Composite photocatalyst, and preparation method and application thereof

A catalyst and composite light technology, applied in the field of photocatalysis, can solve the problem of low utilization rate of solar energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of composite photocatalyst, comprises the following steps:

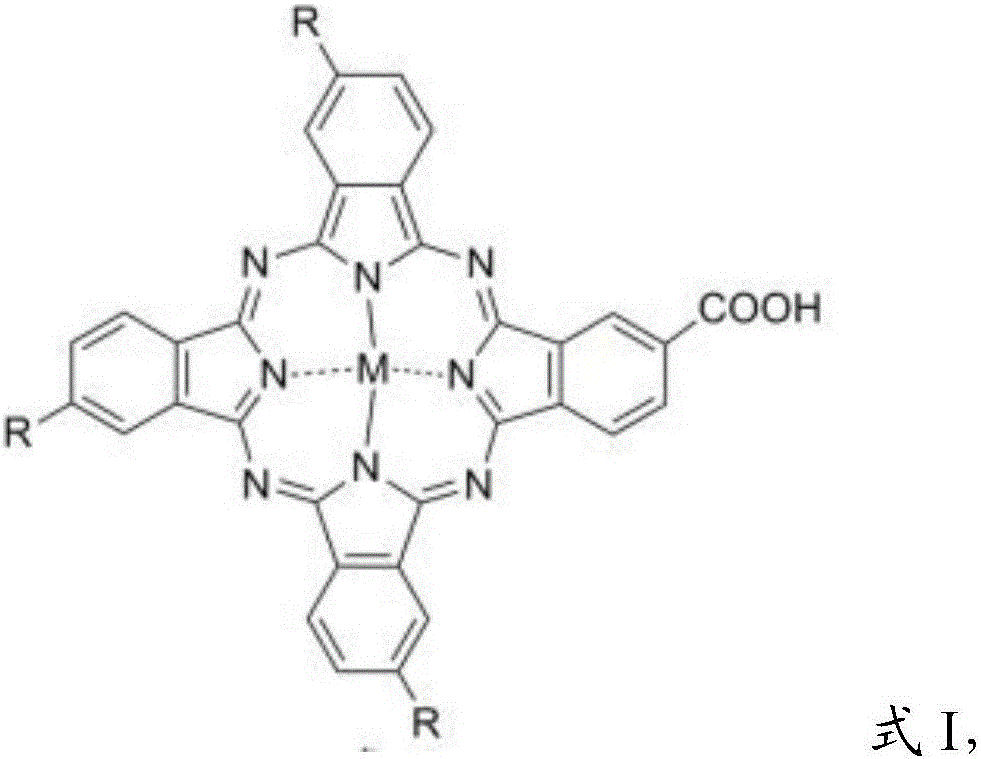

[0026] (1) graphite phase carbon nitride is mixed with an aprotic organic solvent to obtain a graphite phase carbon nitride dispersion; metal phthalocyanine with a structure described in formula I, a condensing agent, an alkali agent and an aprotic organic solvent are mixed to obtain Metal phthalocyanine solution;

[0027] (2) Adding the graphite phase carbon nitride dispersion in the step (1) dropwise to the metal phthalocyanine solution, heating the obtained reaction solution to carry out condensation reaction, to obtain a composite photocatalyst precursor;

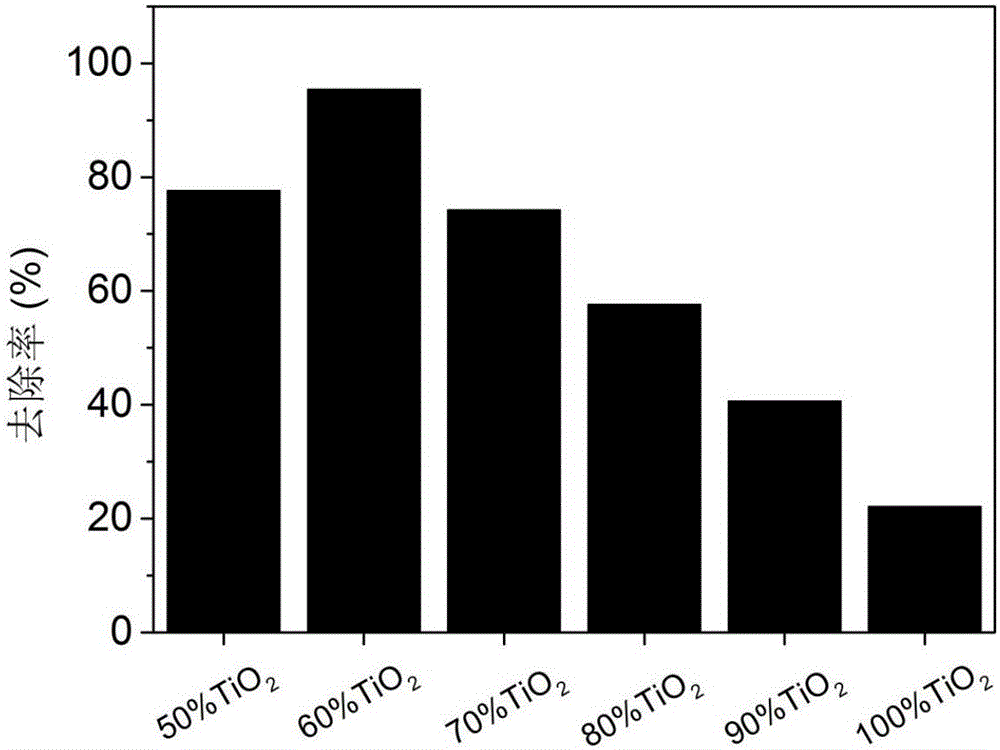

[0028] (3) composite photocatalyst precursor and TiO in described step (2) 2 Mixed with water, composited under ultrasonic conditions to obtain the composite photocatalyst.

