Preparation method of sulfur/porous carbon composite cathode material

A composite positive electrode material and porous carbon technology, which is applied in battery electrodes, electrical components, non-aqueous electrolyte batteries, etc., can solve the problems of low sulfur content of composite positive electrode materials, difficulty in further improving the energy density of lithium-sulfur batteries, and small specific surface area, etc. Achieve improved electrochemical performance, good reversibility and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

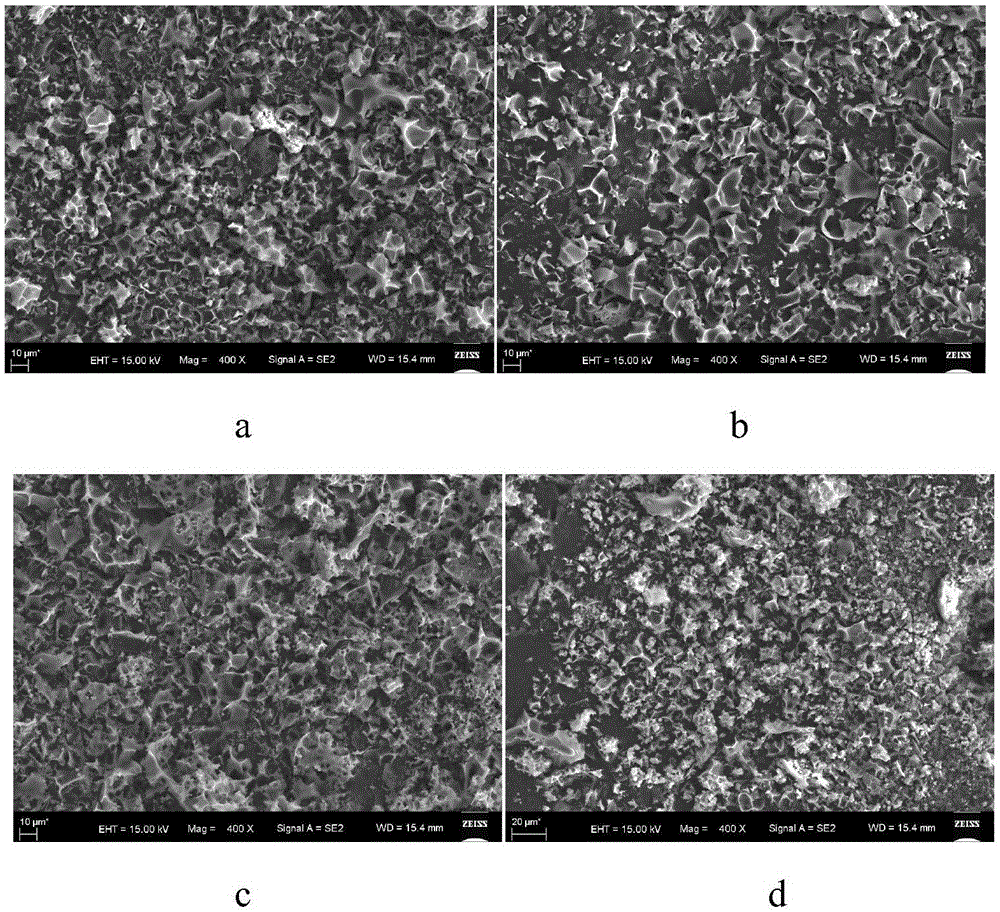

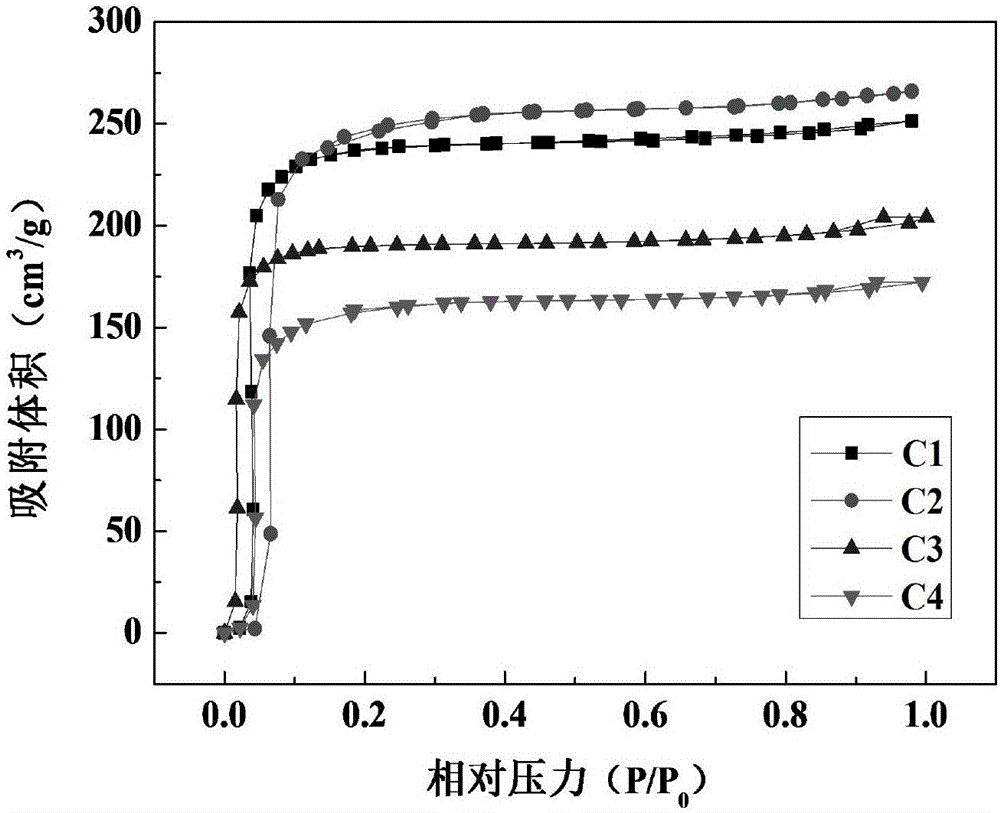

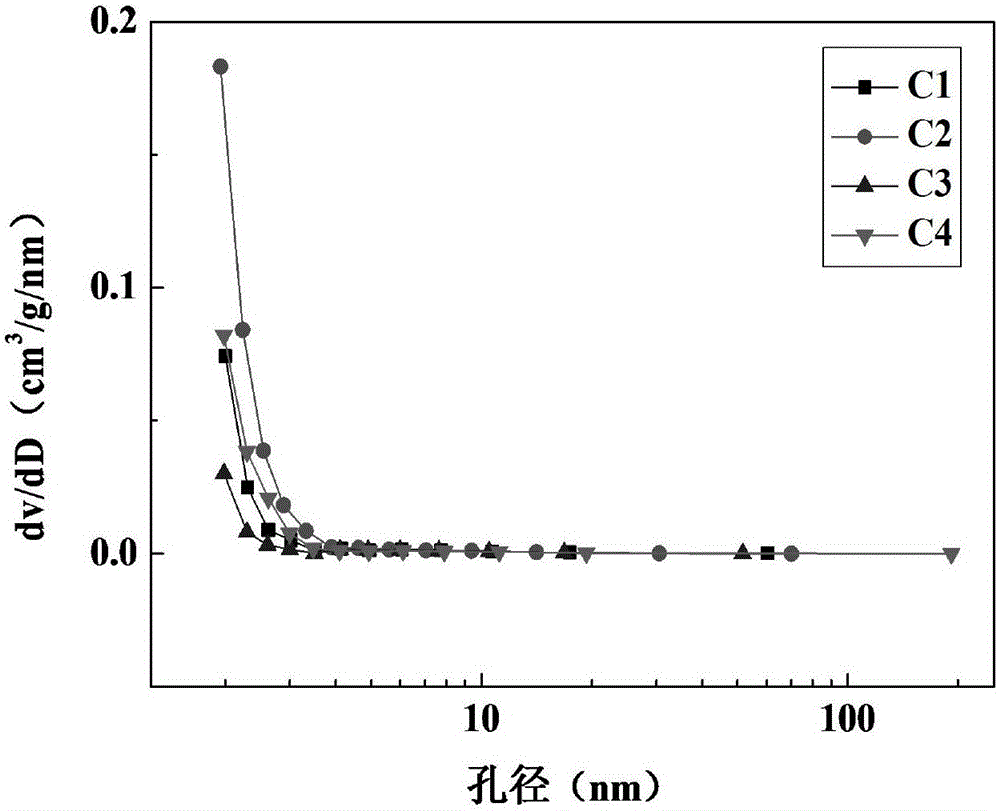

[0030] The present invention provides a kind of preparation method of novel sulfur / porous carbon composite cathode material, comprising the following steps: (1) hydrothermal pre-carbonization: take a certain amount of glucose and dissolve it in deionized water, add organic nitrogen from the solution After stirring and mixing evenly, transfer it to the reaction kettle. After hydrothermal reaction at a certain temperature for a certain period of time, take it out after cooling to room temperature, filter and wash with deionized water, then wash with absolute ethanol, and dry it with air at 50°C for 24 hours to prepare Nitrogen doped precursor.

