Method of preparing dye-sensitized solar cell XS (X=Co, Ni) counter electrode

A technology of solar cells and dye sensitization, which is applied in the field of nanomaterial preparation technology and energy, and can solve the problems of expensive electrode materials and unsuitable for large-scale applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 The solvothermal condition is a mixed solution of CoS counter electrode prepared by reacting at 180°C for 18 hours with a molar ratio of cobalt acetate tetrahydrate: thiourea of 1:1.5, and a volume ratio of ammonia to ethanol of 5:2. Pour it into the reaction kettle, put the FTO conductive glass into the reaction kettle (the conductive surface is facing down), and react at 180° C. for 18 hours. The obtained FTO sample is washed with ethanol and dried to obtain a counter electrode.

[0023] TiO 2 Preparation of photoanode and battery performance test:

[0024] The photoanode of the dye-sensitized solar cell is prepared by coating the titanium dioxide nanocrystalline film, and the titanium dioxide slurry is made by hydrothermal synthesis (see S. Ito, T. Murakami, P. Comte, P. Liska, C. Grätzel, M. Nazeeruddin, M. Grätzel, Thin Solid Films, 516 (2008) 4613-4619).

[0025] Use N719 to sensitize the photoanode of the battery, and drop a redox electrolyte on the electro...

Embodiment 2

[0027] Example 2 The solvothermal condition is a mixed solution of NiS counter electrode prepared by reacting at 180°C for 18 hours with a molar ratio of nickel acetate tetrahydrate: thiourea of 1:1.5, and a volume ratio of ammonia to ethanol of 1:6. Pour it into the reactor, put the FTO conductive glass into the reactor (the conductive surface is facing down), and react at 180° C. for 18 hours. The obtained FTO sample is rinsed with ethanol and dried to obtain a counter electrode.

[0028] TiO 2 The preparation and battery performance test methods and steps of the photoanode are the same as those in Example 1.

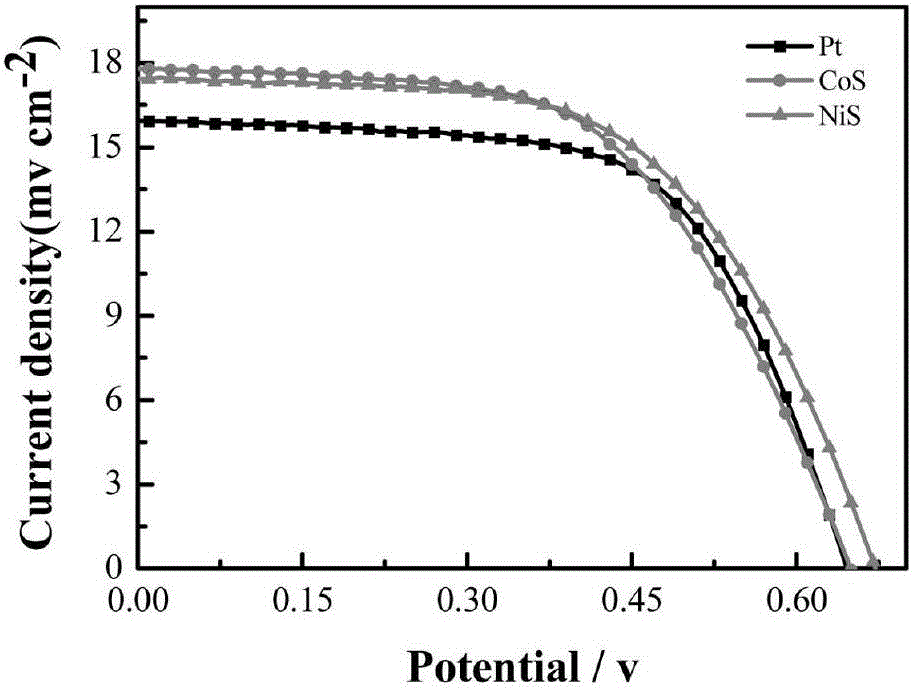

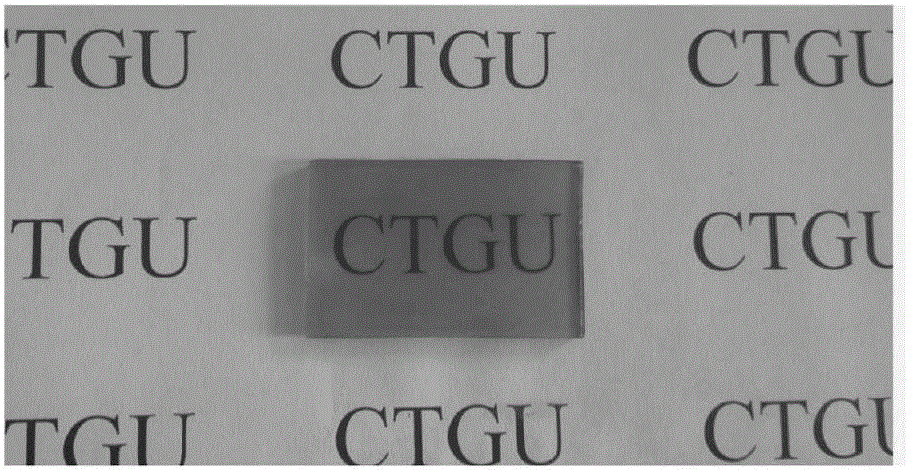

[0029] The J-V curve obtained from the performance test of the dye-sensitized solar cell assembled by the sample as the counter electrode is as follows: figure 1 Shown. It can be seen that the conversion efficiency reaches 6.79%, which is higher than the 6.44% conversion efficiency of the Pt counter electrode. Light transmittance such as image 3 Shown.

Embodiment 3

[0030] Example 3 The molar ratio is cobalt acetate tetrahydrate: thiourea is 1:1. The prepared CoS counter electrode preparation molar ratio is cobalt acetate tetrahydrate: thiourea is 1:1, and the volume ratio of ammonia to ethanol is 4:3 mixed solution, pour it into the reactor, put the FTO conductive glass into the reactor (the conductive surface is down), react at 180°C for 18 hours, rinse the obtained FTO sample with ethanol, and dry it to obtain electrode.

[0031] TiO 2 The preparation and battery performance test methods and steps of the photoanode are the same as those in Example 1.

[0032] The J-V curve obtained from the performance test of the dye-sensitized solar cell assembled by the sample as the counter electrode is as follows: Figure 4 Shown. It can be seen that the conversion efficiency reaches 6.35%, which is approximately equal to the conversion efficiency of Pt to the electrode 6.39%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com