Method for removing methylene blue from dye wastewater

A methylene blue, dye wastewater technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., to achieve high process efficiency, reuse adsorption performance, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

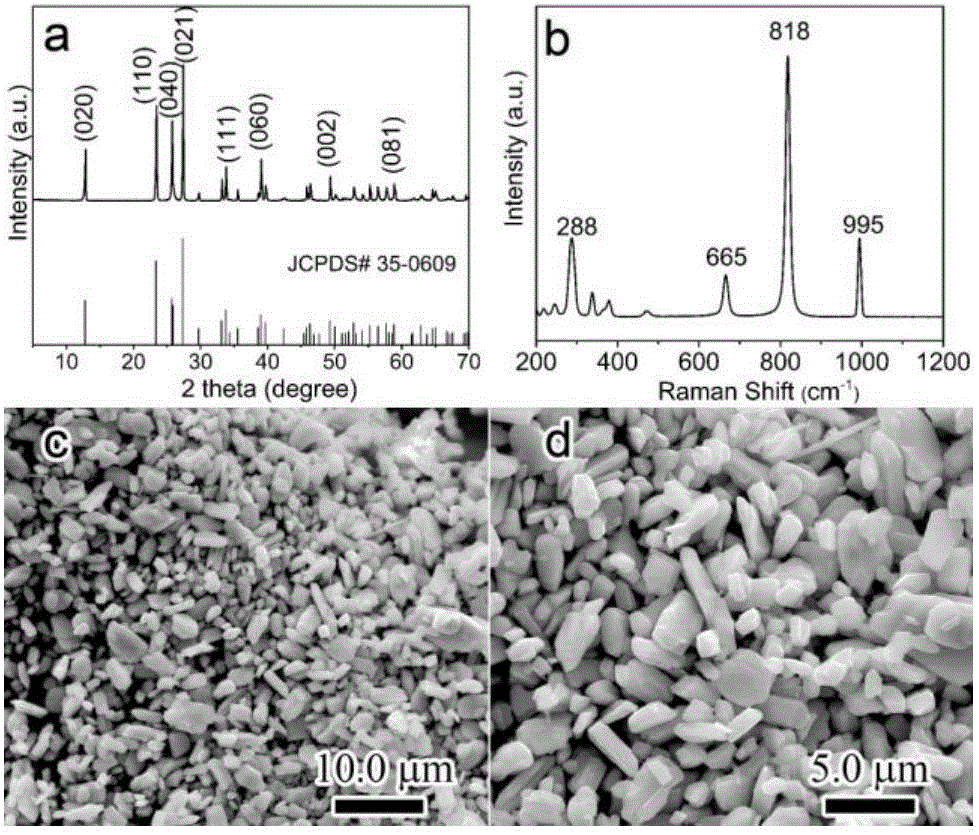

[0020] α-MoO 3 Particle preparation:

[0021] 10g of commercialized ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) put into an evaporating dish, place it in a muffle furnace, rise from room temperature to 500°C at 5°C / min under an air atmosphere, and keep this temperature for 4h, and finally, drop to room temperature naturally under an air atmosphere, get α-MoO 3 particle.

Embodiment 2-13

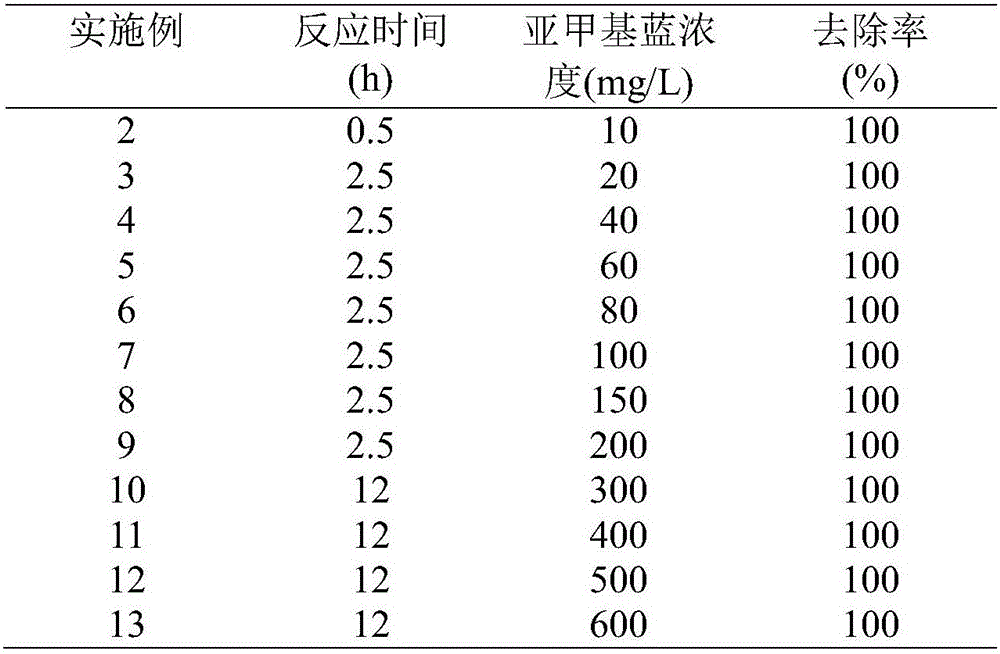

[0023] The material prepared in Example 1 was used to adsorb methylene blue in wastewater solution. Adsorption experiments were carried out in the dark to prevent the influence of light. 0.4 g of commercial α-MoO 3 and 100mL methylene blue solutions with concentrations of 10, 20, 40, 60, 80, 100, 150, 200, 300, 400, 500, 600mg / L were added to a 250mL Erlenmeyer flask, and the system was stirred and adsorbed at room temperature. Time (0.5-12h), after adsorption, the solution was centrifuged to take the upper clear night, and the absorbance was measured at the characteristic absorption wavelength of methylene blue at 664nm with a spectrophotometer Perkin ElmerLambda 750, and its composition was analyzed. The relevant results are shown in Table 1.

[0024] Table 1 α-MoO 3 Reaction result of particles adsorbing methylene blue wastewater solution

[0025]

[0026] As can be seen from Table 1: α-MoO 3 The particles can efficiently adsorb methylene blue in wastewater dyes. Wh...

Embodiment 14

[0028] The experimental procedure is the same as that in Example 7. After the adsorption is completed, separate the adsorbent from the solution, place it in a muffle furnace, and raise it from room temperature to 500°C at 5°C / min in an air atmosphere, and keep it at this temperature for 2h , finally, the air atmosphere is naturally lowered to room temperature, the adsorbed organic matter is removed, and the adsorbent α-MoO 3 Particle recovery. The experimental procedure of Example 7 was repeated, and a total of 4 repeated experiments were carried out. The adsorption experiment was repeated 4 times, and the removal rate of methylene blue in the wastewater was 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com