Polyacrylonitrile fiber-hemin biomimetic catalyst and preparation method thereof

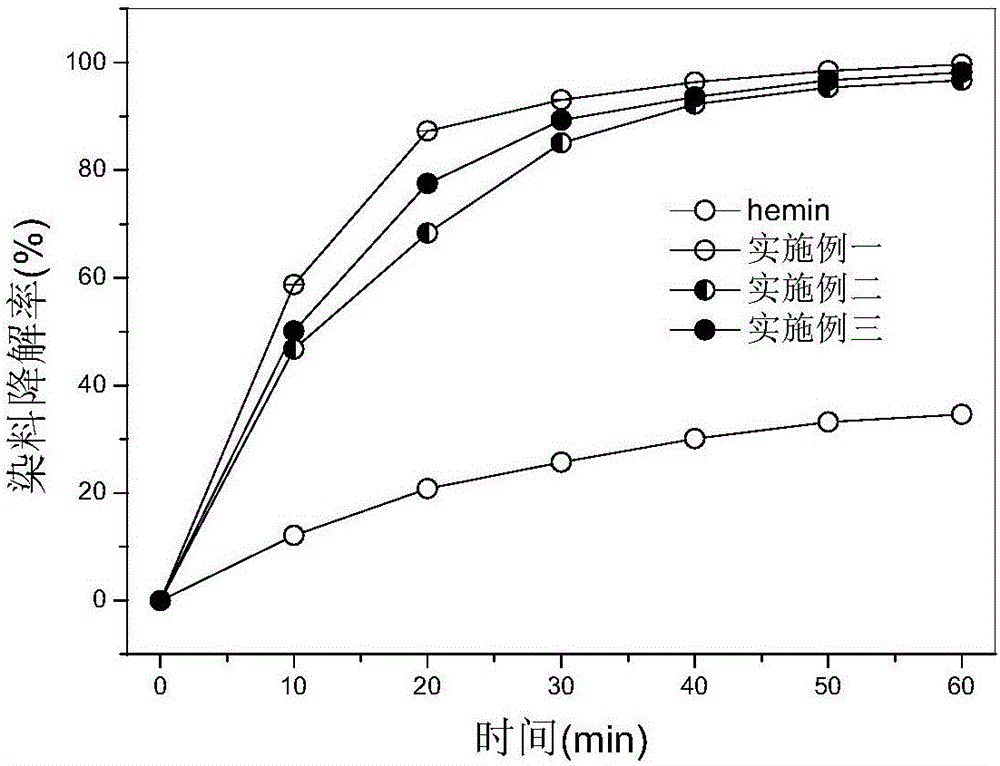

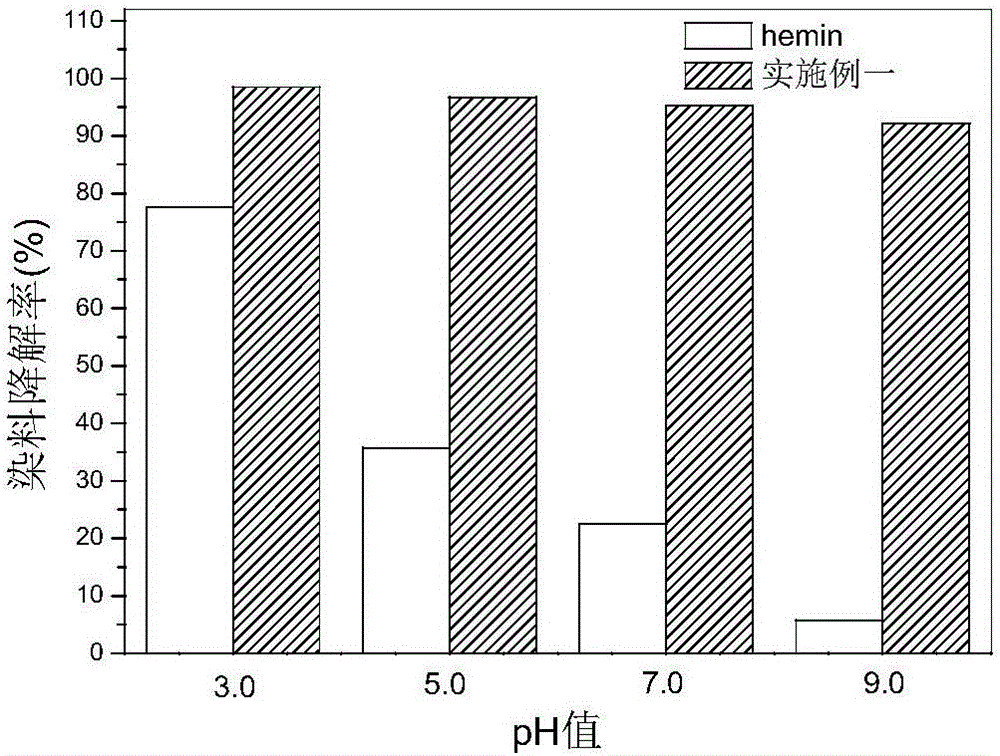

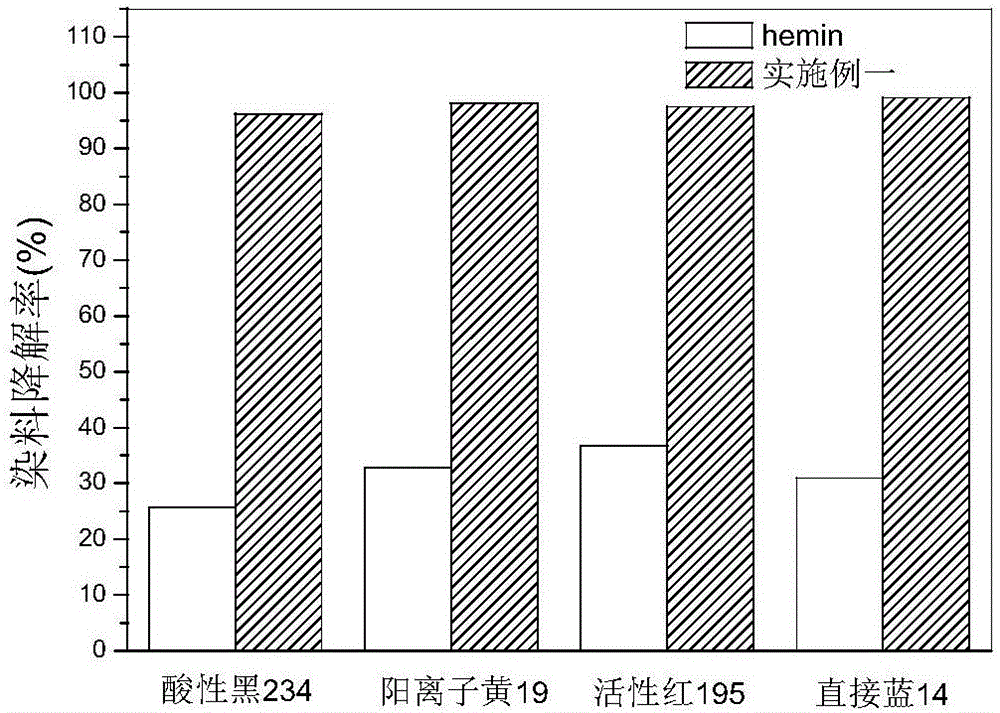

A technology of polyacrylonitrile fiber and biomimetic catalyst, applied in the field of biomimetic catalysis, can solve the problems of unsatisfactory catalytic activity, high energy consumption, complicated preparation process, etc., and achieve the effects of improving catalytic activity, low energy consumption and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention also provides a kind of polyacrylonitrile fiber-hemin biomimetic catalyst preparation method, and concrete steps are:

[0019] 1) Take polyacrylonitrile fiber and 2-aminoimidazole according to weight ratio 1: (0.83-4.165), add polyacrylonitrile fiber to 2-aminoimidazole aqueous solution, adjust pH value to 9.5 with sodium hydroxide, at 95 ° C React with stirring for 2-6 hours, then take it out and wash and dry it repeatedly with distilled water to obtain modified polyacrylonitrile fibers.

[0020] 2) Take the modified polyacrylonitrile fiber and hemin according to the weight ratio 1: (0.1-0.5), place the modified polyacrylonitrile fiber in the DMF solution of hemin, and react for 1-2.5 minutes at 40-60°C under stirring conditions After h, it was taken out, washed repeatedly with DMF and distilled water, and then dried to obtain a polyacrylonitrile fiber-hemin biomimetic catalyst.

[0021] The concentration of the 2-aminoimidazole aqueous solution ...

