Microwave copper-clad plate preparation method capable of keeping low thermal expansion coefficient in three axes at the same time

A low thermal expansion coefficient, shaft retention technology, applied in chemical instruments and methods, lamination, adhesives, etc., can solve the problems of limited adjustable range of dielectric constant, large difference, etc., to improve the lack of rigidity, low production cost, low cost The effect of dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides a method for preparing a microwave copper-clad laminate with low thermal expansion coefficient in three axes, wherein the three axes refer to the X, Y, and Z axes of the impregnated dielectric board. The preparation method of microwave copper clad laminate comprises the following steps:

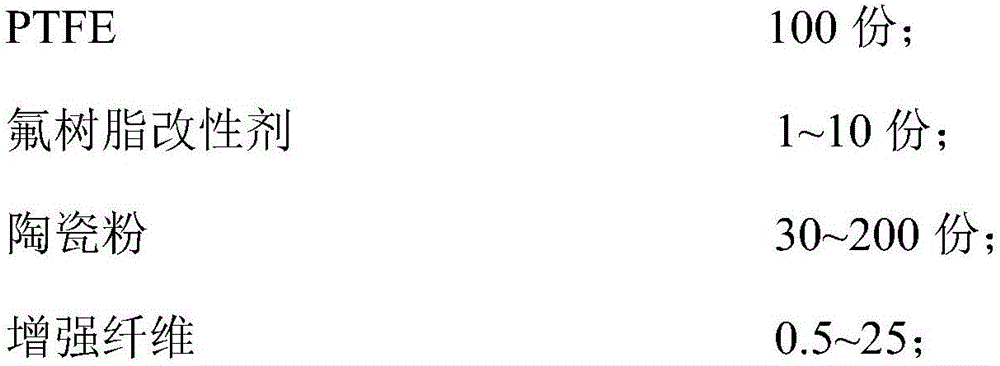

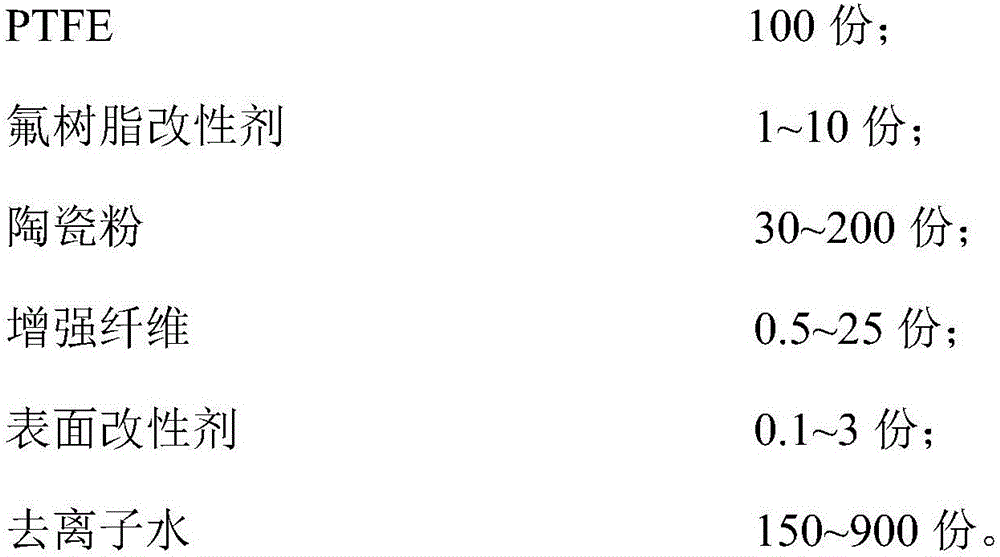

[0028] Step (1), prepare the adhesive sheet, the preparation method of the adhesive sheet is: add appropriate amount of fluororesin to modify the PTFE emulsion, add mixed ceramic powder, reinforcing fiber and a certain amount of surface modifier, dilute with deionized water into different Concentration and viscosity, stir evenly, such as heating and stirring in a high-speed mixer at 20-70°C for 10-60min, the stirring speed is 1000-3000rpm; immerse the PTFE porous membrane in the above-mentioned uniform solution of different concentrations for 10-30s, 2 to 5 times the solution, adjusted to the predetermined thickness. Dry the dipped film at 50-120°C for 2...

Embodiment 1

[0051] (1) According to each component specified in Example 1 in Table 1, add FEP, amorphous SiO in PTFE emulsion 2 and surface modifier F8261, diluted with deionized water to a concentration of 35% solid content, stirred in a high-speed mixer at 20°C for 10min, and the stirring speed was 1000rpm. The solvent is configured into different concentrations of 85%, 70%, 50%, 30%, and 15%, so that the PTFE porous membrane with a thickness of 40 μm and a porosity of 80% is immersed in the above-mentioned solution according to the concentration from high to low, A total of 5 times of dipping for 30s each time. Dry the dipped film at 50°C for 5 minutes to remove moisture, then dry at 200°C for 5 minutes to remove low-temperature volatiles such as dispersants, and finally dry at 370°C for 20 minutes to obtain an adhesive sheet with uniform thickness and smooth surface.

[0052] (2) The preparation method of the microwave copper-clad laminate is as follows: stack five adhesive sheets ob...

Embodiment 2

[0054] (1) according to each component specified in embodiment 2 in table 1 respectively, add PFA, amorphous SiO in PTFE emulsion 2 、Al 2 o 3 , glass microfiber, surface modifier F8261 and AN, diluted with deionized water to a concentration of 40% solid content, stirred in a high-speed mixer at 40°C for 20min, and the stirring speed was 2000rpm. The solvent is configured into different concentrations of 80%, 65%, 40%, and 20%, so that the PTFE porous membrane with a thickness of 40 μm and a porosity of 80% is immersed in the above solutions in order from high to low in concentration. A total of 4 times of immersion in 20s. Dry the dipped film at 80°C for 3 minutes to remove moisture, then dry at 300°C for 3 minutes to remove low-temperature volatiles such as dispersants, and finally dry at 380°C for 15 minutes to obtain an adhesive sheet with uniform thickness and smooth surface.

[0055] (2) The preparation method of the microwave copper-clad laminate is as follows: stack ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com