Special organic fertilizer for radish, and preparation method thereof

An organic fertilizer and radish technology, which is applied in the special organic fertilizer for radish and its preparation field, can solve problems such as failure to meet the normal growth of radish, insufficient utilization of active ingredients, waste of resources, etc., and achieve shortened preparation time, low production requirements, and low production costs. The effect of time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

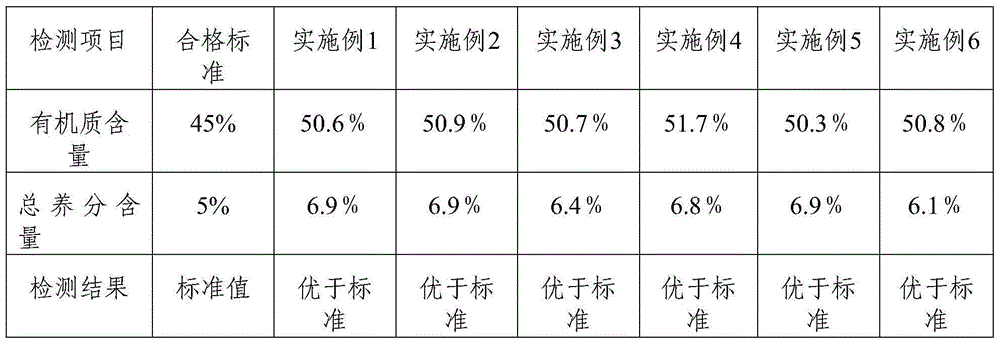

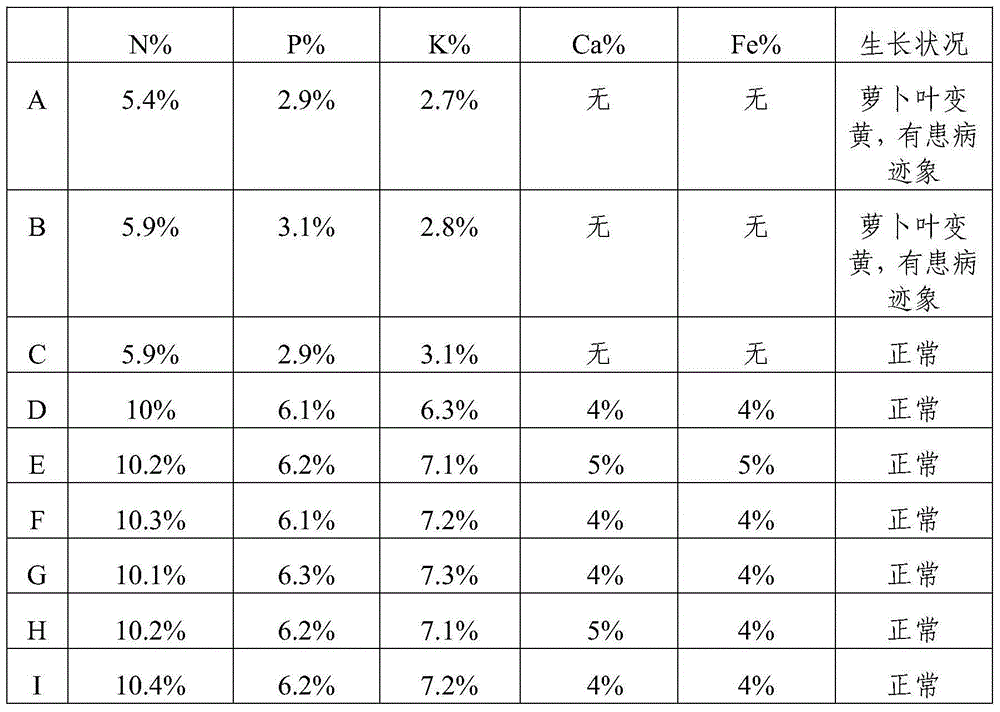

Examples

Embodiment 1

[0022] Recipe: 40kg of vermicompost, 25kg of cow dung, 27kg of oil, 1.3kg of starter, 18kg of straw, and 33kg of water hyacinth.

[0023] Preparation:

[0024] a. Raw material pretreatment: first dry the water hyacinth until the water content is 5%, crush it to 300 meshes, then dry the vermicompost, cow dung, oil dry, and straw until the water content is 35-45%, and then add the starter and The water hyacinth processed through drying and crushing is mixed evenly;

[0025] b. Fermentation treatment: Put the uniformly mixed raw materials into the fermentation room for fermentation treatment. The temperature of the fermentation room is controlled at 60°C, the relative humidity is controlled at 55%, and the treatment time is 5 days;

[0026] c. Granulation and drying: the fermented organic fertilizer is granulated and dried, and after cooling, the finished organic fertilizer for radish is obtained.

Embodiment 2

[0028] Recipe: 60kg of vermicompost, 35kg of cow dung, 37kg of oil, 2.3kg of starter, 28kg of straw, and 43kg of water hyacinth.

[0029] Preparation:

[0030] a. Raw material pretreatment: first dry the water hyacinth until the water content is 5%, and then crush it to 300 meshes, then dry the vermicompost, cow dung, oil dry, and straw until the water content is 35%, then add the starter and dry The pulverized water hyacinth is mixed evenly;

[0031] b. Fermentation treatment: Put the uniformly mixed raw materials into the fermentation room for fermentation treatment. The temperature of the fermentation room is controlled at 65°C, the relative humidity is controlled at 55%, and the treatment time is 6 days;

[0032] c. Granulation and drying: the fermented organic fertilizer is granulated and dried, and after cooling, the finished organic fertilizer for radish is obtained.

Embodiment 3

[0034] Formula: 45kg of vermicompost, 28kg of cow dung, 30kg of dried oil, 1.6kg of starter, 21kg of straw, and 36kg of water hyacinth.

[0035] Preparation:

[0036] a. Raw material pretreatment: first dry the water hyacinth until the water content is 6%, and then crush it to 400 meshes, then dry the vermicompost, cow dung, oil dry, and straw until the water content is 40%, then add the starter and dry The pulverized water hyacinth is mixed evenly;

[0037] b. Fermentation treatment: Put the uniformly mixed raw materials into the fermentation room for fermentation treatment. The temperature of the fermentation room is controlled at 70°C, the relative humidity is controlled at 60%, and the treatment time is 7 days;

[0038] c. Granulation and drying: the fermented organic fertilizer is granulated and dried, and after cooling, the finished organic fertilizer for radish is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com