Organic soil conditioner and preparation method thereof

An organic soil and conditioner technology, applied in soil conditioning materials, plant growth regulators, botanical equipment and methods, etc., can solve the problems of poor air permeability, soil damage, nutrient ratio imbalance, etc., to improve air permeability and The effect of moisture content, relieving soil compaction, and reducing incidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An organic soil conditioner is prepared by fermentation of the following materials: 50 kg of municipal sludge, 10 kg of mushroom dregs, 20 kg of rice husk powder, 10 kg of vermiculite, and 10 kg of Bacillus subtilis.

[0025] The specific preparation method is:

[0026] 1) Weigh all the raw materials except Bacillus subtilis according to the above ratio, crush them until they pass through an 80-mesh sieve, and mix them evenly;

[0027] 2) Take out the Bacillus subtilis that has undergone tertiary cultivation and propagation according to the above ratio, mix it with the raw materials in step 1), adjust the humidity of the mixed material at about 40%, and carry out aerobic solid-state fermentation at room temperature, and the fermentation temperature is 20-60 degree, the fermentation time is 12 days.

[0028] 3) The product obtained in step 2) is dried at low temperature, and then crushed through a 100-mesh sieve to obtain the organic soil conditioner.

Embodiment 2

[0030] An organic soil conditioner is prepared by fermentation of the following materials: 40 kg of municipal sludge, 20 kg of mushroom dregs, 20 kg of rice husk powder, 15 kg of vermiculite, and 15 kg of Bacillus subtilis.

[0031] 1) Weigh all the raw materials except Bacillus subtilis according to the above ratio, crush them until they pass through an 80-mesh sieve, and mix them evenly;

[0032] 2) Take out the Bacillus subtilis that has undergone tertiary cultivation and propagation according to the above ratio, mix it with the raw materials in step 1), adjust the humidity of the mixed material at about 40%, and carry out aerobic solid-state fermentation at room temperature, and the fermentation temperature is 20-60 degree, the fermentation time is 15 days.

[0033] 3) The product obtained in step 2) is dried at low temperature, and then crushed through a 100-mesh sieve to obtain the organic soil conditioner.

Embodiment 3

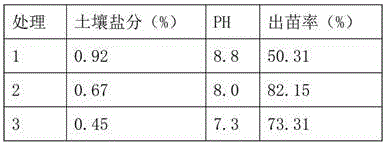

[0035] The field test was carried out from April to June 2015 in a cotton field in the north of Shihezi City, Xinjiang. The basic physical and chemical properties of the soil are: clay, organic matter content 0.813%, available nitrogen 53.21ppm, available phosphorus 8.17ppm, available potassium 227ppm, soil Salt 0.91, pH 8.9. The tested crop variety was Xinkaiyu 13. Three treatments were set up in the test. Treatment 1 was the control without soil conditioner; Treatment 2 was the organic soil conditioner of the present invention; Treatment 3 was a certain brand of soil conditioner purchased from the Shihezi Agricultural Materials Store. Apply evenly to the surface one day before irrigation, and the dosage per mu is 1kg. The area of the community is 100m 2 , arranged in random blocks, repeated 3 times, and field management was in accordance with local customs. After 20 days, take a 0-20cm soil sample according to the five-point sampling method to measure the salinity and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com