Preparation method of pawpaw seed oil

A technology of papaya seed oil and papaya seeds, which is applied in the direction of fat oil/fat refining, fat oil/fat production, fat production, etc., to achieve the effects of strong fragrance, increased extraction rate, and improved quality grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

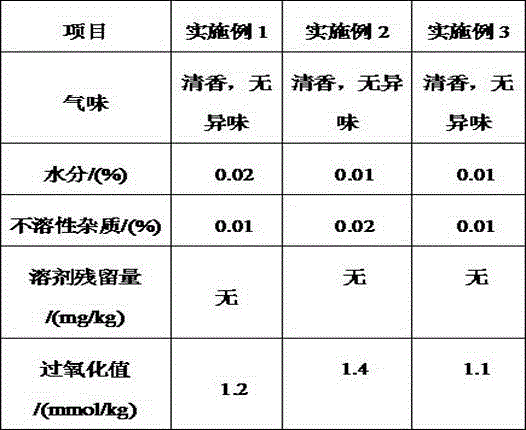

Examples

Embodiment 1

[0017] A preparation method of papaya seed oil, specifically comprising the following steps:

[0018] (1) Grinding: Select plump, mature, and pest-free papaya seeds. After winnowing and screening, wash them in clean water, drain, and crush to 80 meshes to obtain papaya seed powder. Add papaya seeds to the papaya seed powder Distilled water of 1.3 times the weight of the seeds, stirred evenly, to obtain papaya seed powder;

[0019] (2) Enzymolysis: Add complex enzymes to the papaya seed powder slurry to make the mass concentration 0.07%. After mixing evenly, stir and enzymolyze at 42°C for 240 minutes to destroy the cell structure, decompose macromolecular nutrients, and promote oil leaching. Boil on high heat until the water content is 25%, to obtain enzymatic hydrolyzed papaya seed powder;

[0020] (3) Extraction: Add an edible alcohol solution with a volume fraction of 80% twice the weight of the enzymatic papaya seed powder to the enzymatic hydrolyzed papaya seed powder. ...

Embodiment 2

[0026] A preparation method of papaya seed oil, specifically comprising the following steps:

[0027] (1) Grinding: Select plump, mature, pest-free papaya seeds, air-select and screen them, wash them in clean water, drain, and crush to 100 mesh to obtain papaya seed powder. Add papaya seeds to the papaya seed powder Distilled water of 1.4 times the weight of the seeds, stirred evenly, to obtain papaya seed powder;

[0028] (2) Enzymolysis: Add complex enzymes to the papaya seed powder slurry to make the mass concentration 0.08%. After mixing evenly, stir and enzymolyze at 43°C for 250 minutes to destroy the cell structure, decompose macromolecular nutrients, and promote oil leaching. Boil on high heat until the water content is 28%, to obtain enzymatic hydrolyzed papaya seed powder;

[0029] (3) Extraction: Add an edible alcohol solution with a volume fraction of 81% in an amount 2.5 times the weight of the enzymatic papaya seed powder to the enzymatic hydrolyzed papaya seed ...

Embodiment 3

[0035] A preparation method of papaya seed oil, specifically comprising the following steps:

[0036] (1) Grinding: Select plump, mature, pest-free papaya seeds, air-select and screen them, wash them in clean water, drain, and crush to 100 mesh to obtain papaya seed powder. Add papaya seeds to the papaya seed powder Distilled water of 1.5 times the weight of the seeds, stirred evenly, to obtain papaya seed powder;

[0037] (2) Enzymolysis: Add complex enzymes to the papaya seed powder slurry to make the mass concentration 0.09%. After mixing evenly, stir and enzymolyze at 44°C for 240~260 minutes to destroy the cell structure, decompose macromolecular nutrients, and promote oil production. Leaching, boiling on high heat until the water content is 25-30%, to obtain enzymatic hydrolyzed papaya seed powder;

[0038] (3) Extraction: Add an edible alcohol solution with a volume fraction of 82% in an amount three times the weight of the enzymatic papaya seed powder to the enzymatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com