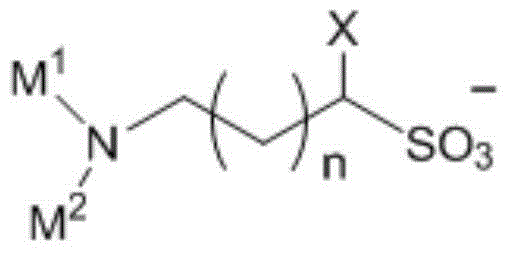

Method for pretreating biomass by using dual-functionalized ionic liquid to improve enzymolysis efficiency

A technology for pretreatment of biomass and ionic liquid, which is applied in the field of utilization and treatment of agricultural and forestry biomass resources to achieve the effects of improving the yield of reducing sugar and enhancing the efficiency of enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] [Et 4 N][Me 2 NC 4 SO 3 ] Pretreatment at 120℃ improves the efficiency of enzymatic hydrolysis of eucalyptus bark

[0039] (1) Pretreatment: Accurately weigh 500 mg of bark powder (40-80 mesh in particle size) and 10 g [Et 4 N][Me 2 NC 4 SO 3 ] ionic liquid, placed in a 100ml round bottom flask, stirred at 120°C for 10 hours; after cooling to room temperature, add 40ml of deionized water to wash, filter, and then wash the filter residue with 40ml of deionized water for 5 times, and remember to Pre-treated eucalyptus bark.

[0040] (2) Enzyme hydrolysis experiment: accurately weigh 20 mg of eucalyptus bark after pretreatment, place in a 50 ml Erlenmeyer flask with stopper, add 7 ml of citrate buffer (50 mmol / L, pH 4.8) and cellulase, seal and place React in a constant temperature oscillator at 160r / min at 50°C. 200ul samples were taken regularly, and then taken out and placed in boiling water to quench the enzymolysis reaction. After centrifugation, the concentr...

Embodiment 2

[0044] [Et 4 N][i-PrNHC 3 SO 3 ] Pretreatment at 120℃ improves the efficiency of enzymatic hydrolysis of eucalyptus bark

[0045] (1) Pretreatment: Accurately weigh 500 mg of bark powder (40-80 mesh in particle size) and 10 g [Et 4 N][i-PrNHC 3 SO 3 ] ionic liquid, placed in a 100ml round bottom flask, stirred at 120°C for 10 hours; after cooling to room temperature, add 40ml of deionized water to wash, filter, and then wash the filter residue with 40ml of deionized water for 5 times, and remember to Pre-treated eucalyptus bark.

[0046] (2) Enzyme hydrolysis experiment: accurately weigh 20 mg of eucalyptus bark after pretreatment, place in a 50 ml Erlenmeyer flask with stopper, add 7 ml of citrate buffer (50 mmol / L, pH 4.8) and cellulase, seal and place React in a constant temperature oscillator at 160r / min at 50°C. 200ul samples were taken regularly, and then taken out and placed in boiling water to quench the enzymolysis reaction. After centrifugation, the concentrat...

Embodiment 3

[0050] [Ch][Et 2 NC 4 SO 3 ] Pretreatment at 120℃ improves the efficiency of enzymatic hydrolysis of eucalyptus bark

[0051] (1) Pretreatment: Accurately weigh 500mg of eucalyptus bark powder (40-80 mesh in particle size) and 10g of [Ch][Et 2 NC 4 SO 3 ] ionic liquid, placed in a 100ml round bottom flask, stirred at 120°C for 10 hours; after cooling to room temperature, add 40ml of deionized water to wash, filter, and then wash the filter residue with 40ml of deionized water for 5 times, and remember to Pre-treated eucalyptus bark.

[0052] (2) Enzyme hydrolysis experiment: accurately weigh 20 mg of eucalyptus bark after pretreatment, place in a 50 ml Erlenmeyer flask with stopper, add 7 ml of citrate buffer (50 mmol / L, pH 4.8) and cellulase, seal and place React in a constant temperature oscillator at 160r / min at 50°C. 200ul samples were taken regularly, and then taken out and placed in boiling water to quench the enzymolysis reaction. After centrifugation, the concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com