[0031] (2) Activation: Mix the nitrogen-doped precursor prepared in step 1 with the pore-enlarging agent in a certain mass ratio, add deionized water, stir at 70°C, take it out and put it in a porcelain boat after it becomes viscous dry. Finally, it is calcined for a certain period of time under the protection of inert gas in a high-tem...

Embodiment 1

[0042] (1) Weigh 16.0g of glucose and dissolve it in 40.0mL of deionized water, add 1.5g of acetamide in the solution, stir and mix, transfer to a 50mL reaction kettle, perform hydrothermal reaction at 200°C for 5h, take it out after cooling at room temperature, and remove The nitrogen-doped precursor was prepared by filtering and washing with deionized water, then washing with absolute ethanol, and air-drying at 50° C. for 24 hours.

[0043](2) Mix the nitrogen-doped precursor and KOH at a mass ratio of 1:3, add a certain amount of deionized water, and stir at 70°C (1g precursor plus 20mL deionized water), take it out and put it in a porcelain boat after it becomes viscous Dry at 80°C for 24h. Finally in N 2 Calcined in a tube furnace at 500°C under protection for 2 hours, then cooled and taken out. Add a certain amount of deionized water and sonicate for 30 minutes, then add absolute ethanol and sonicate for 30 minutes, filter and dry with suction to obtain a nitrogen-dope...

Embodiment 2

[0046] (1) Weigh 16.0g of glucose and dissolve it in 40.0mL of deionized water, add 2.0g of acetamide in the solution, stir and mix, transfer to a 50mL reaction kettle, perform hydrothermal reaction at 220°C for 5h, take it out after cooling at room temperature, and remove The nitrogen-doped precursor was prepared by filtering and washing with deionized water, then washing with absolute ethanol, and air-drying at 50° C. for 24 hours.

[0047] (2) Mix the nitrogen-doped precursor and KOH at a mass ratio of 1:4, add a certain amount of deionized water and stir at 70°C (1g precursor plus 20mL deionized water), take it out and put it in a porcelain boat after it becomes viscous Dry at 80°C for 24h. Finally in N 2 Calcined in a tube furnace at 600°C under protection for 2 hours, then cooled and taken out. Add a certain amount of deionized water and sonicate for 30 minutes, then add absolute ethanol and sonicate for 30 minutes, filter and dry with suction to obtain a nitrogen-dope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com