High-covering black matte silk-screen printing ink for PET base material

A black matte, silk-screen ink technology, applied in the field of ink, can solve problems such as unfavorable notebook computer control, reduced process yield, complex process, etc., and achieves excellent covering performance, reduced gloss, and high finish.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

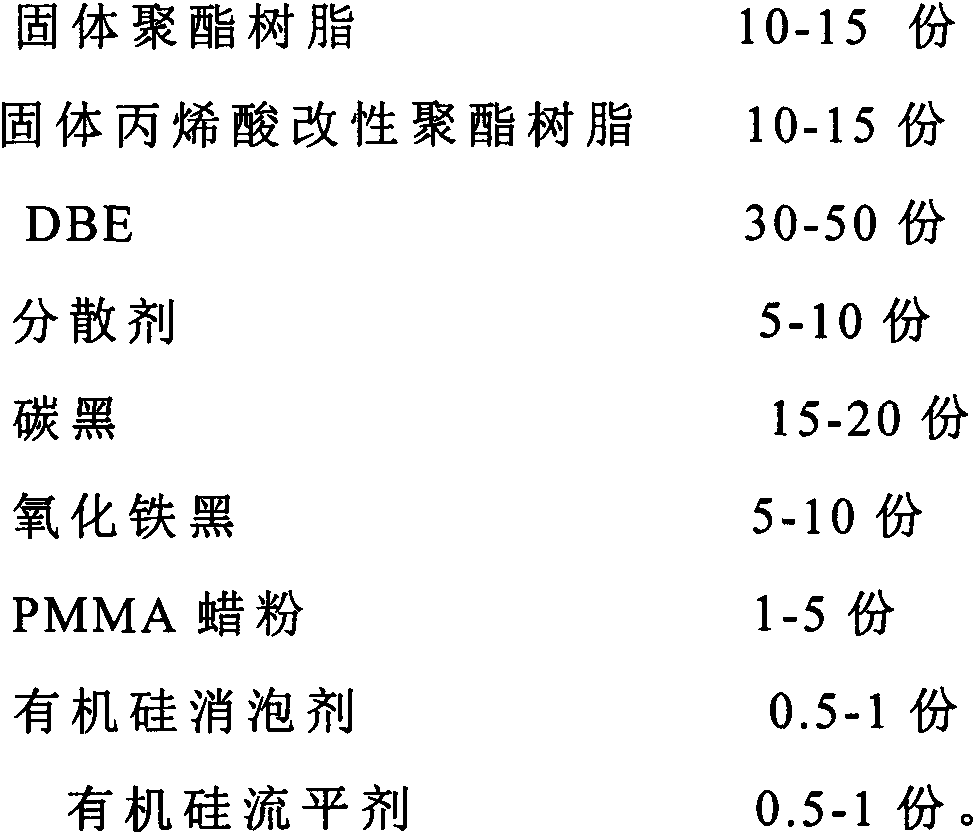

Embodiment 1

[0038] By weight, get 45 parts of solvent DBE, 8 parts of dispersant (German BYK-163), add 12 parts of solid polyester resin (Korea SK ES100) and solid acrylic modified polyester resin (Shanghai Lanyi S-800) 12 parts, carbon black 18 parts, iron oxide black 6 parts, stir at 1000 rpm for 2 hours at high speed, after stirring evenly, pass it through the sand mill for four times, and the air pressure of the sand mill for the first time : 0.4mpa, the air pressure of the second, third, and fourth times is 0.2mpa; add 1.5 parts of PMMA wax powder, 0.8 parts of silicone defoamer (BYK-141, Germany), and silicone fluid Leveling agent (German BYK-333) 0.4 parts, disperser to make it evenly dispersed, sand mill sanding once, the sand mill air pressure is 0.4mpa; obtain PET base material with high covering black matte screen printing ink.

[0039] The carbon black is medium pigment carbon black, the oil absorption value is 300, and the average particle diameter is 25nm; the average partic...

Embodiment 2

[0042] In parts by weight, take 50 parts of solvent DBE, 8 parts of BYK-163 dispersant, add 14 parts of solid polyester resin, 14 parts of solid acrylic modified polyester resin, 16 parts of carbon black, and 6 parts of iron oxide black in the dispersed state , 1000 revolutions per minute and high-speed stirring for 2 hours. After stirring evenly, pass through the sand mill for four times. Add 1.5 parts of PMMA wax powder, 0.8 parts of silicone defoamer (BYK-141, Germany), and 0.4 parts of silicone leveling agent (BYK-333, Germany) to the finished sanding product, and disperse it with a disperser. Evenly, the sand mill is sanded once, and the air pressure of the sand mill is 0.4mpa; the high-covering black matte screen printing ink for PET substrates is obtained. The carbon black is medium pigment carbon black with an oil absorption value of 300 and an average particle diameter of 25nm; the average particle diameter of the iron oxide black is 0.40 μm and an oil absorption valu...

Embodiment 3

[0045] In parts by weight, get 40 parts of solvent DBE, 8 parts of dispersant (Byk Chemical BYK-163), add 12 parts of solid polyester resin, 12 parts of solid acrylic modified polyester resin, and 16 parts of carbon black in the dispersed state , 8 parts of iron oxide black, 1000 revolutions per minute and high-speed stirring for 2 hours, after stirring evenly, pass through the sand mill for four times, the air pressure of the sand mill for the first time: 0.4mpa, the second, third and fourth times the air pressure is equal 0.2mpa; add 1.5 parts of PMMA wax powder, 0.8 parts of silicone defoamer (BYK-141, Germany), and 0.4 parts of silicone leveling agent (BYK-333, Germany) to the above sanded finished product , the dispersing machine makes it disperse evenly, and the sand mill is sanded once, and the air pressure of the sand mill is 0.4mpa; Obtain the black matte screen printing ink with high covering for PET substrate.

[0046] The carbon black is a medium pigment carbon bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com