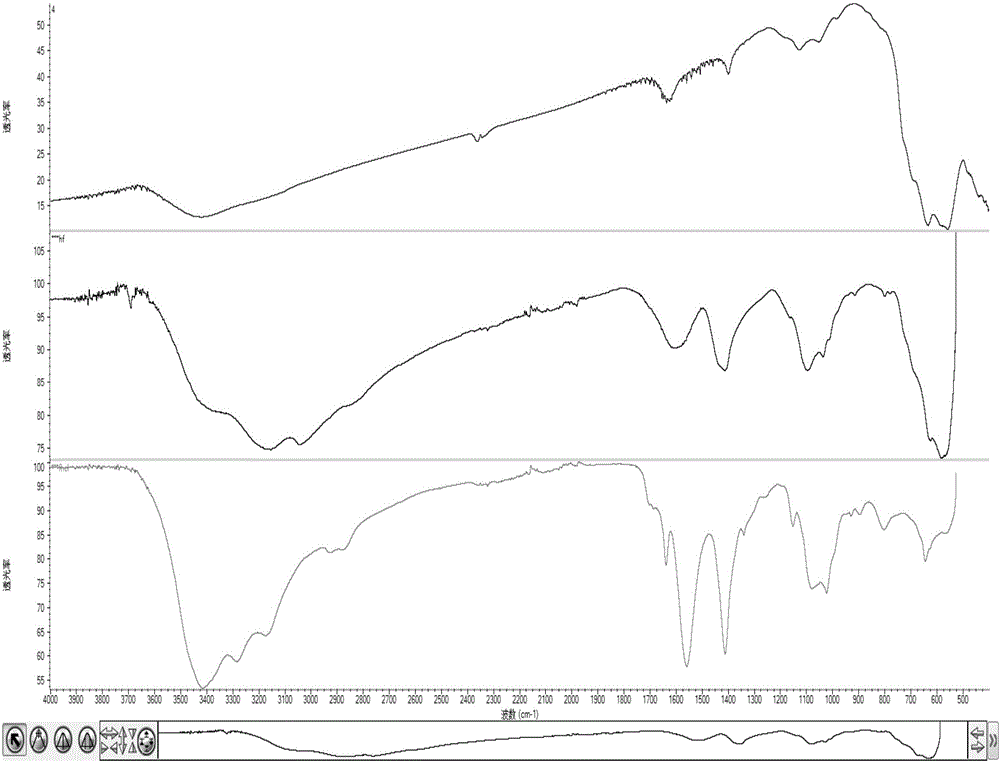

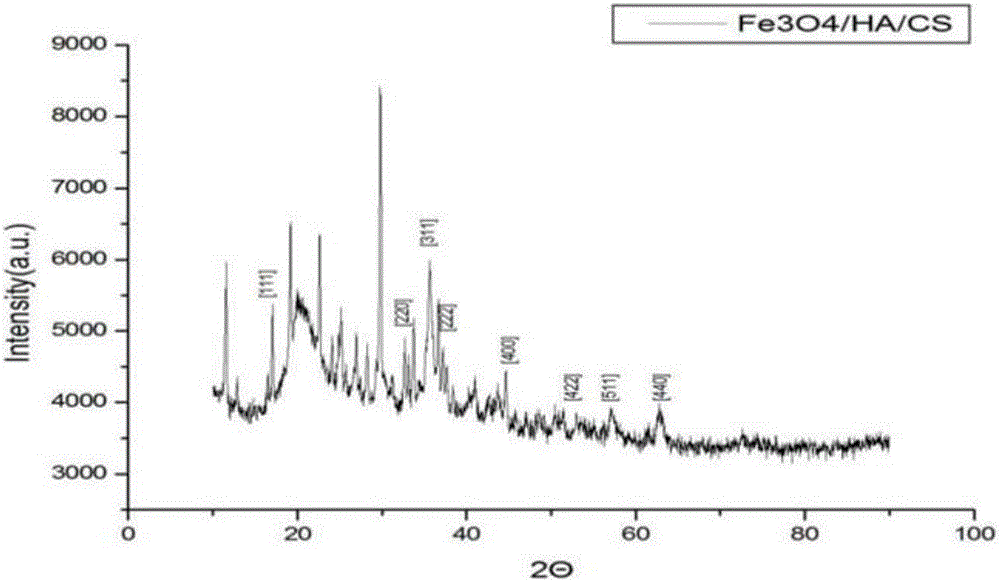

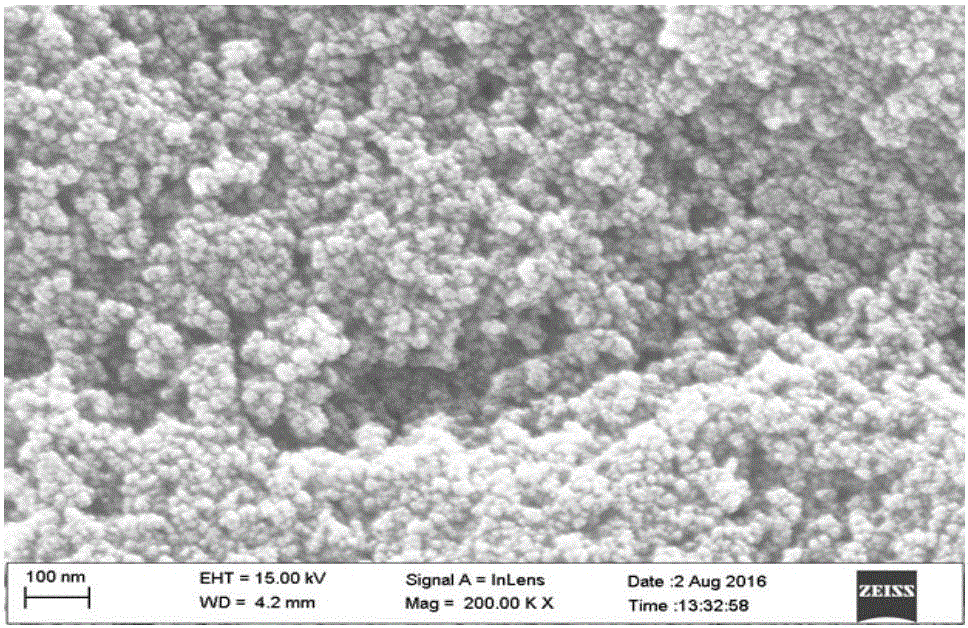

[0025] Such as Figure 1-3 Shown is a magnetic nano-microcapsule adsorbent and its preparation method and application, including nano ferric oxide, humic acid and chitosan, the ferric ferric oxide is a nano structure with a particle size of 5-20nm.

[0026] Preparation of adsorbent based on magnetic nanocapsules: 1. Use a measuring cylinder to measure 100mL deionized water into a three-necked flask, and pass nitrogen to remove oxygen, and take 6.1g FeCl 3 ·6H 2 O and 4.2 g FeSO 4 ·7H 2 O was dissolved in a three-necked flask, heated to 90°C in a water bath, and then two solutions were quickly added to the three-necked flask: 10mL of 25% ammonia solution and 50mL of 0.5g humic acid solution, and the mixed solution was placed at 90 Continue to stir at ℃ for 30 minutes, then cool to room temperature, then put it into a centrifuge tube, wash it twice with a large amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com