Ozone catalytic advanced treatment method and treatment device for cold rolling dilute alkali wastewater

A technology for advanced treatment of dilute alkali wastewater, applied in the field of water treatment, can solve the problems of high COD environmental pollution in biochemical effluent, achieve good social and environmental benefits, long service life, and easy to decompose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

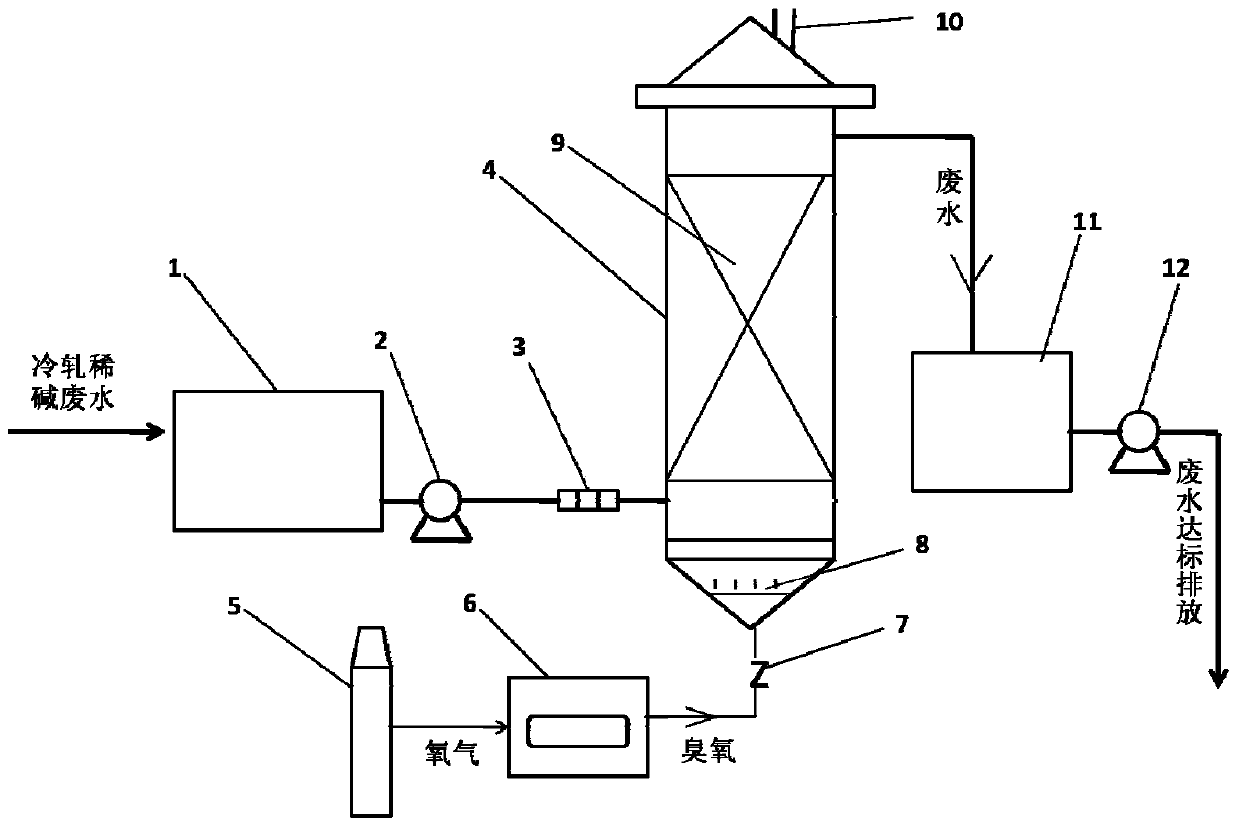

[0042] A cold-rolled dilute alkali wastewater ozone catalytic oxidation advanced treatment process system, water inlet tank, water inlet pump, liquid flow meter, ozone bubble tower reaction tower, oxygen cylinder, ozone generator, check valve, ozone diffusion distributor, ozone catalyst , Ozone gas outlet, outlet pool, outlet pump.

[0043] In this embodiment, the pH of the cold-rolled dilute alkali biochemical effluent before treatment is 8.7, the conductivity is 3760 us / cm, and the COD is 92 mg / L.

[0044] The cold-rolled dilute alkali biochemical effluent enters the water inlet pool through the pipeline. Then enter the ozone bubble tower reaction tower through the water inlet pump. The liquid flow meter with automatic control system controls the flow rate of cold-rolled dilute alkali biochemical effluent into the ozone bubble tower reaction tower. An ozone quencher is installed in the gas outlet at the top of the bubble tower to eliminate excess ozone so as not to dischar...

Embodiment 2

[0051] A cold-rolled dilute alkali wastewater ozone catalytic oxidation advanced treatment process system, water inlet tank, water inlet pump, liquid flow meter, ozone bubble tower reaction tower, oxygen cylinder, ozone generator, check valve, ozone diffusion distributor, ozone catalyst , Ozone gas outlet, outlet pool, outlet pump.

[0052] In this embodiment, the pH of the cold-rolled dilute alkali biochemical effluent before treatment is 6.9, the conductivity is 1790 us / cm, and the COD is 73 mg / L.

[0053] The cold-rolled dilute alkali biochemical effluent enters the water inlet pool through the pipeline. Then enter the ozone bubble tower reaction tower through the water inlet pump. The liquid flow meter with automatic control system controls the flow rate of cold-rolled dilute alkali biochemical effluent into the ozone bubble tower reaction tower.

[0054] The height-to-diameter ratio of the ozone bubbling reaction tower is 5:1, the superficial gas velocity is 0.15m / s, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com