Compound air filter membrane based on chitosan and graphene oxide and preparation method of compound air filter membrane

A graphene composite, air filter membrane technology, applied in the field of air purification, can solve the problems of limited adsorption capacity of activated carbon, limited sterilization effect, low adsorption efficiency of solid particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

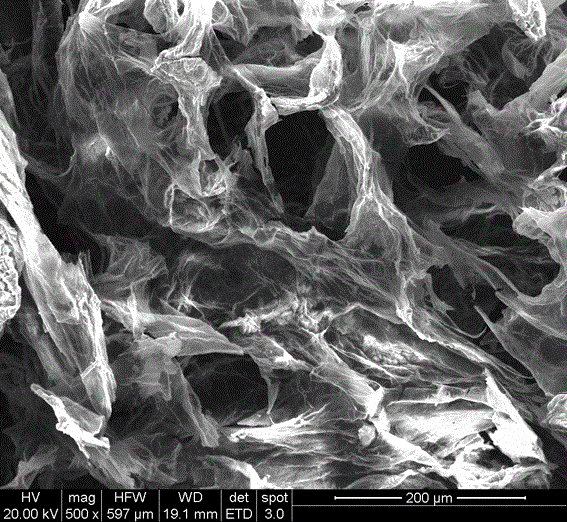

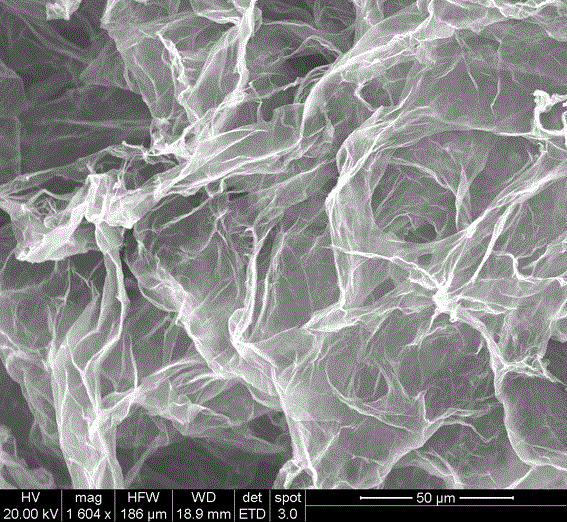

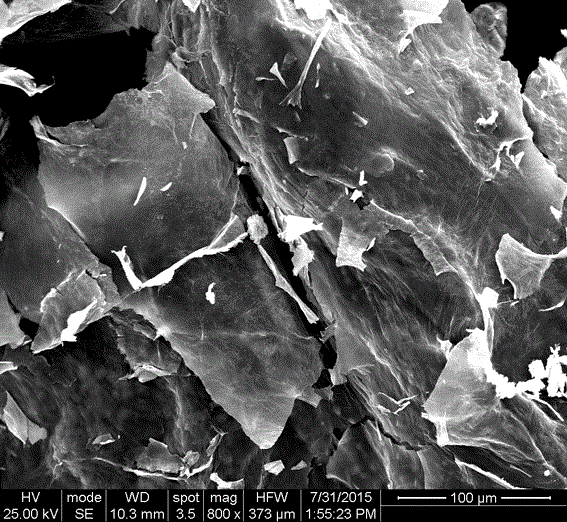

Image

Examples

Embodiment 1

[0053] The preparation method of the composite air filter membrane of embodiment 1 chitosan and graphene oxide

[0054] A composite air filter membrane based on chitosan and graphene oxide is characterized in that it comprises a sponge carbon membrane; on the sponge carbon membrane, chitosan is composited with graphene oxide to form a chitosan composite on the surface of the sponge carbon membrane Graphene oxide homogeneous membrane. The preparation steps of the composite air filter membrane of chitosan and graphene oxide are as follows:

[0055] (1) Preparation of sponge carbon film: Polyurethane and 200-mesh activated carbon powder were mixed and compression-molded at a mass ratio of 3:1 to obtain a sponge carbon film. The compression-molding condition was 3Mpa, the temperature was controlled at 210°C, and the preparation was obtained by controlling the compression-molding gap. The thickness of the carbon sponge film is 0.4cm, and the micropores of 1-3mm are evenly distribu...

Embodiment 2

[0061] The preparation method of the composite air filter membrane of embodiment 2 chitosan and graphene oxide

[0062] A composite air filter membrane based on chitosan and graphene oxide is characterized in that it includes a sponge carbon membrane; on the sponge carbon membrane, chitosan is composited with graphene oxide to form a chitosan composite on the surface of the sponge carbon membrane Graphene oxide homogeneous membrane. The preparation steps of the composite air filter membrane of chitosan and graphene oxide are as follows:

[0063] (1) Preparation of sponge carbon film: Polystyrene and 200-mesh activated carbon powder were mixed and compressed at a mass ratio of 3:1 to obtain a sponge carbon film. The compression molding condition was 5Mpa, and the temperature was controlled at about 210°C. The thickness of the carbon sponge film obtained by gap preparation is 0.5cm, and the micropores of 1-3mm are evenly distributed on the carbon sponge film prepared in this wa...

Embodiment 3

[0069] Embodiment 3 organic pollutant absorption test

[0070] to combine Figure 5 , the test object is the sponge carbon membrane prepared in Example 1, the composite air filter membrane (hereinafter referred to as the composite membrane) based on chitosan and graphene oxide prepared in Example 1, using 3 cubic meters of organic volatile matter absorption test box, first add formaldehyde, toluene and sulfur dioxide and other organic volatiles into the test box, use the built-in fan to make them completely volatilize, then put the test sample filter membrane, turn on the built-in fan, perform internal air circulation and convection, and use the built-in TVOC detector to detect VOC content, record the film’s absorption of TVOC every 10 minutes, the test data is shown in the table below, and the data is processed to obtain the absorption curve of organic volatile pollutants ( Figure 5 ), it can be seen that the absorption rate of the composite membrane is 2-4 times higher tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com