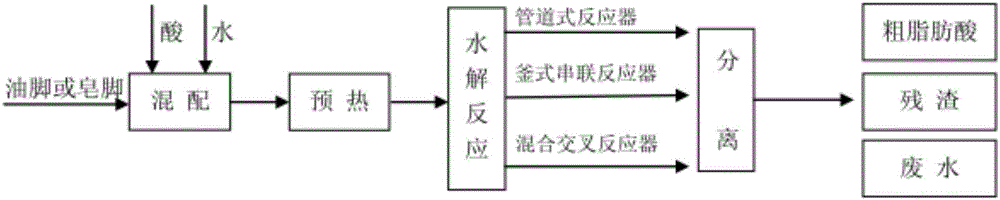

Continuous hydrolysis method for oil foots and soap foots

A technology of soapstock and oilstock, which is applied in the field of continuous hydrolysis of oilstock and soapstock to prepare high value-added products. It can solve the problems of increased material side reactions, environmental and water pollution, and low acid value of acidified oil to reduce emissions. The effect of less waste water and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add the oil foot and soap stock to the mixing kettle, and add 40% water of the oil foot and soap stock mass, dropwise add 80wt.% acetic acid until the pH value of the mixture is 6, stir until uniform; The final liquid material is sent to a preheater at 200-210 ° C; the preheated material is sent to a pipeline continuous reactor for reaction, the reaction temperature is 210 ° C, the pressure is 1.6 MPa, and the control material flows through the pipeline reaction The residence time of the reactor was 50 min; after the reaction, the material was separated to obtain crude fatty acid, solid residue and waste water. The acid value of the crude fatty acid was determined to be 185 mgKOH / g, and the yield was 55%. The pH value of the waste water was 6, and in the waste water Contains 15wt.% glycerin.

Embodiment 2

[0023] Add the oily bottoms and soapstocks to the mixing kettle, add 32% water of the oily bottoms and soapstocks, add dropwise a concentration of 35 wt.% formic acid until the pH of the mixture is 6, and stir until uniform; The homogenized liquid material is sent to a preheater at 170-180 °C; the preheated material is sent to a pipeline continuous reactor for reaction, the reaction temperature is 180 °C, the pressure is 0.6 MPa, and the material flows through the pipeline type continuous reactor. The residence time of the reactor was 20 min; after the reaction, the material was separated to obtain crude fatty acid, solid residue and waste water. The acid value of the crude fatty acid was measured to be 175 mgKOH / g, and the yield was 42%. The pH value of the waste water was 6, and the waste water Contains 8wt.% glycerin.

Embodiment 3

[0025] Add oil foot and soap stock to the mixing kettle, and add oil foot and soap stock quality 36% water, drop concentration is 70 wt.% acetic acid and concentration is 50 wt.% phosphoric acid to the pH value of mixed solution 6. Stir until uniform; send the mixed liquid material into a preheater at 190-200°C; send the preheated material into a pipeline continuous reactor for reaction at a reaction temperature of 200°C and a pressure of 1.0 MPa, the residence time of the control material flowing through the pipeline reactor is 40 min; after the reaction, the material is separated to obtain crude fatty acid, solid residue and waste water. The acid value of the crude fatty acid is 180 mgKOH / g, and the yield is 48%. The pH of the wastewater was 6, and the wastewater contained 12 wt.% glycerol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com