Light-emitting compound

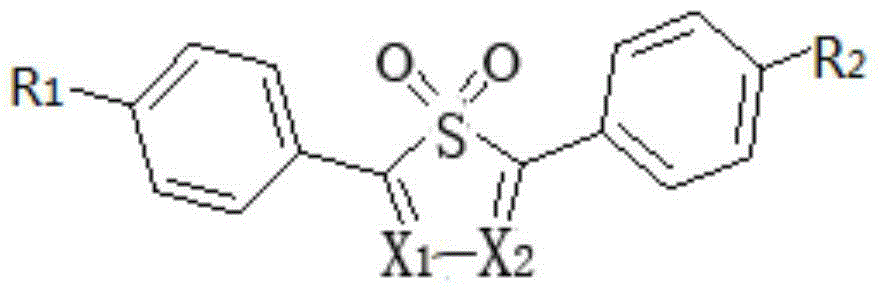

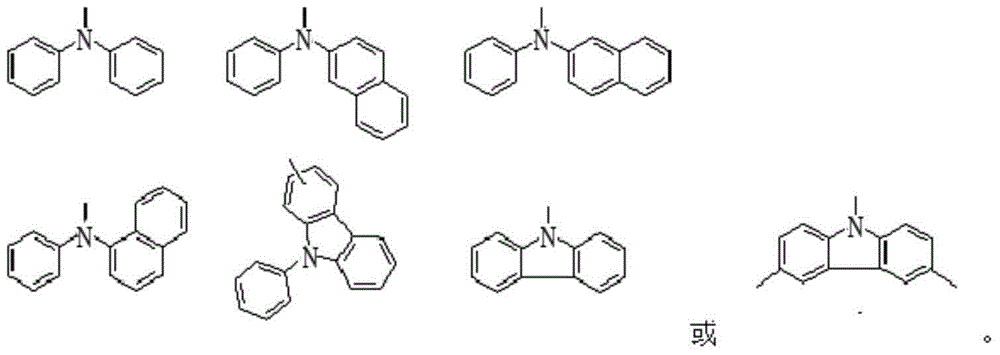

A technology of luminescent compounds and compounds, applied in luminescent materials, organic chemistry, chemical instruments and methods, etc., can solve the problems of lack of high-performance materials, achieve good thermal stability, increase electron transport performance, and increase thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

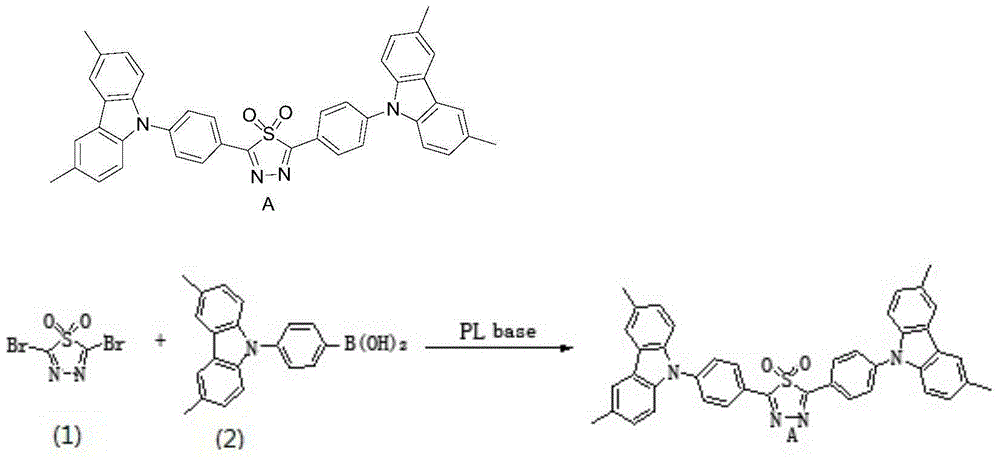

[0019] Embodiment 1 synthetic compound A

[0020]

[0021] Add compound (1) 0.1mol, compound (2) 0.1mol, 0.3mol potassium tert-butoxide, 0.015mol palladium catalyst and toluene (1000mL) in the reaction flask, heat and reflux under nitrogen protection for 24 hours, cool, remove toluene, add Dichloromethane, washed with water, dried, the crude product was passed through the column, and then recrystallized and purified with dichloromethane and ethanol to obtain the product, compound A, yield 27%, C42H32N4O2S, M=656.22, M+1=657.3 was detected.

Embodiment 2

[0022] Embodiment 2 synthetic compound B

[0023]

[0024] Add compound (3) 0.1mol, compound (4) 0.1mol, 0.3mol sodium phosphate, 0.025mol palladium catalyst and toluene (1000mL) in the reaction flask, heat and reflux under nitrogen protection for 24 hours, cool, remove toluene, add dichloro Methane, washed with water, dried, the crude product was passed through the column, and purified by recrystallization with dichloromethane and ethanol to obtain the product, compound 5, yield 53%, C18H11BrN2O2S, M=397.97, M+1=398.8 was detected.

[0025]

[0026] Add compound (5) 0.1mol, compound (6) 0.1mol, 0.3mol sodium bicarbonate, 0.005mol palladium catalyst and toluene (1000mL) in the reaction flask, under nitrogen protection, heat and reflux for 24 hours, cool, remove toluene, add di Chloromethane, washed with water, dried, the crude product was passed through the column, and then purified by recrystallization with dichloromethane and ethanol to obtain the product, compound B, ...

Embodiment 3

[0028] The device manufacturing process is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com