Semiconductor memory and manufacture method thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as slow response speed, slow memory response speed, and easy loss of charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

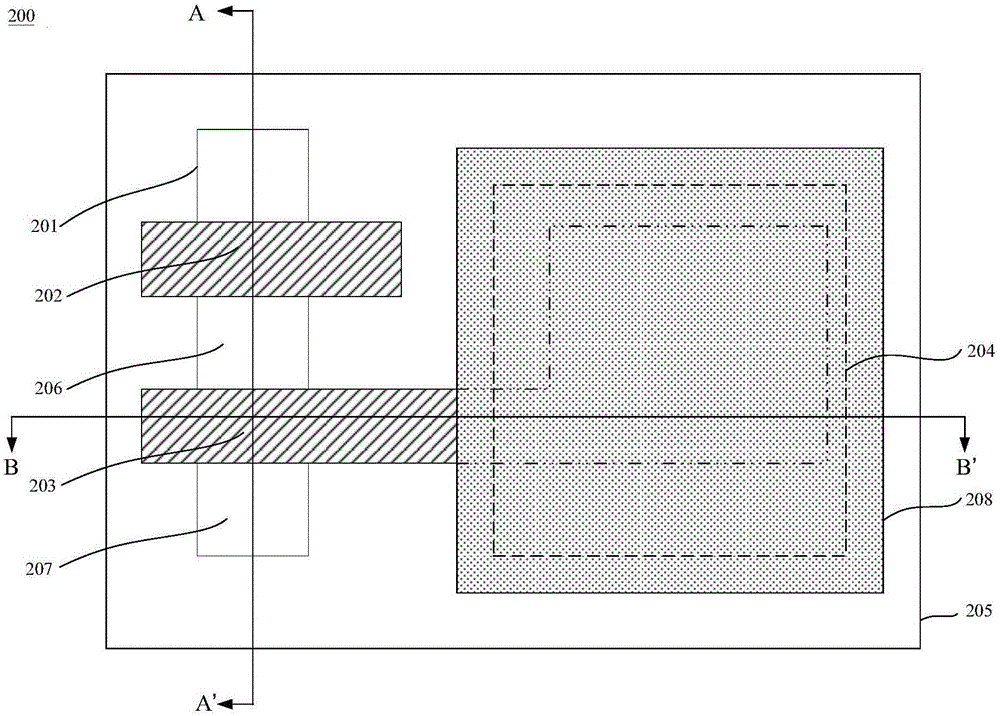

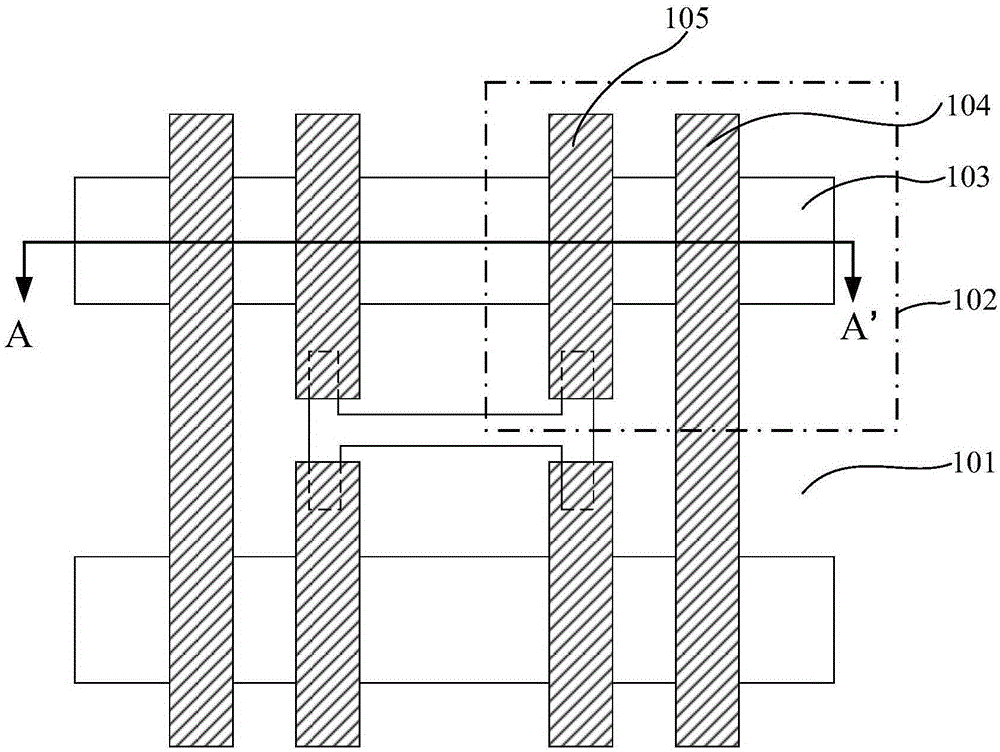

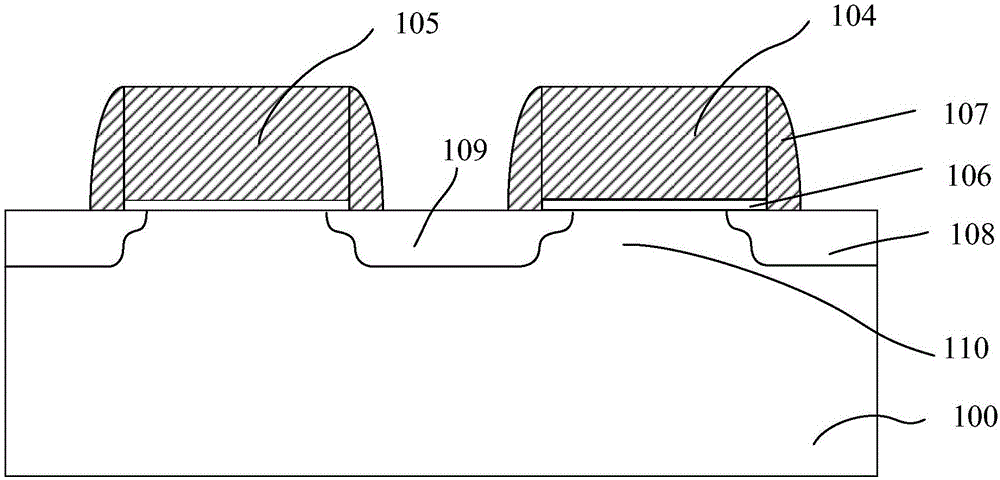

[0057] The working principle of traditional semiconductor memory is to directly apply a voltage on the floating gate, and inject the charge in the channel into the floating gate through the tunnel oxide layer through the vertical electric field of the channel, which has the defects of high working voltage and slow reaction rate. ; At the same time, there is no protective layer on the surface of the floating gate, and the injected charges are easily lost through the surface of the floating gate, thereby weakening the data storage capacity of the memory.

[0058] After research and analysis by the inventors of the present invention, it is found that sequentially forming an inter-gate dielectric layer and a control gate on the surface of the floating gate can solve the performance defects of the traditional semiconductor memory. Taking a P-type device as an example, a negative voltage of -0.7 volts to -2.3 volts is applied to the control gate. Under the voltage range, more hot ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com