[0029] The invention mixes graphite phase carbon nitride with aprotic organic solvent to obtain graphite phase carbon nitride ...

Embodiment 1

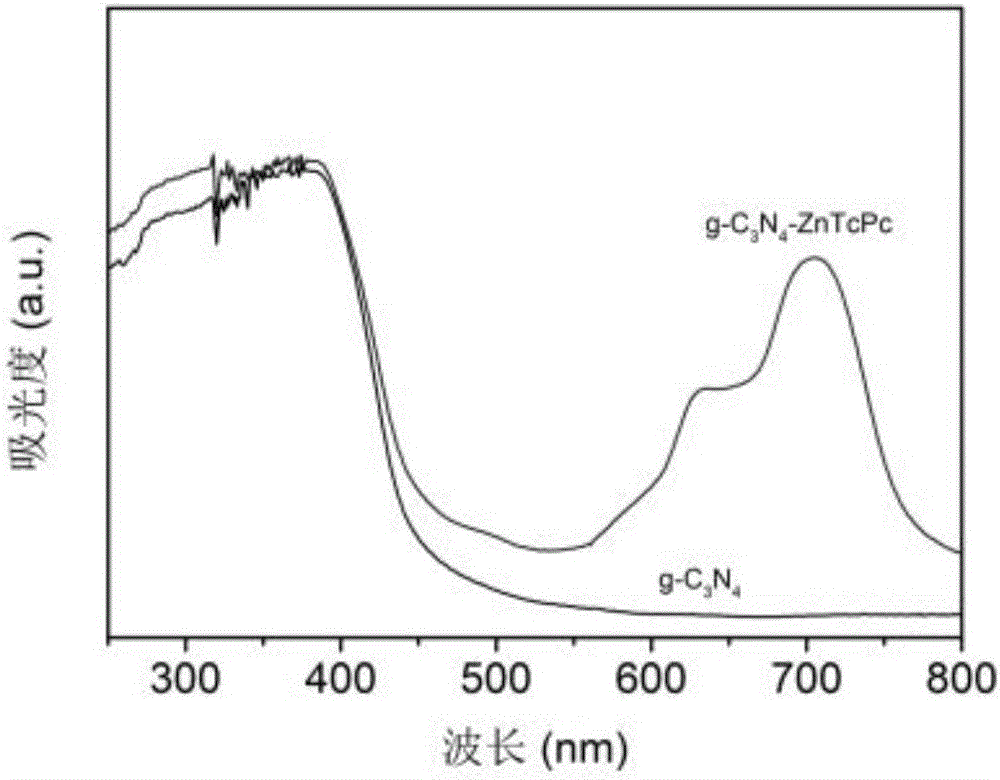

[0063] (1) Put 15g of urea in a semi-closed alumina crucible with a lid, raise the temperature to 550°C at a rate of 1°C / min in a tube furnace and maintain it for 4h to obtain g-C 3 N 4 ;

[0064] Tetracarboxyzinc phthalocyanine (ZnTcPc) is prepared according to the method for synthesizing tetracarboxycobalt phthalocyanine in the reference (Pan Yong. Novel metal phthalocyanine and its thermosensitive polymer synthesis and imitation enzyme catalytic performance. Zhejiang University, 2005.): Specific steps are as follows:

[0065] Mix 9g of trimellitic anhydride, 15.0g of urea, 4.3g of zinc chloride and 0.115g of ammonium molybdate, grind them, transfer them to a 500mL beaker, heat them in an oven to 130°C and keep the temperature constant until the foaming phenomenon stops Finally, the temperature was raised to 185°C, and a blue-black solid was obtained after a constant temperature reaction for 4 hours; the obtained product was crushed and added to 250 mL of 1.0 mol / L hydroch...

Embodiment 2

[0071] (1) Put 15g of urea in a semi-closed alumina crucible with a lid, raise the temperature to 550°C at a rate of 1°C / min in a tube furnace and maintain it for 4h to obtain g-C 3 N 4 ;

[0072] (2) Put g-C in step (1) 3 N 4 1.0g was mixed with 60mL N,N-dimethylformamide, sonicated at 400W for 24h to obtain g-C 3 N 4 Dispersion liquid; prepare tetracarboxyzinc phthalocyanine according to the method in Example 1, get tetracarboxyzinc phthalocyanine 50mg, (3H-1,2,3-triazolo[4,5-b]pyridine-3-oxyl ) 400mg of tris-1-pyrrolidinyl hexafluorophosphate, 1g of N,N-diisopropylethylamine and 120mL of N,N-dimethylformamide were mixed, ultrasonicated at 400W for 10h to obtain tetracarboxyzinc phthalocyanine dispersion ;

[0073] (3) Add 60mL of graphite phase carbon nitride dispersion liquid in step (2) dropwise to 120mL tetracarboxyzinc phthalocyanine solution at a rate of 100mL / h, react at 50°C for 6h, and use G6 Filter through a sand core funnel, wash twice with N,N-dimethylform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com