Radiation resistant inner wall latex paint

An interior wall latex paint and anti-radiation technology, applied in the field of latex paint, can solve the problems of lack of anti-radiation and stain resistance, different thermal expansion and contraction, poor anti-ultraviolet ability, etc., to achieve the suppression of pan-alkaline phenomenon, Increased crosslink density and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] G1: octaphenyl cage polysilsesquioxane modified sulfonated polyimide, prepared by the following method:

[0032] In a 100mL dry three-neck flask, add 1.6mmol 2,2'-bis(4-sulfophenoxy)biphenyldiamine, 12.5mL m-creso1 and 0.8mL triethylamine successively, and protect with nitrogen gas and Magnetic stirring; after 2,2'-bis(4-sulfonic acid phenoxy)biphenyldiamine is completely dissolved, then add 1.55mmol 3,4,9,10-perylenetetracarboxylic anhydride, 3.0mmol benzoic acid And 0.6mL isoquinoline; after stirring at room temperature for 1h, raise the temperature to 80°C for 4h, 180°C for 20h; After that, the polymer was collected by suction filtration, and dried in a vacuum oven at 60°C for 20 hours to obtain an amino-terminated sulfonated polyimide prepolymer;

[0033] 100 grams of the amino-terminated sulfonated polyimide prepolymer are first dissolved in 1000 grams of polyphosphoric acid containing 86 wt% phosphorus pentoxide, and then the amino-terminated sulfonated polyimide...

Embodiment 1

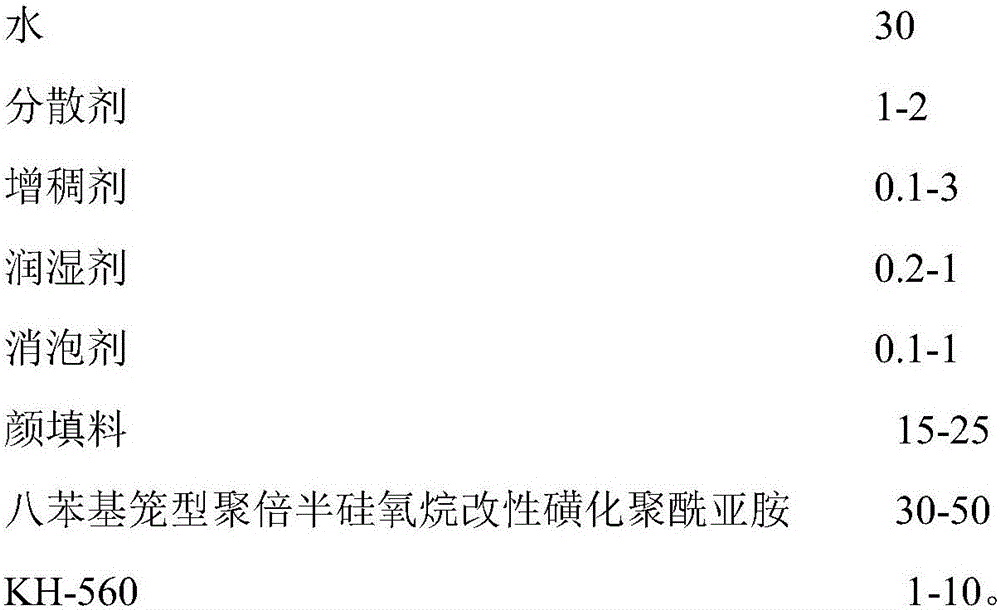

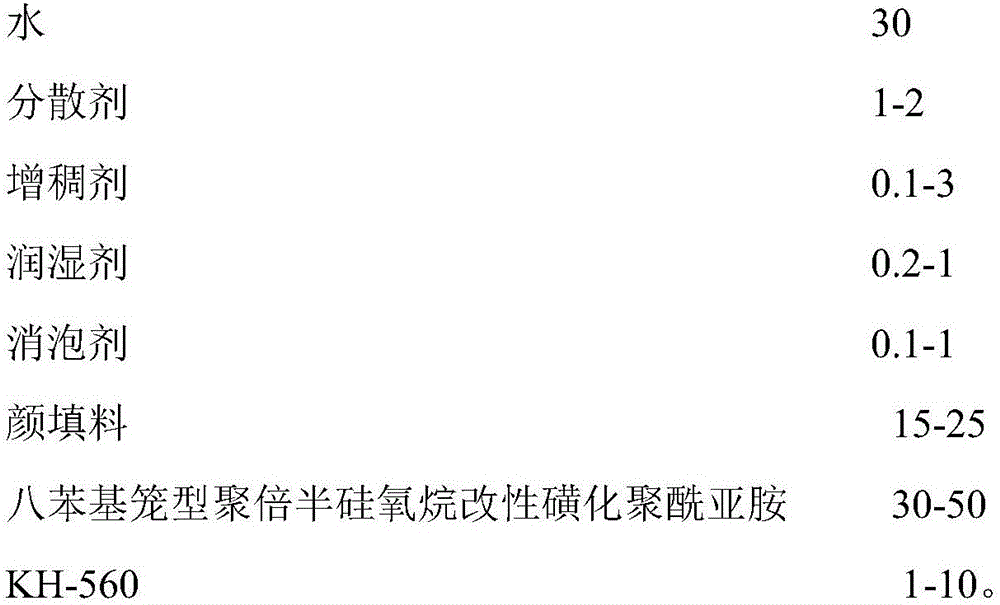

[0044] In parts by weight, add 30 parts of A1, 2 parts of B1, 1 part of C1, 1 part of D1, 1 part of E1, 20 parts of F1, 35 parts of G1 and 8 parts of H1 into the mixer and mix them thoroughly for 10 minutes, and then discharge to obtain Anti-radiation interior wall latex paint. The radiation-proof interior wall latex paint is coated on the interior wall to complete the construction.

Embodiment 2

[0046] In parts by weight, add 30 parts of A1, 2 parts of B1, 1 part of C1, 1 part of D1, 1 part of E1, 20 parts of F1, 35 parts of G2 and 8 parts of H1 into the mixer and mix them thoroughly for 10 minutes, and then discharge Anti-radiation interior wall latex paint. The radiation-proof interior wall latex paint is coated on the interior wall to complete the construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com