Preparation method of raw extraction fluid in wet vanadium extraction process and implementation equipment of preparation method

A process and wet technology, which is applied in the field of preparation of raw liquid in the wet vanadium extraction process, can solve the problems of affecting extraction efficiency, increasing production cost, high production cost, etc., and achieve the goal of ensuring extraction efficiency, uniformity of reduced materials, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

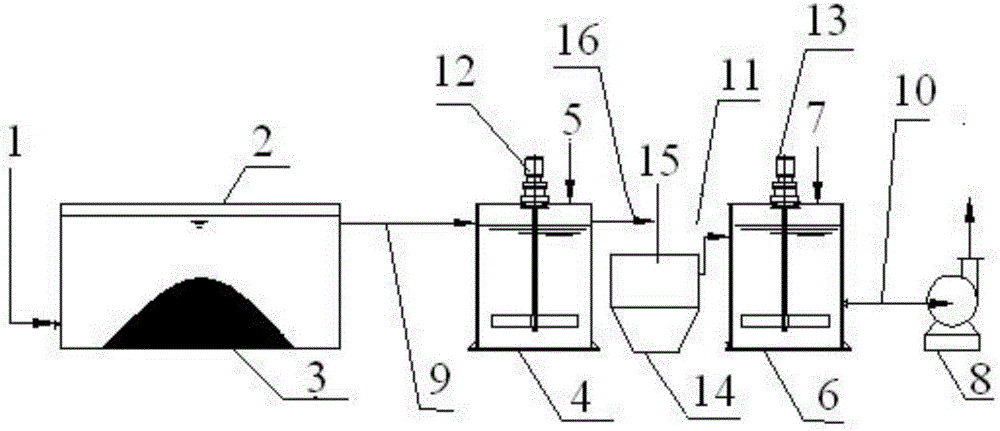

preparation example Construction

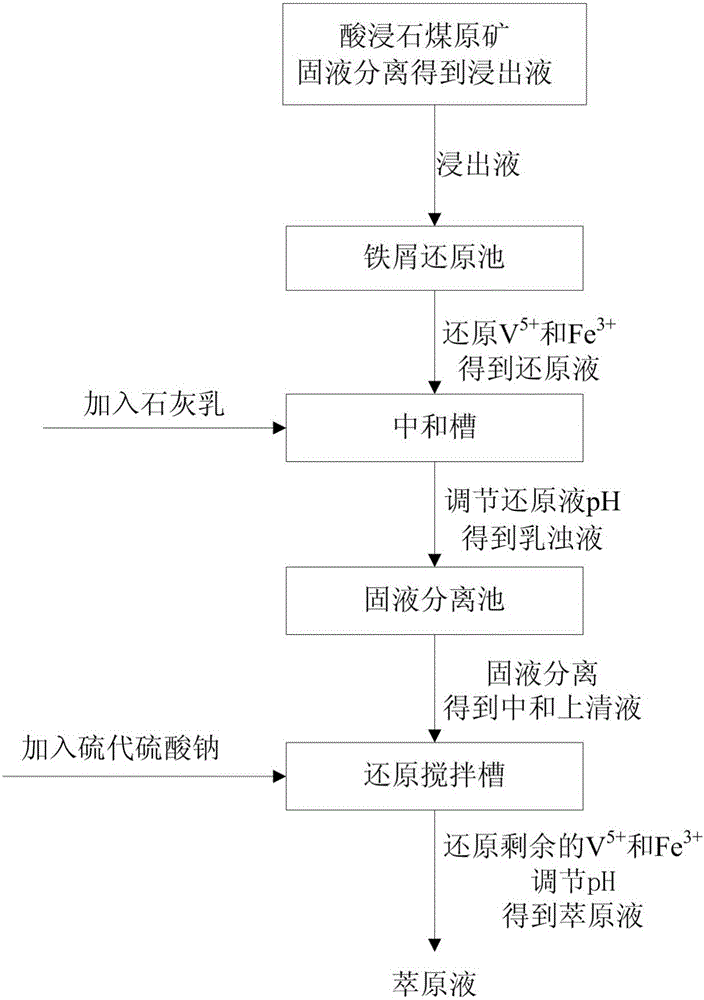

[0056] A method for preparing an extraction stock solution in a wet vanadium extraction process, comprising the following steps:

[0057] Step 1, adding sulfuric acid to the raw stone coal ore for acid leaching to obtain acid leaching pulp and then performing solid-liquid separation to obtain a leaching solution;

[0058] Step 2. Transport the leaching solution to the iron filings reduction tank where iron filings have been accumulated, and reduce pentavalent vanadium ions and ferric ions for 0-60 minutes until the concentration of ferric ions in the reducing solution is reduced to 1.70 g / When L, finish reducing, obtain reducing solution;

[0059] Step 3, after adjusting the pH of the reducing solution with milk of lime, after obtaining the emulsion, carry out solid-liquid separation to obtain a neutralized supernatant;

[0060] Step 4, adding sodium thiosulfate to the neutralized supernatant to reduce the remaining ferric ions and traces of pentavalent vanadium ions, and ad...

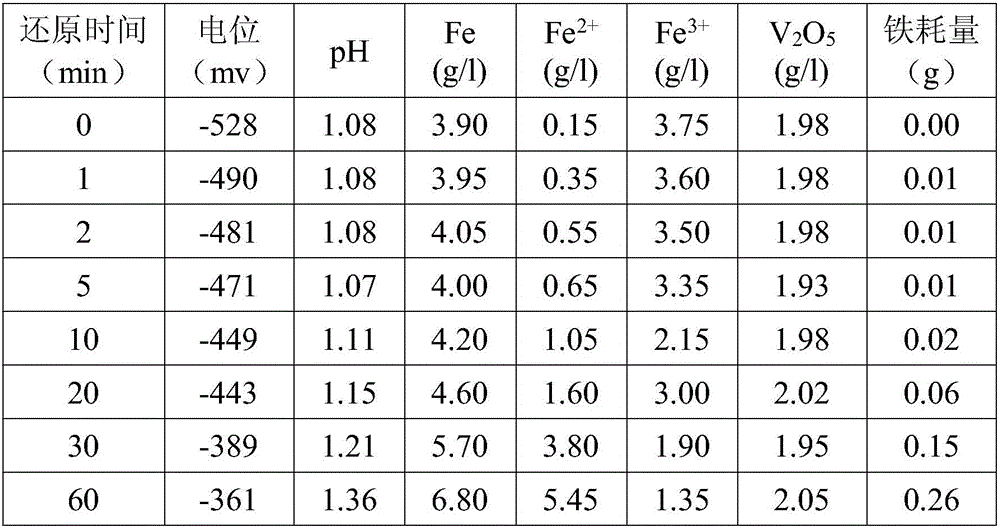

Embodiment 1

[0063] See Table 1 for the reduction data with iron filings filling amount of 6g:

[0064] Table 1

[0065]

Embodiment 2

[0067] See Table 2 for the reduction data of 10g of iron filings:

[0068] Table 2

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com