Quizalofop-p-ethyl containing water dispersible granule and preparation method thereof

A technology of quizalofop-p-ethyl and dispersible granules, which is applied in botany equipment and methods, biocides, biocides, etc., can solve the problems of 60% WG poor efficacy and unsatisfactory use effect, and achieve dispersibility and stability Good performance, reduced Gibbs free energy, fast disintegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

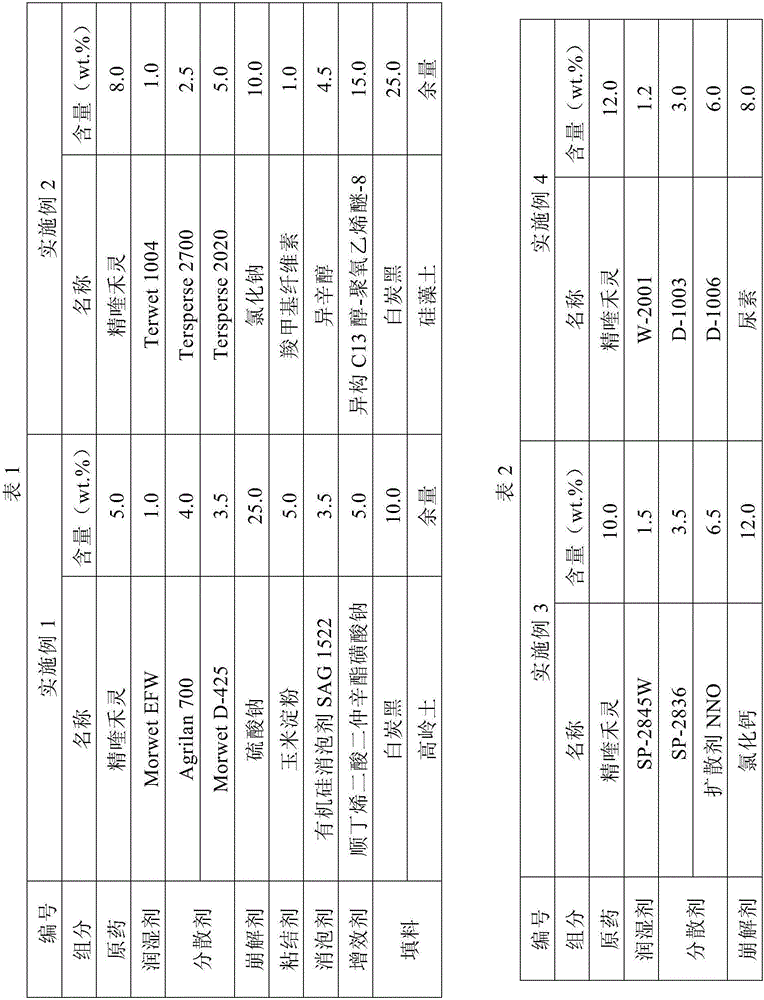

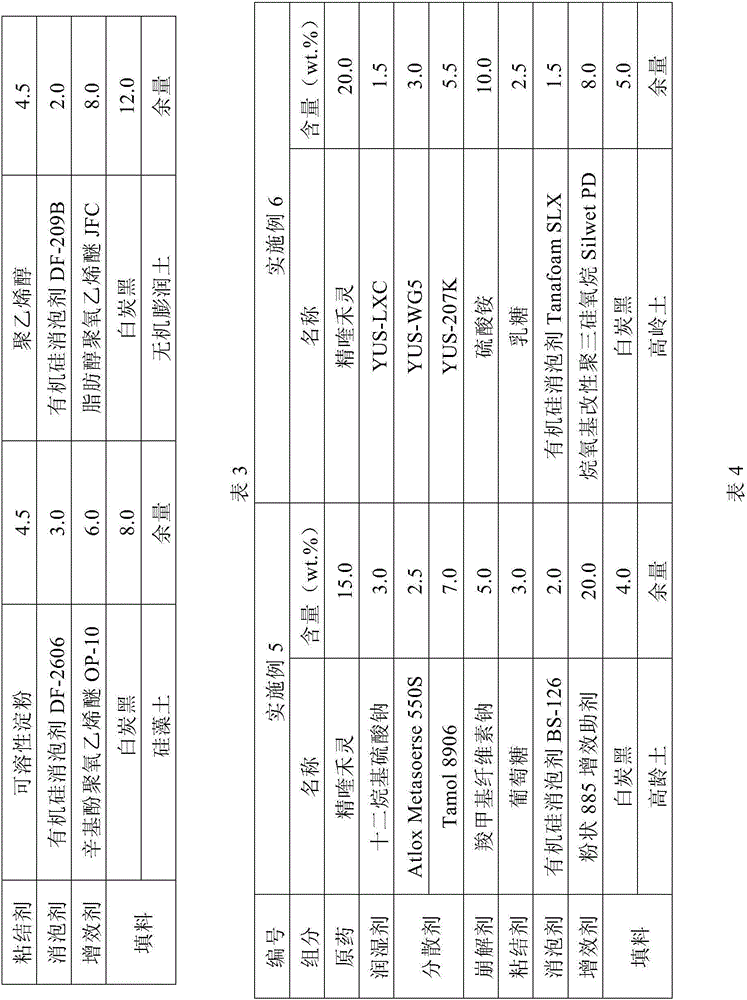

Embodiment 1~6

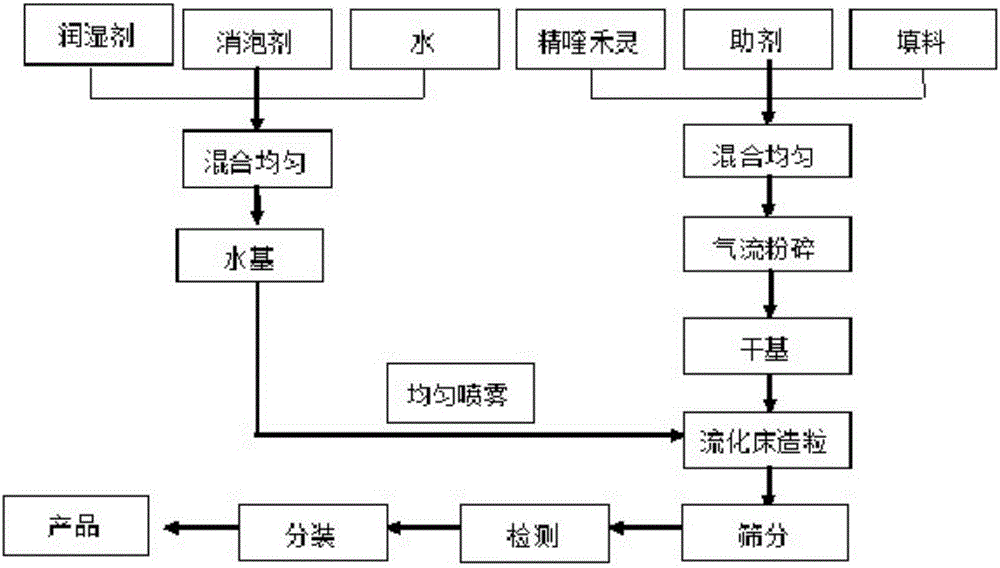

[0040] Embodiment 1~6 each component content is as shown in table 1~3, and the step of preparing quizalofop-p-ethyl water-dispersible granule is as follows (process flow chart sees figure 1 ):

[0041] 1) According to the content requirements of the components, quizalofop-p-p-p, dispersant, disintegrating agent, binder, synergist and filler are mixed evenly, and then pulverized by a jet mill to obtain a dry basis, wherein the dry The crushing fineness of the base is controlled as follows: the amount passing through the 45μm test sieve is ≥95%;

[0042] 2) The wetting agent and the defoaming agent are formulated into an aqueous solution to obtain a water base;

[0043] 3) Spray the water base through a nozzle onto the dry base placed on a fluidized bed for granulation. The whole process of granulation and drying is completed on the fluidized bed.

[0044] 4) The prepared granules are screened, tested and packaged to obtain the quizalofop-p-ethyl water-dispersible granules. ...

Embodiment 7

[0056] Embodiment 7 field efficacy test

[0057] Use the quizalofop-p-ethyl water-dispersible granules prepared in Examples 1 to 6, apply the drug according to the active ingredient dosage of 60 grams / hectare, repeat 4 times for each treatment, prevent and control the annual grass weeds in the cotton field, and investigate respectively after the application 15 days and 30 days strain control effect and fresh weight control effect, investigation result compares with contrast medicament 5% quizalofop-ethyl emulsifiable concentrate (commercially available), 20% quizalofop-p-ethyl water-dispersible granule (commercially available), the results see Table 5-7.

[0058] The annual gramineous weeds in the cotton experimental field were mainly crabgrass, foxtail, barnyardgrass and goosegrass. The experimental plots were randomly arranged, and the area of each plot was 25 square meters.

[0059] The drug efficacy calculation method is as follows:

[0060] Plant control effect (%)=(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com