Embodiment 1

[0024] 1) Put accurately weighed 1.0g polyacrylonitrile fibers into 50ml of 2-aminoimidazole aqueous solution with a concentration of 83.3g / L, adjust the pH value to 9.5 with sodium hydroxide, and react at 95°C for 4h under stirring conditions, Then take it out and repeatedly wash and dry it with distilled water to obtain the modified polyacrylonitrile fiber.

[0025] 2) Weigh 1.0g of modified polyacrylonitrile fiber and place it in 100ml of hemin DMF solution with a concentration of 4.0g / L, react at 60°C for 2.5h under stirring conditions, take it out, wash it repeatedly with DMF and distilled water, and then dry it , to obtain the first polyacrylonitrile fiber-hemin biomimetic catalyst.

[0026] The nitrogen content of the modified polyacrylonitrile fiber before loading hemin was determined to be 34.5% by an elemental analyzer, so as to evaluate its imidazole ring group content. Determination of catalyst iron ion content: accurately weigh 0.1g catalyst, dissolve in V(HNO 3...

Embodiment 2

[0028] The concentration of 2-aminoimidazole in Step 1 of Example 1 was adjusted to 66.7 g / L, the concentration of hemin in Step 2 was adjusted to 2.0 g / L, and the rest was the same as in Example 1 to obtain the second polyacrylonitrile fiber-hemin biomimetic catalyst. Through measurement and calculation, the nitrogen content in the fiber carrier material is 30.1%, and the iron ion content of the catalyst is 10.2 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com