A micro-nano array structure, preparation method and application

A technology of array structure and nanostructure, which is applied in the field of micro-nano array structure and preparation, can solve the problems of inability to achieve broad-spectrum absorption, practical application obstacles, and difficulty in rapid processing, etc., to achieve infrared wide-spectrum absorption and large-area rapid The effect of processing and processing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation of the micro-nano array structure includes the following steps:

[0054] (1) Spin-coat a 2-μm-thick UV photoresist on a 330-μm-thick silicon carbide substrate, bake for 5 minutes after spin-coating, and then use a UV lithography machine to expose for 40 seconds, then develop in a developer for 40 seconds;

[0055] (2) After plating 400nm copper with an electron beam evaporation coating instrument, put it in acetone to remove glue;

[0056] (3) Using reactive ion etching, the columnar array structure is transferred to the silicon carbide substrate, and the structural height of the micron column is precisely controlled;

[0057] (4) 300 nm of copper was plated with an electron beam evaporation coating apparatus, and then reactive ion etching was used for 40 min to obtain a micro-nano structure.

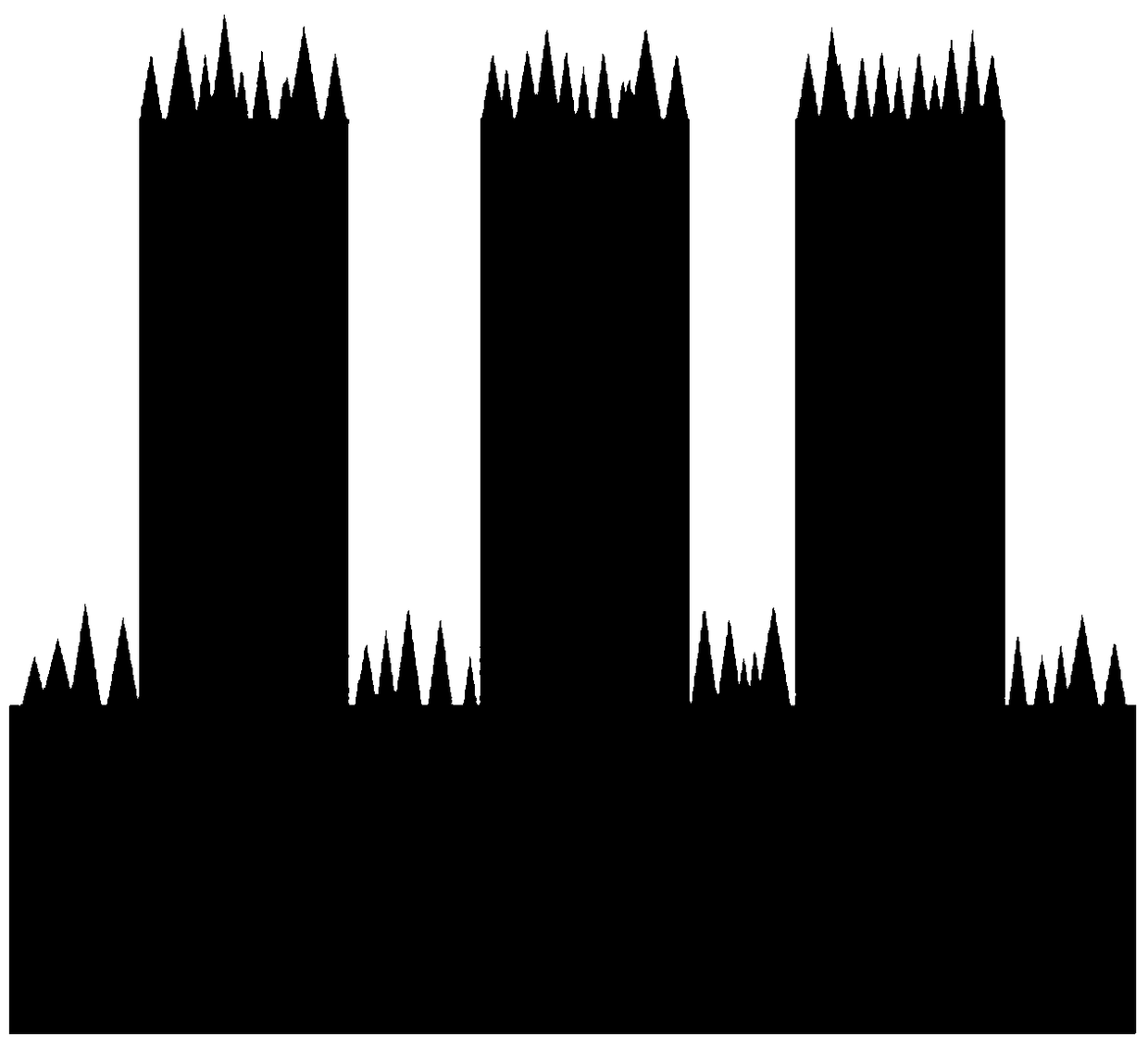

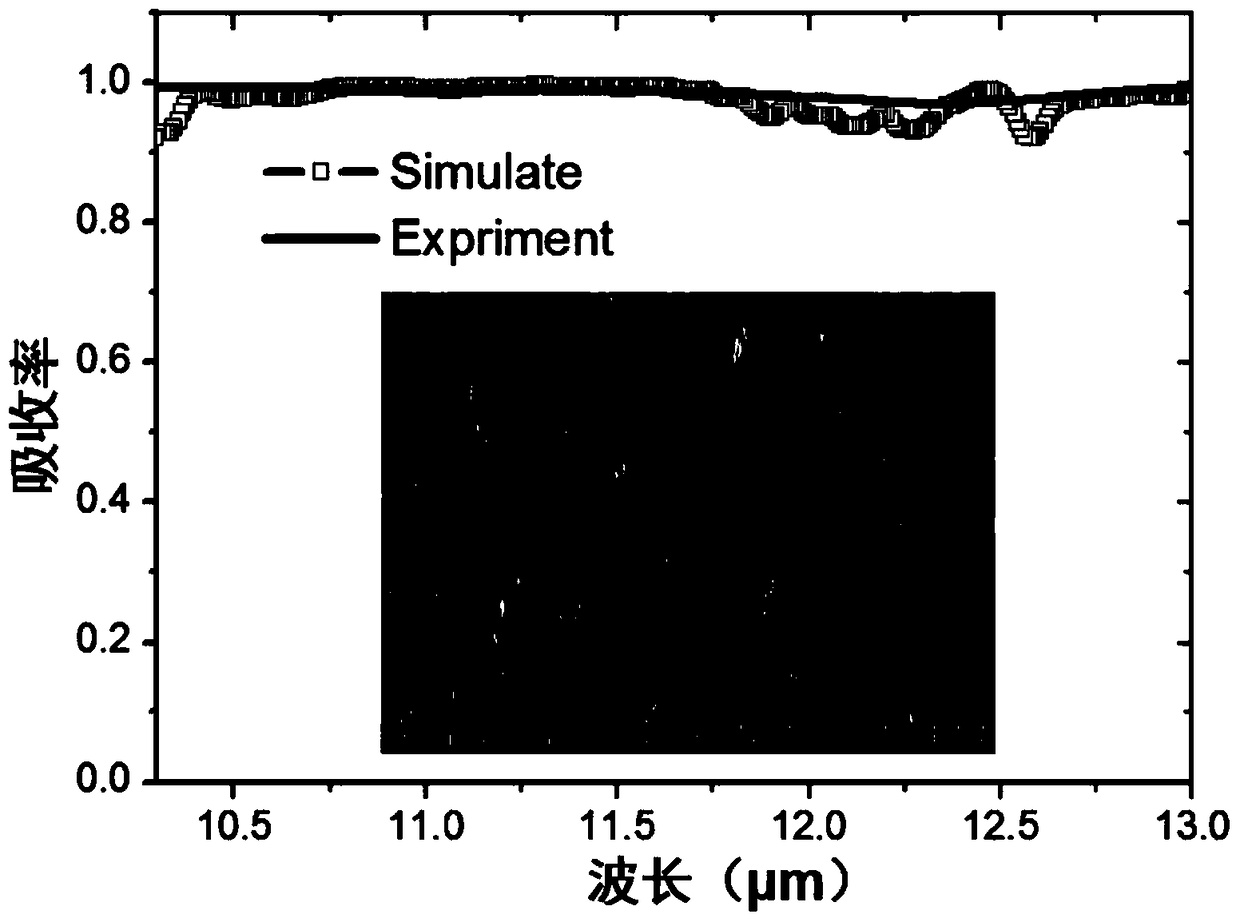

[0058] The prepared micro-nano array structure is as follows figure 2 As shown, the micro-pillar is a cylinder with a period of 8 μm, a diameter of 6 μm, and a...

