Preparation method of nitrogen-doped graphene quantum dots

A technology of graphene quantum dots and nitrogen-doped graphene, which is applied in the field of preparation of nitrogen-doped graphene quantum dots, and achieves the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

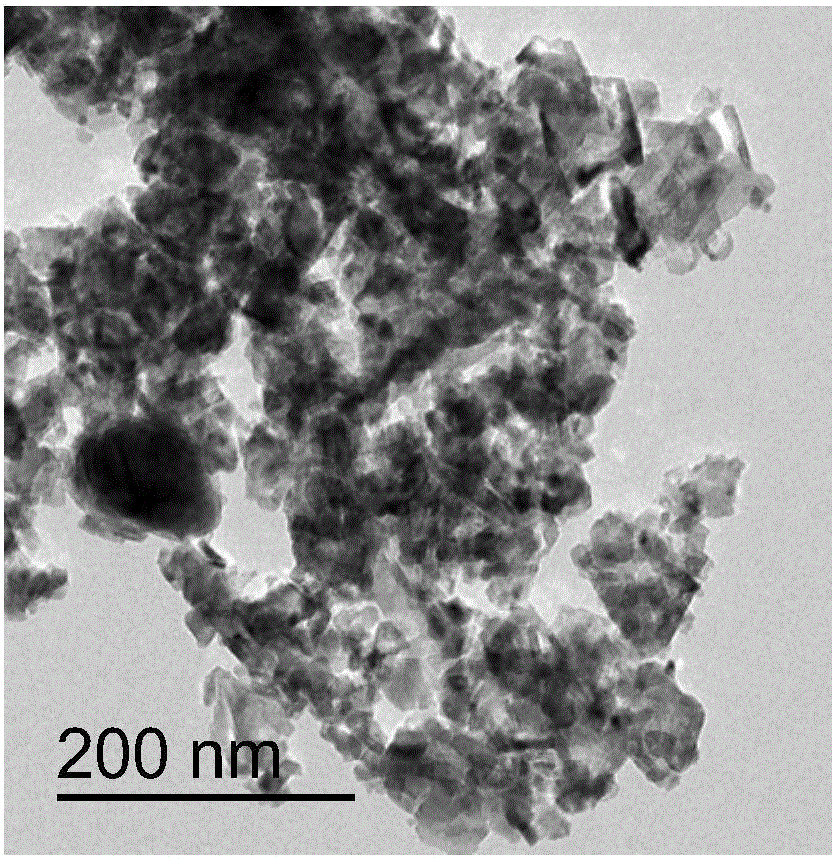

[0031] Weigh 5.0g of trinitrotriaminobenzene (TATB) and add 40.0g of concentrated sulfuric acid (H 2 SO 4 ), stirred for 30 minutes to dissolve. The dissolved solution was transferred to a 200ml reactor, and placed in a high-temperature oven at 150°C for 1 hour. After the reaction is completed, freeze and open the reaction kettle, add 100mL of distilled water, and then pour it into a dialysis bag for dialysis for 2-3 days to remove concentrated sulfuric acid, so that the pH of the solution is 6-7, and obtain light yellow water-soluble nitrogen-doped graphene. The aqueous solution was freeze-dried for 5 days to obtain black nitrogen-doped graphene powder, the morphology of which is shown in figure 1 shown.

