A rotatable nozzle type double-cluster hydraulic jet fracturing string and fracturing method

A technology of hydraulic jetting and rotating nozzles, applied in the field of oil and gas well fracturing, can solve the problems of uneven concentration, flow rate, pressure, and inability to adjust the orientation, achieves significant application effects, improves the success rate of directional perforation fracturing, and is practical in the field. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

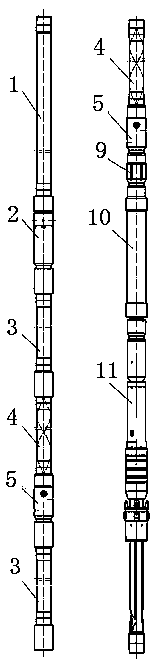

[0028] This embodiment provides a rotatable nozzle type double-cluster hydraulic jet fracturing string, such as figure 1 As shown, it includes oil pipe 1, safety joint 2, hydraulic injection device 1, hydraulic injection device 2, check valve 9, telescopic compensator 10 and bottom seal dragging fracturing packer 11, which are connected sequentially from top to bottom. It is characterized in that: the hydraulic injection device 1 and the hydraulic injection device 2 have the same structure, and they are all screwed in turn from top to bottom. 5 components of hydro jet;

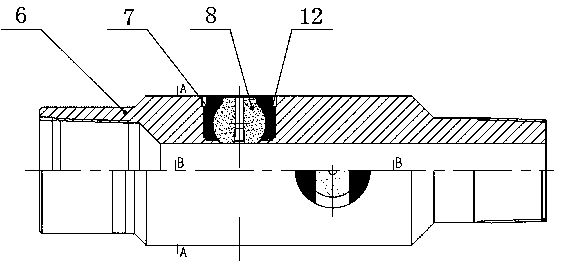

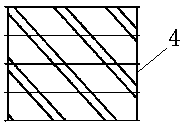

[0029] Such as figure 2 , Figure 4 and Figure 5 As shown, the rotatable nozzle type double-helix hydraulic injector 5 includes an injector body 6, and the inner cavity wall of the injector body 6 is provided with an Archimedes double-helix flow channel 13, and the Archimedes double-helix flow channel 13 is evenly distributed. There are four nozzle sleeves 7 distributed, and the nozzle sleeves 7 are thre...

Embodiment 2

[0042] On the basis of Example 1, the surface of the Archimedes double helix flow channel 13 is plated with a nickel-based alloy material. Both the rotatable-nozzle type double-helix water jet 5 and the inner cavity of the Archimedes double-helix nipple 4 are designed with the same Archimedes double-helix trapezoidal structure, and the grooves are coated with anti-wear and corrosion-resistant materials to prevent The change of the fluid swirl direction causes local erosion of the double helix groove flow channel, which improves the effect of the double helix swirl flow.

Embodiment 3

[0044] On the basis of Embodiment 1, the tapered roller bearing 12 and the nozzle sleeve 7 are interference fit, and the tapered roller bearing 12 and the spherical nozzle 8 are sealed and connected by a sealing pair. The radial rotatable angle range of the spherical nozzle 8 is ±45°. The nozzle cover 7 is connected with the injector body 6 through the external thread of the nozzle cover 7, which is convenient for nozzle maintenance or replacement when it is damaged.

[0045] The spherical nozzle 8 and the nozzle cover 7 are made of erosion-resistant cemented carbide tungsten carbide YG8 material, and the hardness reaches HRC92-95 after heat treatment; the tapered roller bearing 12 is made of high-carbon chromium bearing steel GCr15 material, which has a high Excellent contact fatigue strength, high wear resistance and dimensional stability. The Archimedes double helix short joint 4 and the rotatable nozzle type double helix hydraulic injector 5 are made of 35CrMo material, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com