Laser welding method for thin-walled tantalum tube and thin-walled iron-nickel alloy pipe

An iron-nickel alloy and laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of iron-nickel alloys with different melting points, easy deformation, and low-melting iron-nickel alloy burning. The effect of high strength and high reliability connection, tight joint connection and narrow heat affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

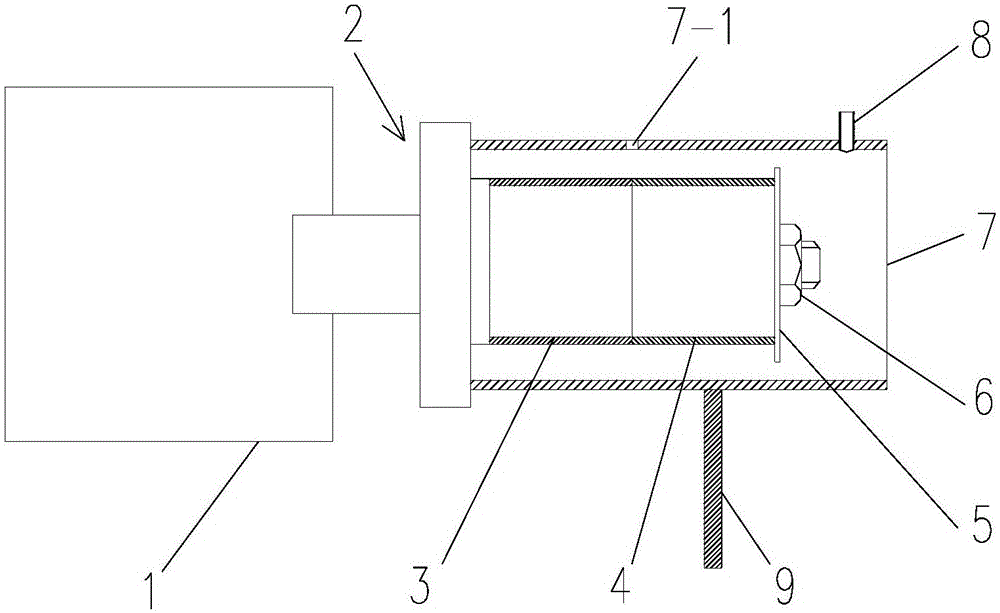

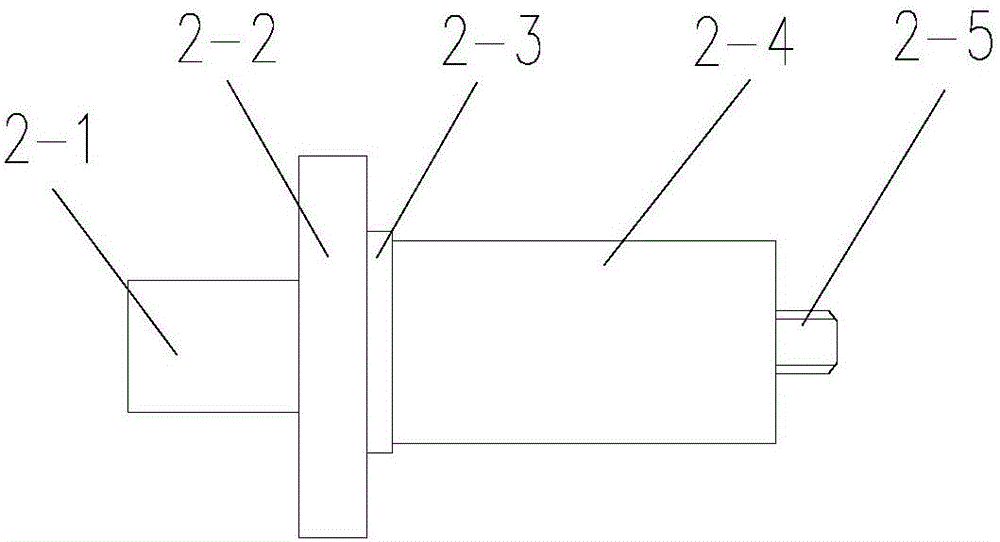

[0032] combine figure 1 and figure 2 , the laser welding method of the thin-walled tantalum tube and the thin-walled iron-nickel alloy tube in this embodiment comprises the following steps:

[0033] Step 1. Cleaning before welding: remove the burrs of the thin-walled tantalum tube 3 and the thin-walled iron-nickel alloy tube 4 under a microscope, and then perform welding on the thin-walled tantalum tube 3 and the thin-walled iron-nickel alloy tube 4 after deburring Carry out grinding and polishing, and then place the ground and polished thin-walled tantalum tube 3 and thin-walled iron-nickel alloy tube 4 in absolute ethanol for ultrasonic cleaning, the temperature of ultrasonic cleaning is 60°C, and the time of ultrasonic cleaning is 30 minutes; The outer diameters and wall thicknesses of the thin-walled tantalum tube 3 and the thin-walled iron-nickel alloy tube 4 are equal; Both are 60mm; the coaxiality tolerance of the thin-walled tantalum tube 3 and the thin-walled iron-...

Embodiment 2

[0038] combine figure 1 and figure 2 , the laser welding method of the thin-walled tantalum tube and the thin-walled iron-nickel alloy tube in this embodiment comprises the following steps:

[0039]Step 1. Cleaning before welding: remove the burrs of the thin-walled tantalum tube 3 and the thin-walled iron-nickel alloy tube 4 under a microscope, and then perform welding on the thin-walled tantalum tube 3 and the thin-walled iron-nickel alloy tube 4 after deburring Carry out grinding and polishing, and then place the ground and polished thin-walled tantalum tube 3 and thin-walled iron-nickel alloy tube 4 in absolute ethanol for ultrasonic cleaning, the temperature of ultrasonic cleaning is 60°C, and the time of ultrasonic cleaning is 30 minutes; The outer diameters and wall thicknesses of the thin-walled tantalum tube 3 and the thin-walled iron-nickel alloy tube 4 are equal; Both are 80mm; the coaxiality tolerance of the thin-walled tantalum tube 3 and the thin-walled iron-n...

Embodiment 3

[0044] combine figure 1 and figure 2 , the laser welding method of the thin-walled tantalum tube and the thin-walled iron-nickel alloy tube in this embodiment comprises the following steps:

[0045] Step 1. Cleaning before welding: remove the burrs of the thin-walled tantalum tube 3 and the thin-walled iron-nickel alloy tube 4 under a microscope, and then perform welding on the thin-walled tantalum tube 3 and the thin-walled iron-nickel alloy tube 4 after deburring Carry out grinding and polishing, and then place the ground and polished thin-walled tantalum tube 3 and thin-walled iron-nickel alloy tube 4 in absolute ethanol for ultrasonic cleaning, the temperature of ultrasonic cleaning is 60°C, and the time of ultrasonic cleaning is 30 minutes; The outer diameters and wall thicknesses of the thin-walled tantalum tube 3 and the thin-walled iron-nickel alloy tube 4 are equal; Both are 100mm; the coaxiality tolerance of the thin-walled tantalum tube 3 and the thin-walled iron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com