Embodiment 2

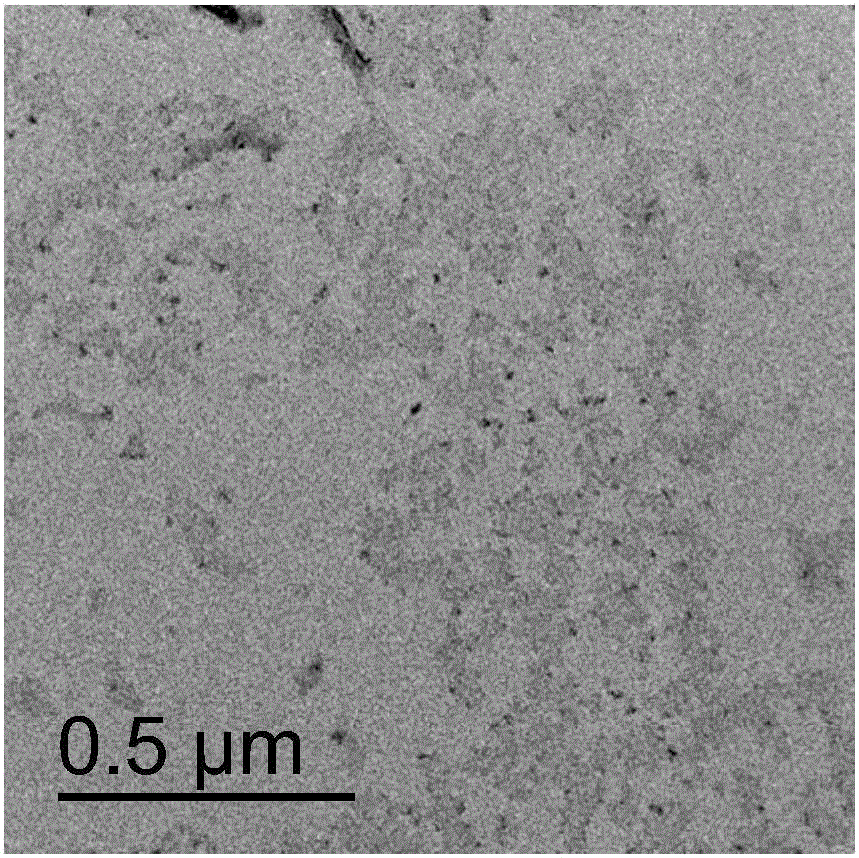

[0033] Weigh 5.0g of trinitrotriaminobenzene (TATB) and add 40.0g of concentrated sulfuric acid (H 2 SO 4 ), stirred for 30 minutes to dissolve. The dissolved solution was transferred to a 500ml reactor, and placed in a high-temperature oven at 280°C for 1 hour. After the reaction is completed, freeze and open the reactor, add 300mL of distilled water, and pour into a dialysis bag for dialysis for 2-3 days to remove concentrated sulfuric acid, so that the pH of the solution is 6-7, and obtain light yellow water-soluble nitrogen-doped graphene. The aqueous solution was freeze-dried for 5 days to obtain black nitrogen-doped graphene powder, the morphology of which is shown in figure 2 shown.

Embodiment 3

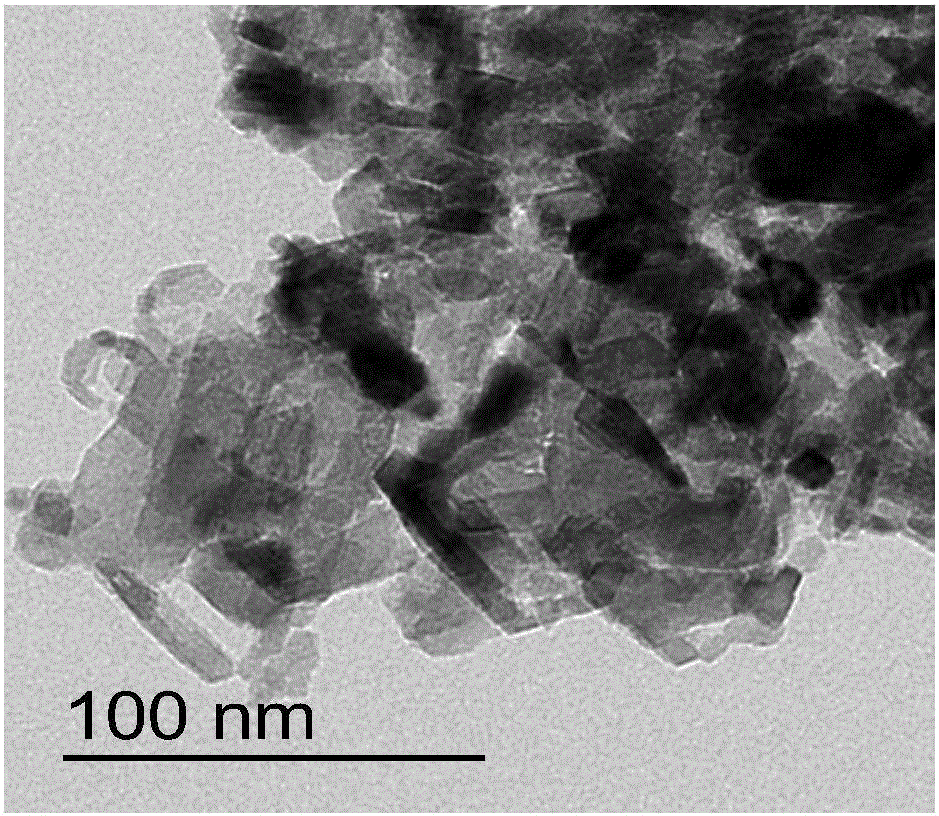

[0035] Weigh 5.0g of trinitrotriaminobenzene (TATB) and add 60.0g of concentrated sulfuric acid (H 2 SO 4 ), stirred for 30 minutes to dissolve. The dissolved solution was transferred to a 500ml reactor, and placed in a high-temperature oven at 200°C for 4 hours. After the reaction is completed, freeze and open the reaction kettle, add 300mL of distilled water, and then pour it into a dialysis bag for dialysis for 2-3 days to remove concentrated sulfuric acid, so that the pH of the solution is 6-7, and obtain light yellow water-soluble nitrogen-doped graphene. The aqueous solution was freeze-dried for 5 days to obtain black nitrogen-doped graphene powder, the morphology of which is shown in image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com