A method for preparing glucose and gallic acid by hydrothermally hydrolyzing tannin extract

A technology of gallic acid and glucose, applied in the field of chemical engineering, can solve the problems of environmental pollution equipment, corrosion, etc., and achieve the effect of high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

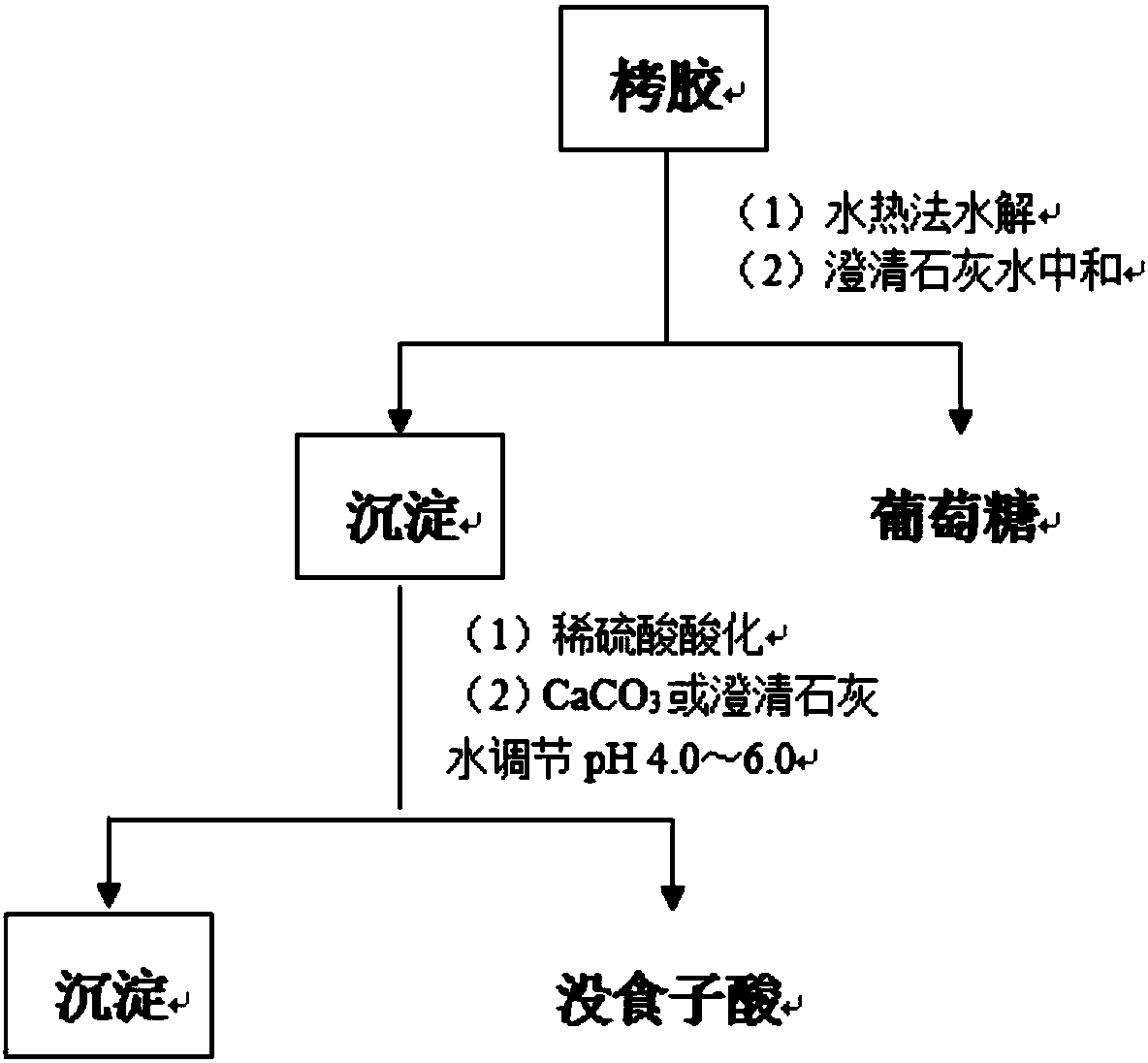

Method used

Image

Examples

Embodiment 1

[0026] The method for preparing glucose and gallic acid by hydrothermally hydrolyzing tannin extract in this embodiment comprises the following steps:

[0027] (1) Weigh 1 kg of tannin extract in a rubber bowl, add it to 10 L of water, stir and react for 0.5 h at a temperature of 120 °C and a pressure of 0.1 Mpa, and cool the reaction solution to room temperature;

[0028] (2) filtering the reaction solution described in step (1);

[0029] (3) The filtrate described in step (2) is neutralized with clarified lime water to generate a precipitate, which is filtered to obtain a solution and a precipitate;

[0030] (4) The filtrate described in step (3) is concentrated to 30% by three-effect downstream evaporation;

[0031] (5) The concentrated solution described in step (4) is centrifugally spray-dried to obtain glucose with a yield of 10% and a purity of 75%;

[0032] (6) acidify the precipitate described in step (3) with 0.1M dilute sulfuric acid solution, and then use CaCO 3...

Embodiment 2

[0036] The method for preparing glucose and gallic acid by hydrothermally hydrolyzing tannin extract in this embodiment comprises the following steps:

[0037] (1) Weigh 1kg of Huaxiangguo extract, add it to 25L of water, stir and react at a temperature of 240°C and a pressure of 2.8Mpa for 2.0h, and cool the reaction solution to room temperature;

[0038] (2) centrifuging the reaction solution described in step (1) for 20 min at a rotating speed of 1000 rpm / min;

[0039] (3) neutralize the centrifuged liquid described in step (2) with clarified lime water to generate a precipitate, and centrifuge for 20 min at a rotating speed of 1000 rpm / min to obtain a solution and a precipitate;

[0040] (4) The centrifugal liquid described in step (3) is concentrated to 40% by three-effect downstream evaporation;

[0041] (5) The concentrate in step (4) is spray-dried under pressure to obtain glucose with a yield of 8% and a purity of 70%;

[0042] (6) acidify the precipitate described ...

Embodiment 3

[0046] The method for preparing glucose and gallic acid by hydrothermally hydrolyzing tannin extract in this embodiment comprises the following steps:

[0047] (1) Weigh 1kg gallnut extract, add it to 20L water, stir and react for 1.0h at a temperature of 140°C and a pressure of 0.5Mpa, and cool the reaction solution to room temperature;

[0048] (2) centrifuging the reaction solution described in step (1) for 5 min at a rotating speed of 5000 rpm / min;

[0049] (3) neutralize the centrifuged liquid described in step (2) with clarified lime water to generate a precipitate, and centrifuge for 5 min at a rotating speed of 5000rpm / min to obtain a solution and a precipitate;

[0050] (4) The centrifugal liquid described in step (3) is concentrated to 32% by three-effect downstream evaporation;

[0051] (5) The concentrated solution in step (4) is spray-dried by air flow to obtain glucose, with a yield of 12% and a purity of 80%;

[0052] (6) acidify the precipitate described in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com