Embodiment 2

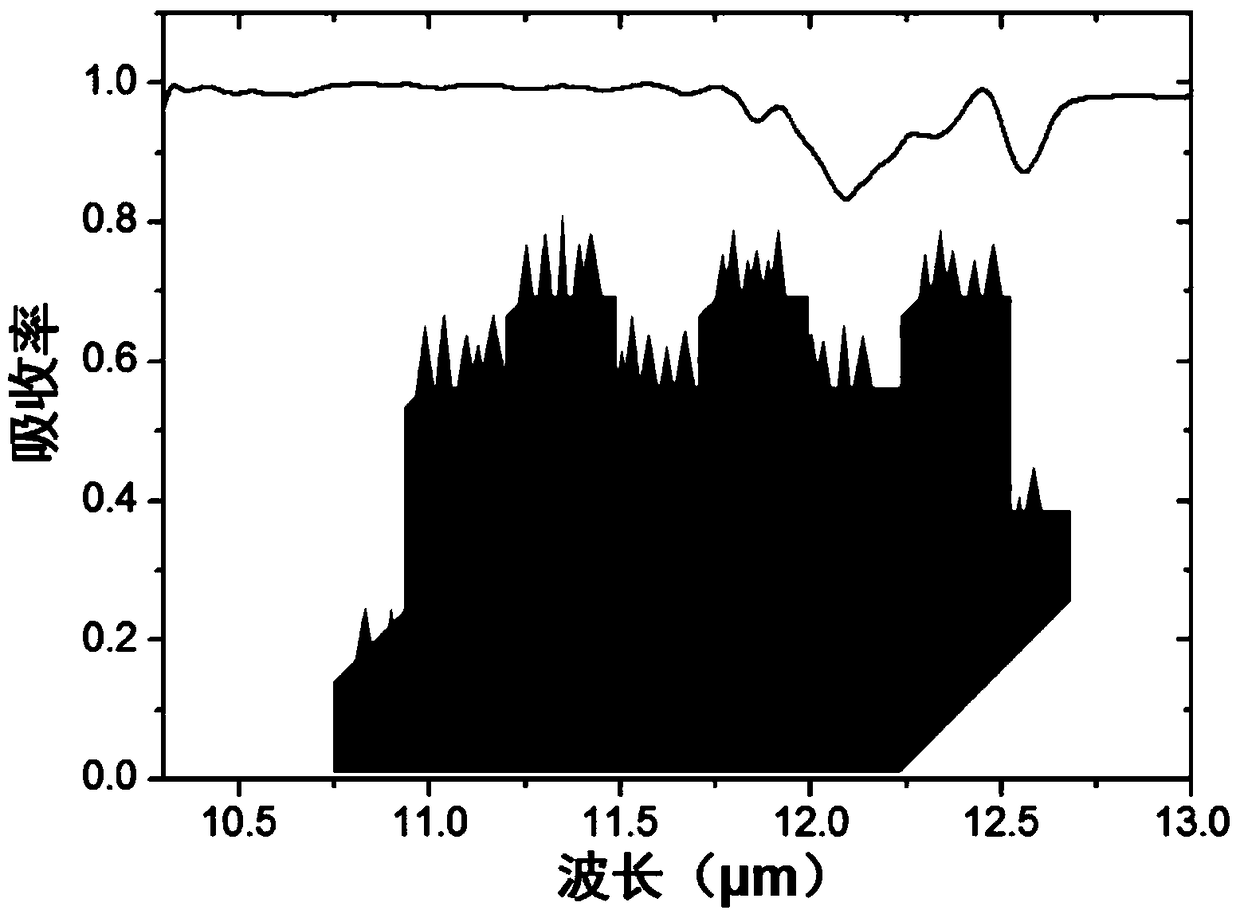

[0060] The preparation method is the same as in Example 1, and the prepared micro-nano array structure is as follows: image 3 As shown, the microcolumn is a square column with a period of 6 μm, a side length of 4 μm, and a height of 14 μm; the nanostructure is a nanocone with a bottom cross-sectional area of 0.04-4 μm 2 , with a height of 2-8 μm. The absorbance in the band around 10-13μm is greater than 80%.

Embodiment 3

[0062] The preparation method is the same as in Example 1, and the prepared micro-nano array structure is as follows: Figure 4 As shown, the micro-column is an octagonal column with a period of 6 μm. The cross-shaped column is composed of two cuboids intersecting. Each cuboid is 4 μm long, 1.657 μm wide, and 8.5 μm high; the nanostructure is a nanocone. The cross-sectional area is 0.04-4μm 2 , with a height of 2-8 μm. The absorbance in the band around 10-13μm is greater than 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com