Harmless livestock corpse processing device

A technology for processing equipment and livestock carcasses, which is applied in the field of harmless livestock carcass treatment equipment, can solve problems such as ineffective cooling of tap water, endangering the health of surrounding residents, and interfering with the normal life of residents, so as to improve efficiency, save fuel, save effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

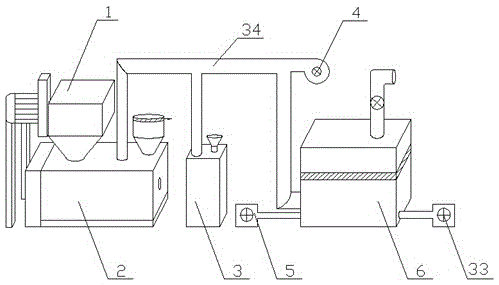

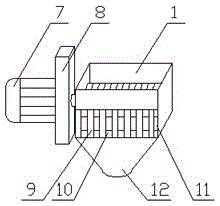

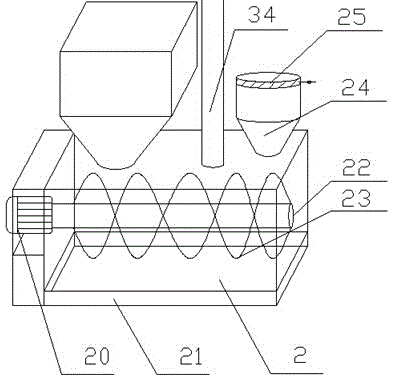

[0014] A harmless livestock carcass processing equipment, characterized in that it includes a pulverizer 1, a high-temperature mixer 2, a grinder 3, an induced draft fan 4, a cooling water pipe 5, a biological deodorization device 6, a pulverizing motor 7, a transmission device 8, a pulverizing machine Blade 9, fixed blade 10, metal spacer 11, material delivery port 12, cooling water inlet 13, gas inlet 14, cooling water outlet 15, cooling water 16, biological deodorizing net 17, air exhaust device 18, exhaust pipe 19, Stirring motor 20, electromagnetic heating plate 21, stirring shaft 22, stirring auger 23, biological enzyme inlet 24, sealing cover 25, bracket 26, grinding chamber 27, grinding motor 28, transmission belt 29, grinding paddle 30, eggshell inlet 31, Sealing valve 32, cooling water valve 33, air guide pipe 34, the high temperature mixer 2 is connected below the pulverizer 1, the air guide pipe 34 is installed above the high temperature mixer 2, and the air guide p...

Embodiment 2

[0016] The worker puts the livestock carcass into the pulverizer 1, the pulverizing motor 7 drives the pulverizing blade 9 to move through the transmission mechanism 8, the pulverizing blade 9 rotates and passes through the cutting edge interlaced with the fixed blade 10 to pulverize it, and the pulverized corpse passes through the feeding port 12 falls into the high-temperature mixer 2, and the worker sends the biological enzyme into the high-temperature mixer 2 through the biological enzyme inlet 24, and then seals the sealing cover 25 tightly to prevent the gas generated from leaking out, and the stirring motor 20 drives the stirring shaft 22 to rotate, so that the stirring shaft The dragon 23 re-crushed the crushed corpse, and at the same time, the electromagnetic heating plate 21 heated up rapidly, and the induced draft fan 4 introduced the gas generated during the decomposition of the biological enzyme into the biological deodorization device 6 through the air duct 34, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com