Ultralow discharged flue gas analyzer based on ultraviolet multiple reflection pool technique

A flue gas analyzer and multiple reflection technology, which are applied in the analysis of materials, material analysis by optical means, instruments, etc., can solve the problem that the monitoring indicators cannot meet the ultra-low emission monitoring, and increase the gas absorption path and ensure stability. performance and reliability, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

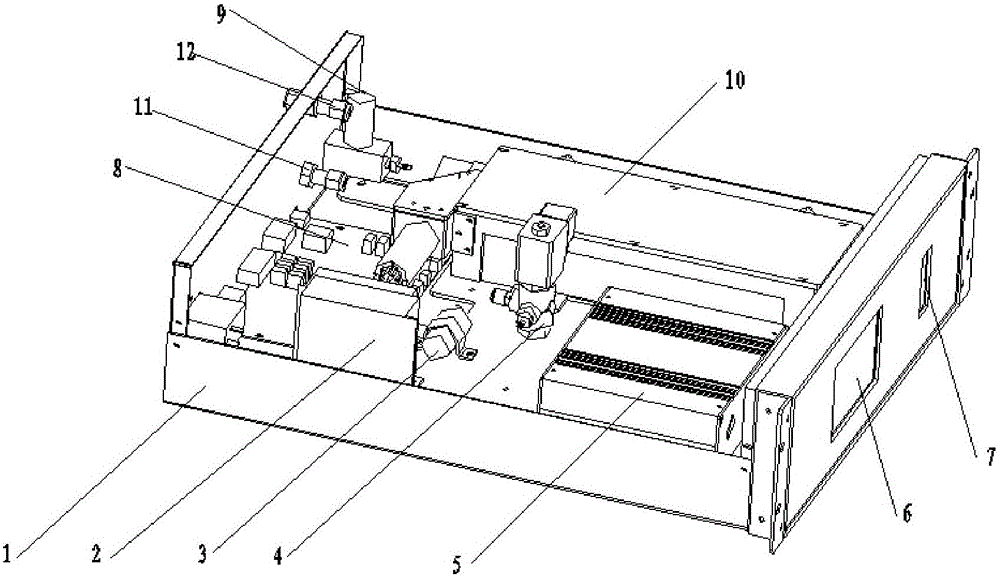

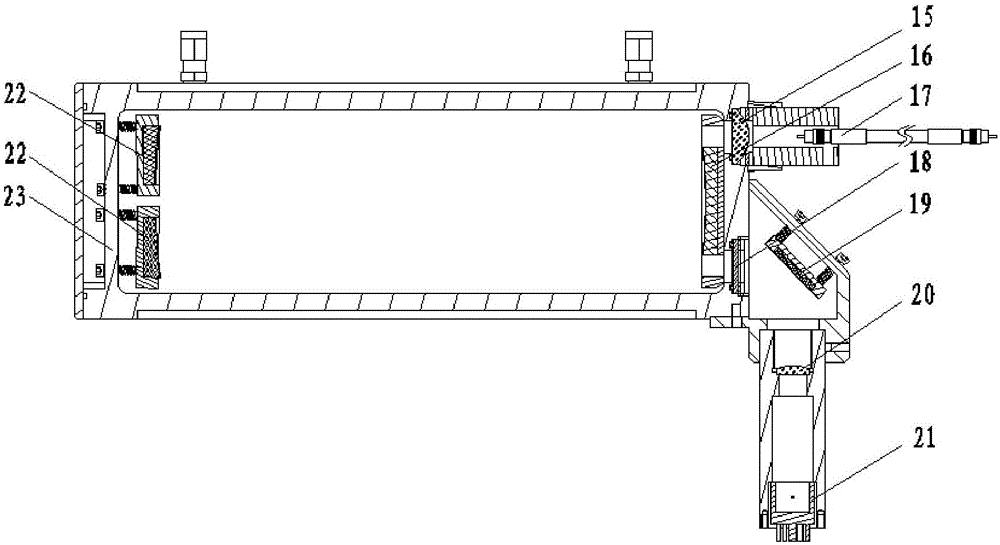

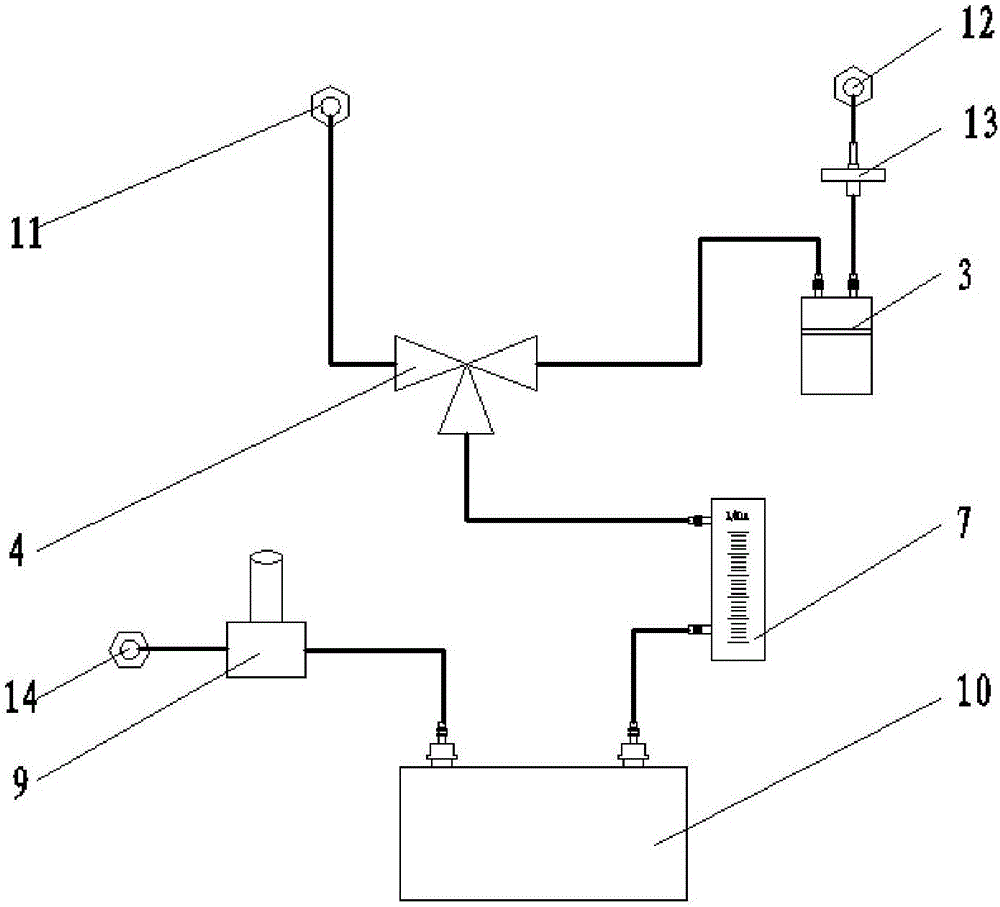

[0024] Such as Figure 1-3 As shown, an ultra-low emission flue gas analyzer based on ultraviolet multiple reflection cell technology includes an analyzer case 1, a sample gas inlet 11 and a zero gas inlet 12 are arranged on the rear panel of the analyzer case 1, and the analyzer case 1 is provided with a rotameter 7 and a touch screen 6 on the front panel, and an air outlet 14 is provided on the analyzer case 1, and a membrane filter 13, a gaseous pollutant detection module 10, a temperature control spectrum analysis module 5, two-position three-way valve 4, oxygen sensor 9, power supply module 2, diaphragm pump 3, main control module 8; gaseous pollutant detection module 10 and temperature control spectrum analysis module 5 are connected through quartz optical fiber 17;

[0025] The gaseous pollutant detection module includes a pulsed xenon lamp ultraviolet light source 21 and a detection chamber 23. The pulsed xenon lamp ultraviolet light source 21 is electrically connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com